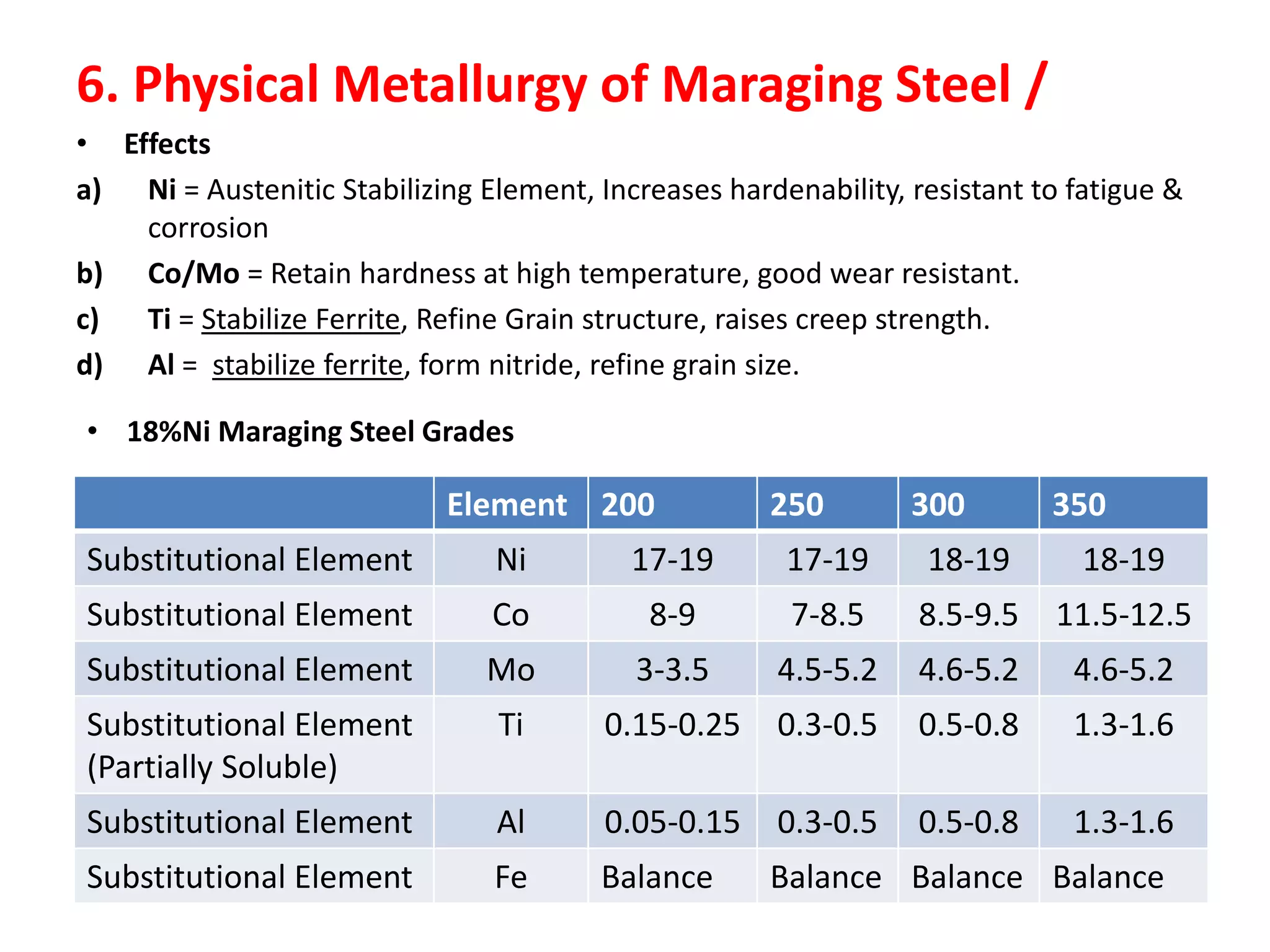

Maraging steels are carbon-free iron alloys that are strengthened through precipitation hardening rather than carbon content. They contain additions of nickel, cobalt, molybdenum, titanium, and aluminum. Maraging steels are heat treated through solution treatment to form a martensitic structure, followed by aging to precipitate hardening intermetallic compounds within the martensite. This provides maraging steels with ultra-high strength even at elevated temperatures, along with excellent toughness. Common applications include aerospace components, ordnance, and tooling due to their combination of high strength, corrosion resistance, and fatigue endurance.