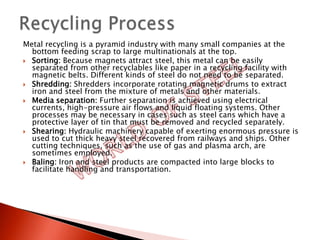

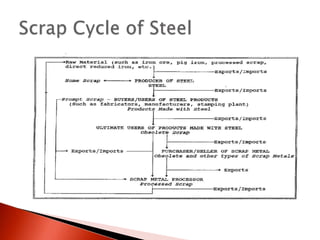

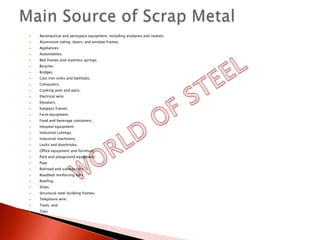

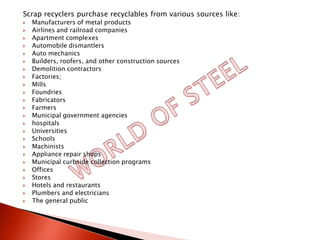

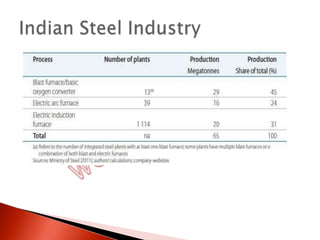

This document discusses scrap metal, which is a key raw material for steelmaking. It describes scrap metal as recyclable materials left over from product consumption. Scrap metal is divided into ferrous and nonferrous types, with ferrous scrap being iron and steel materials. Ferrous scrap is widely used in steelmaking as a raw material input and its use conserves natural resources. The document provides details on how scrap metal is collected, sorted, processed and used in steel production.