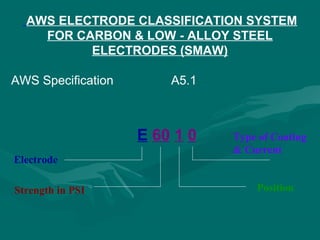

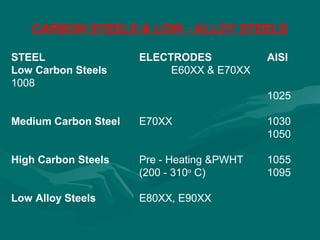

The document discusses different types of coatings and fluxes used for welding electrodes, including cellulose, rutile, ball clay and iron powder coatings, and explains that coatings provide gas shielding, stabilize the arc, produce slag, and improve weld properties. It also covers electrode classifications based on coating, application, and AWS standards, and discusses welding of carbon steels, low-alloy steels, and stainless steels.