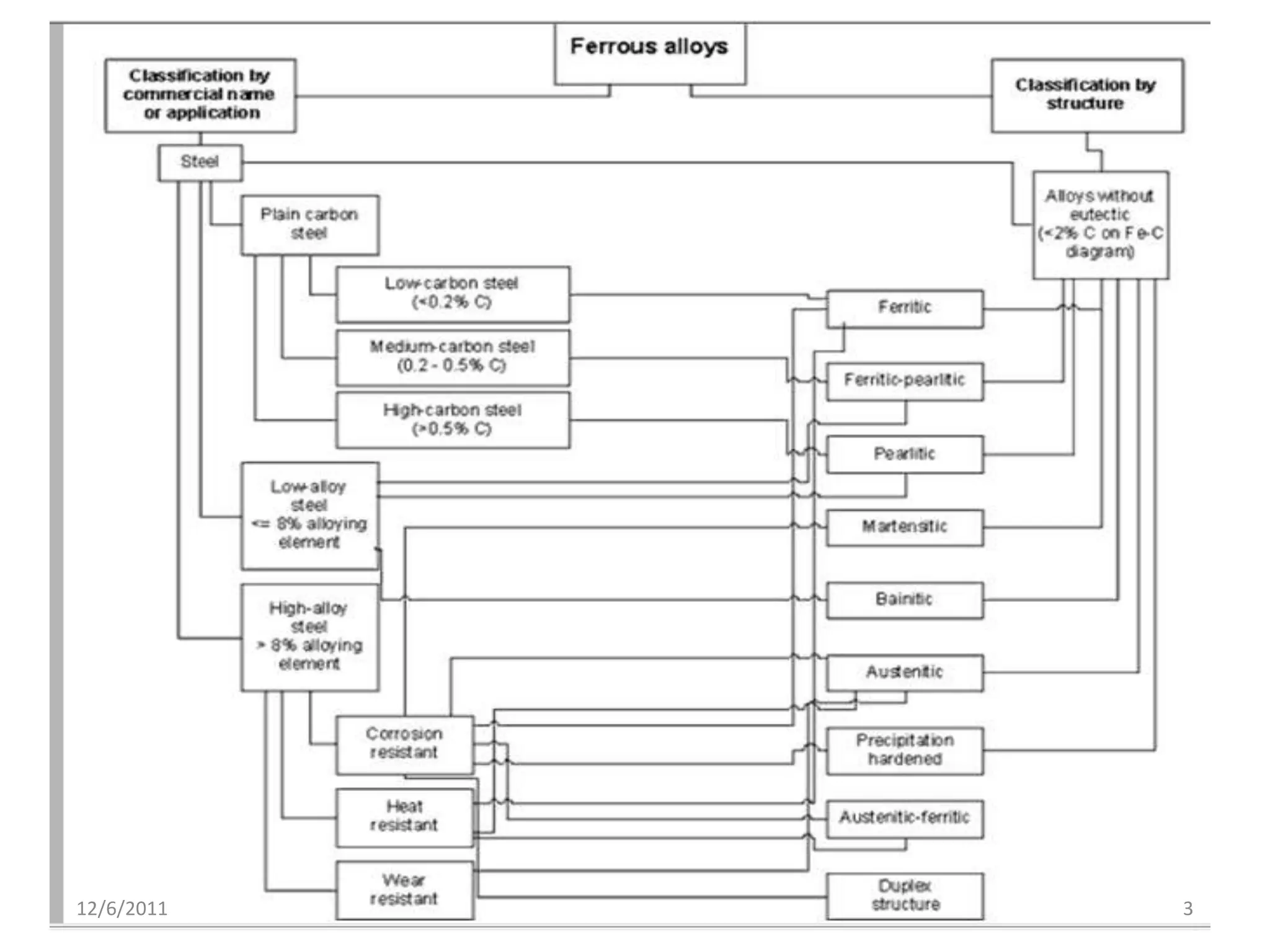

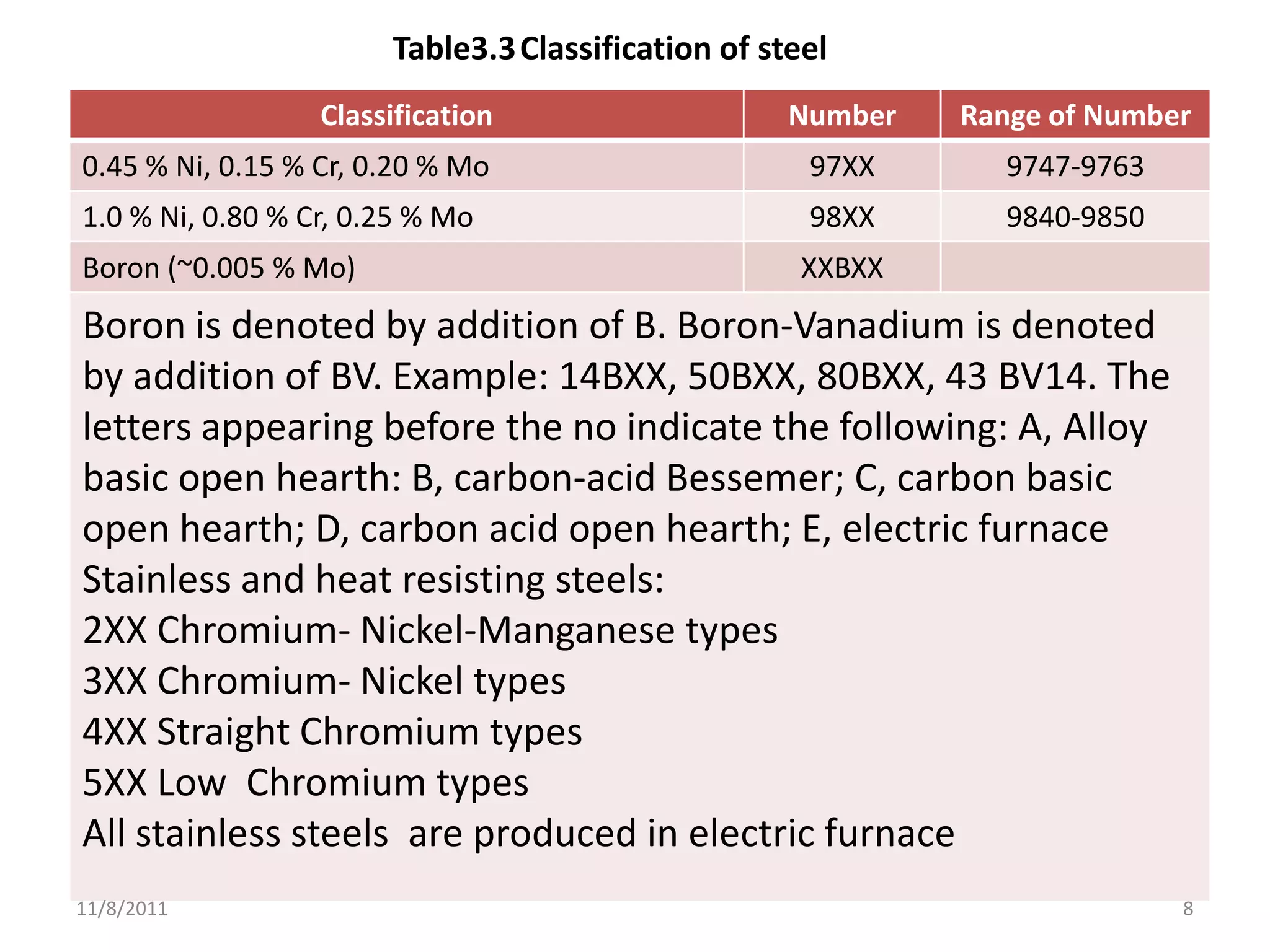

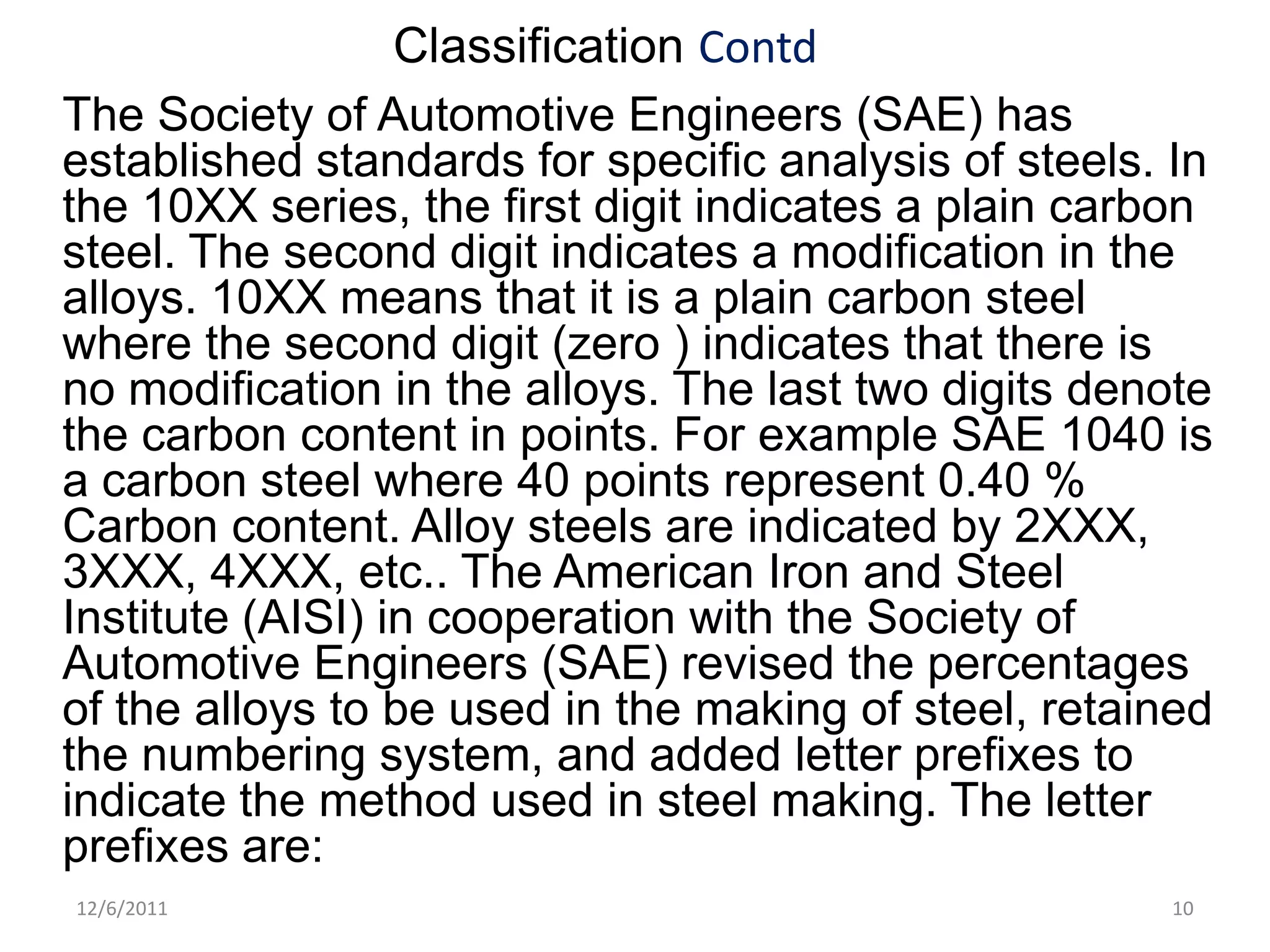

