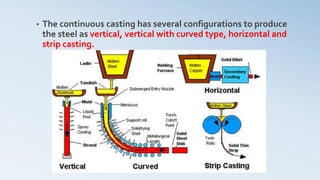

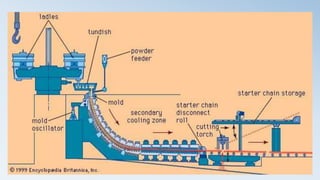

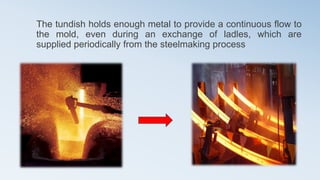

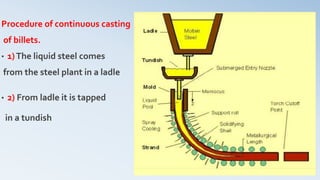

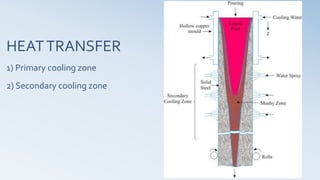

Continuous casting is a process that solidifies molten metal into a semi-finished billet, bloom, or slab for subsequent rolling. It involves pouring molten metal from a ladle into a tundish, then through a nozzle into a mold where it solidifies into a continuous strand. As the strand exits the mold, it passes through primary and secondary cooling zones before being bent and cut into final pieces. Continuous casting is now the dominant production method for metals like steel due to benefits like improved yield, quality, and energy efficiency compared to batch casting.