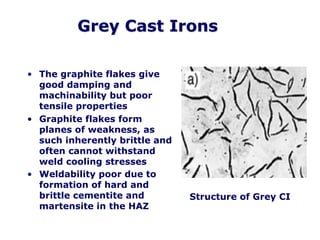

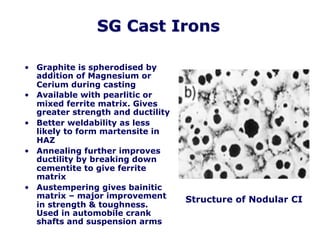

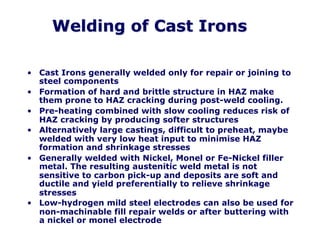

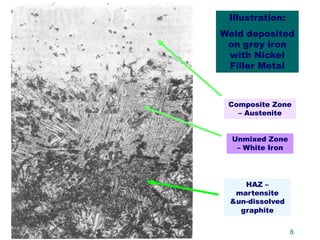

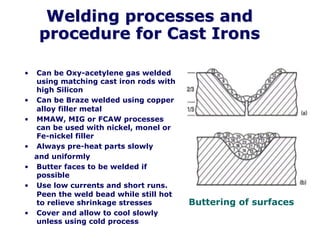

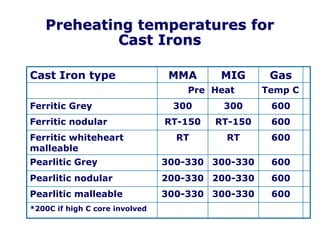

This document discusses welding of cast irons. It describes the different types of cast iron including grey, nodular, white, and malleable cast irons. Grey cast irons contain graphite flakes which provide good machinability but poor tensile properties and weldability due to formation of hard and brittle cementite and martensite in the heat affected zone. Nodular cast irons have spheroidal graphite and better weldability. When welding cast irons, preheating and slow cooling is recommended to reduce cracking due to hard phases forming in the HAZ. Nickel or iron-nickel filler metals are commonly used for their ductility. Low heat input welding techniques help minimize the hardening