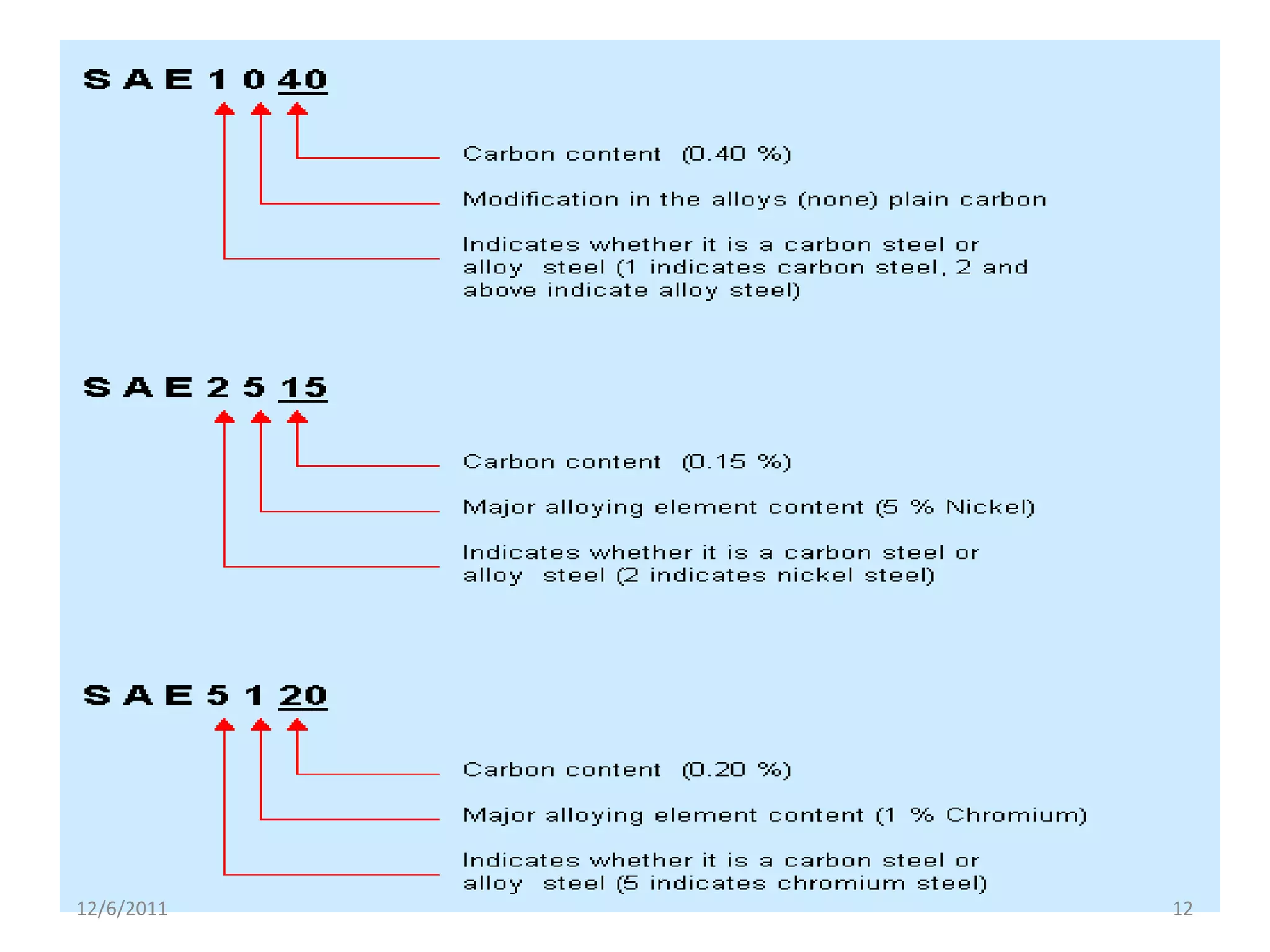

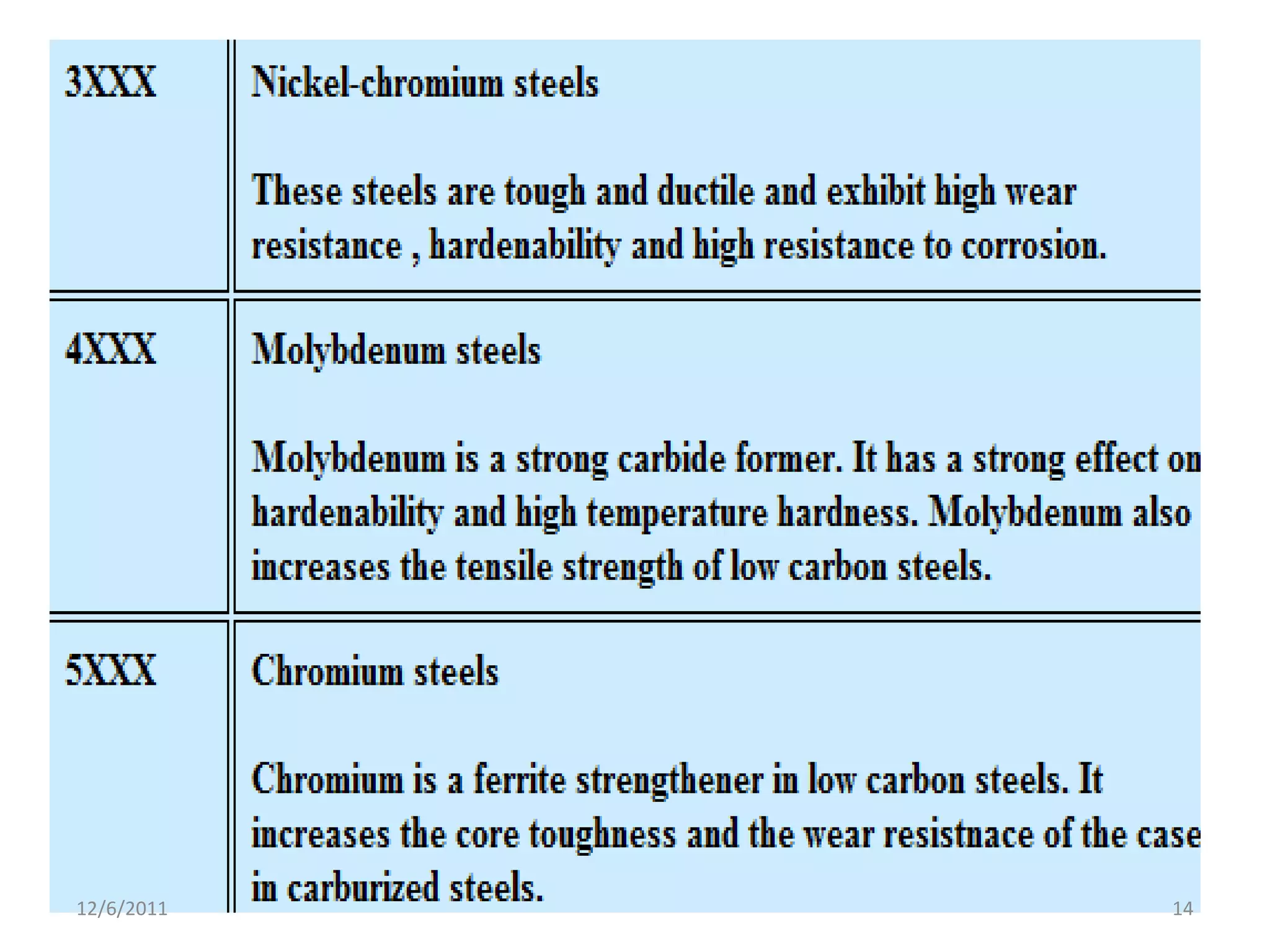

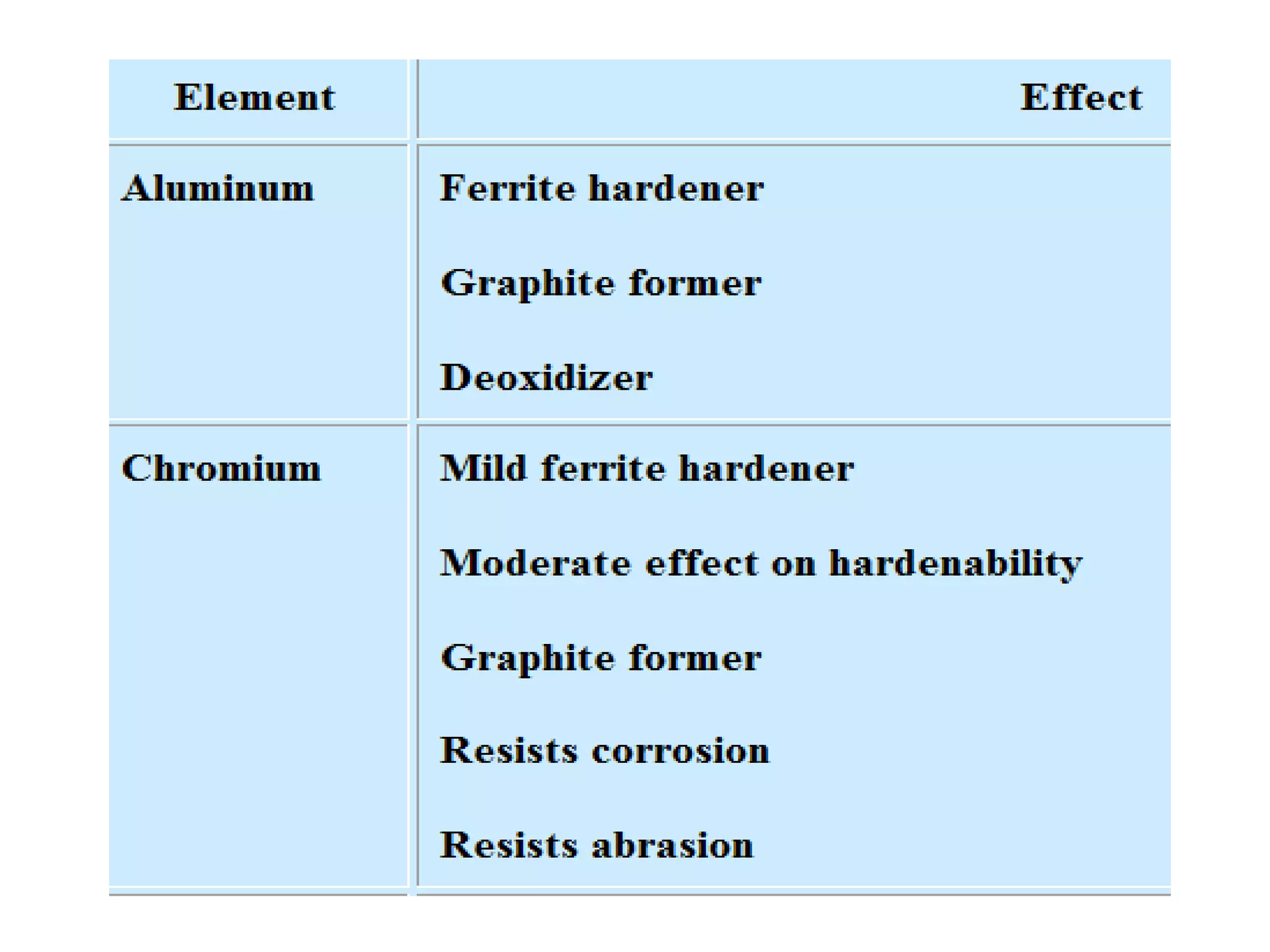

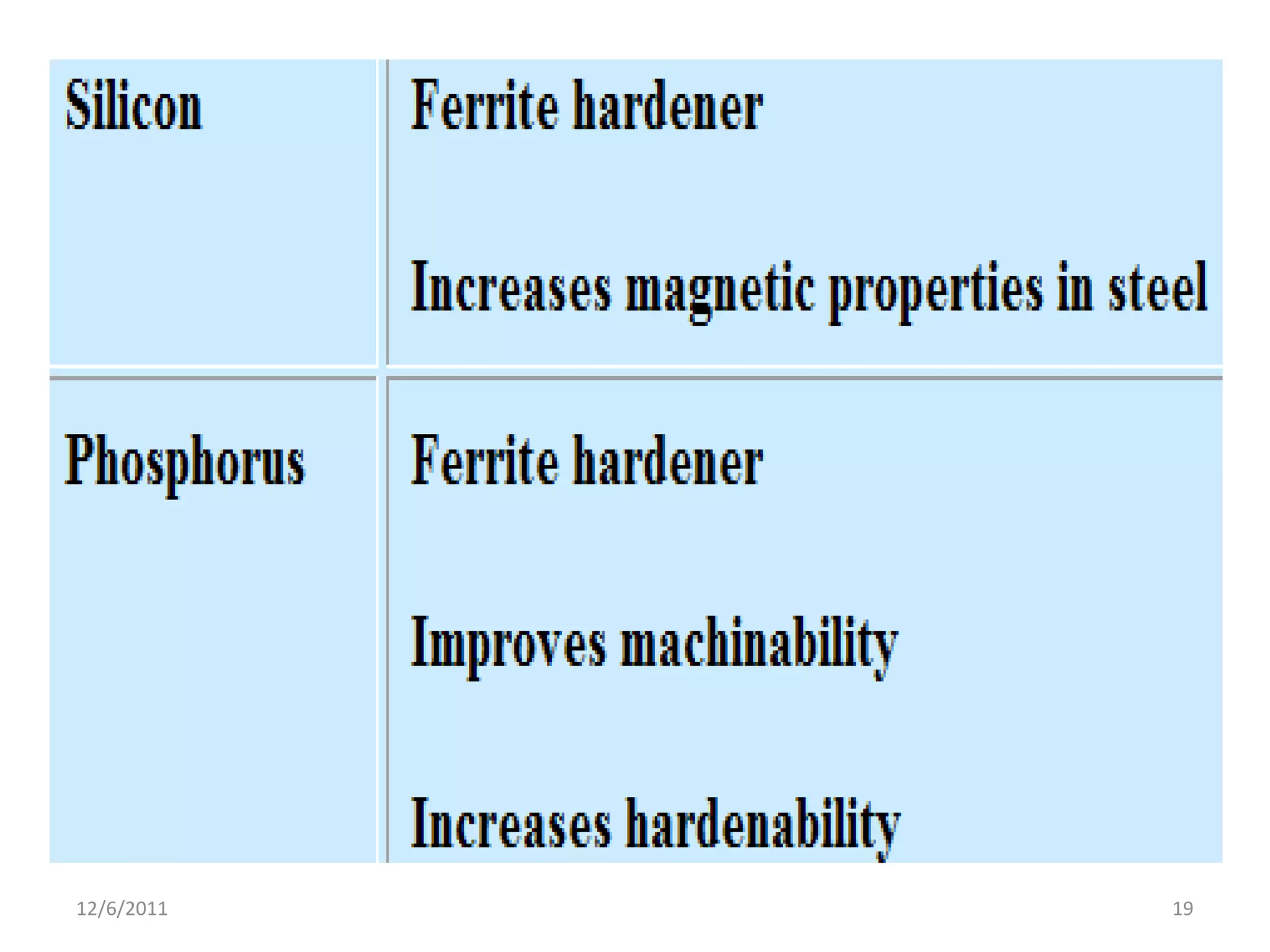

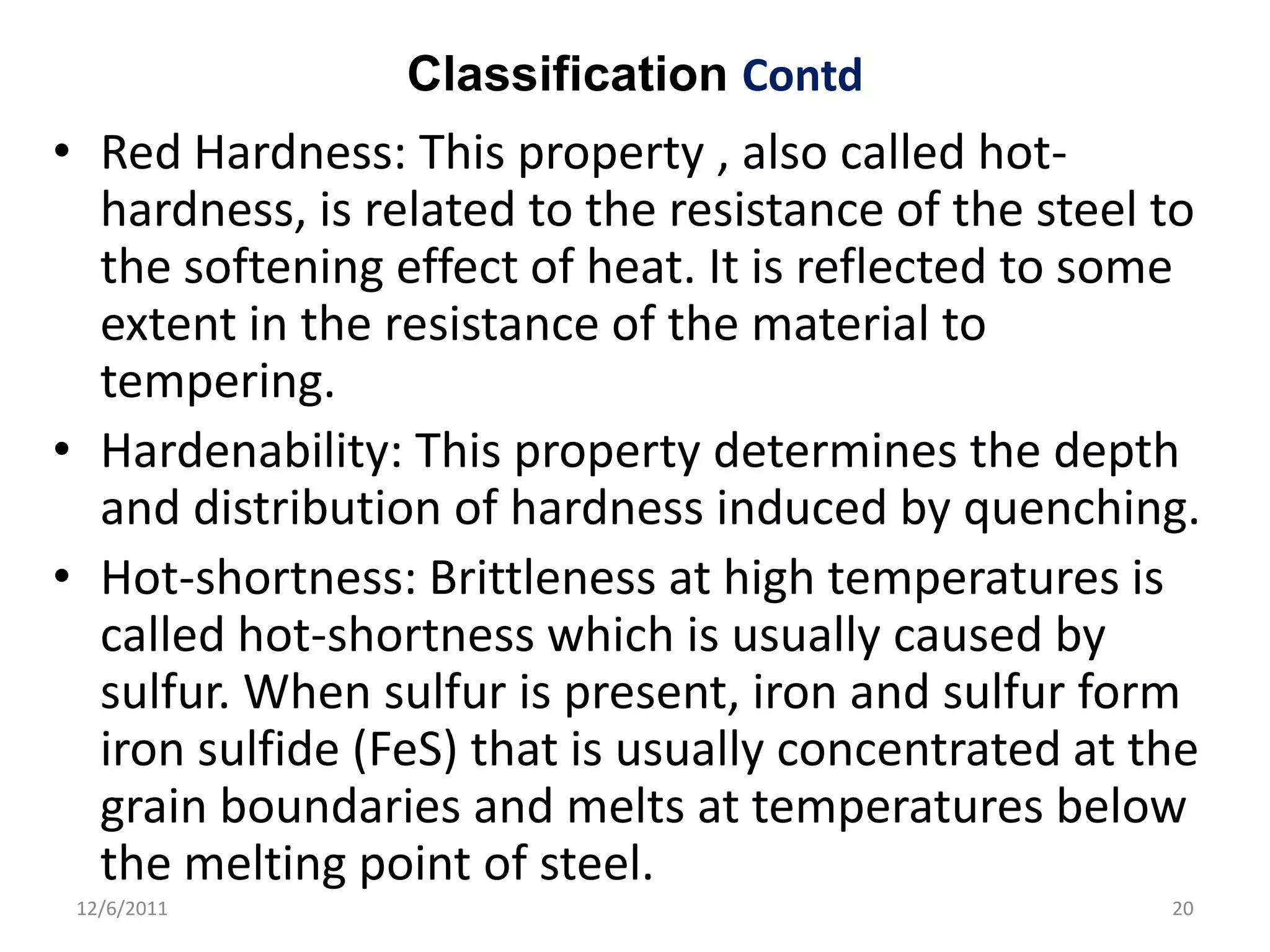

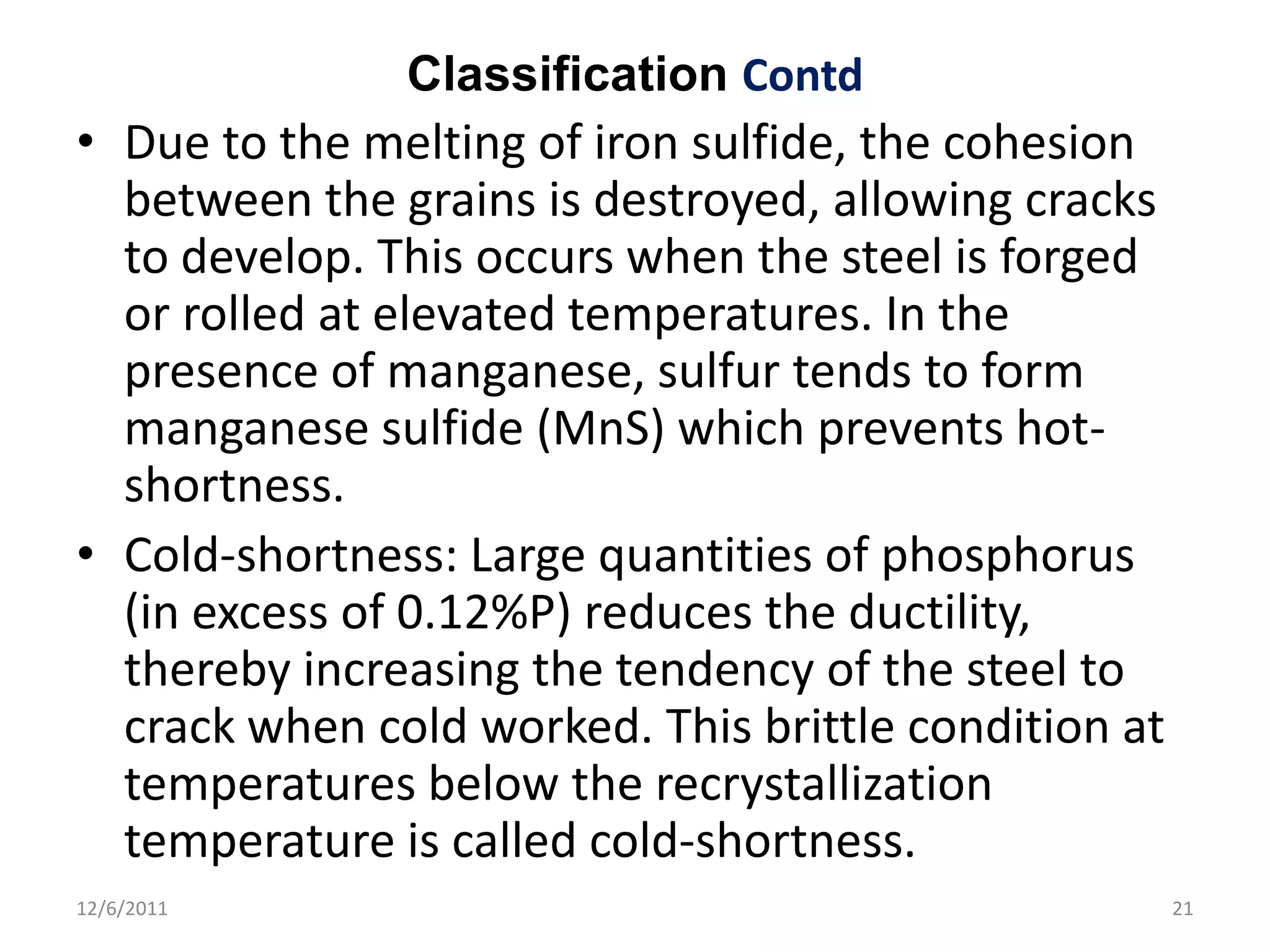

The document discusses various classification systems used for iron and steel based on composition, manufacturing method, product form, microstructure, required strength level, and other factors. It focuses on the classification of carbon steels and alloy steels according to standards set by organizations like ASTM, SAE, and AISI. Key classification aspects covered include carbon content, alloying elements, manufacturing processes, product types, and material properties.