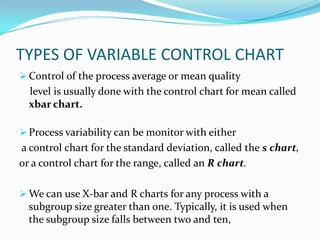

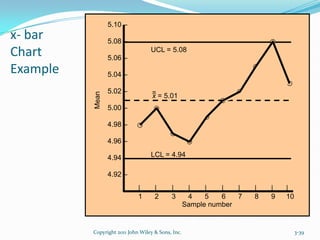

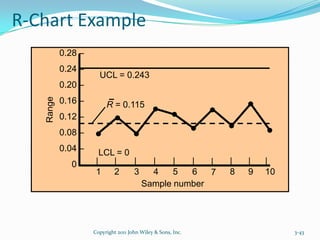

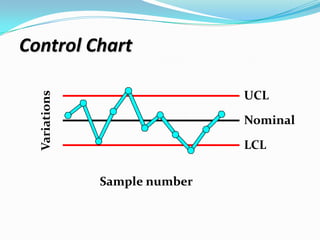

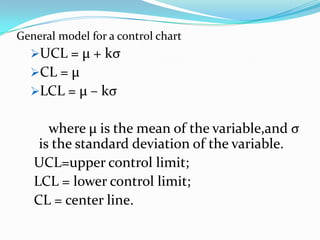

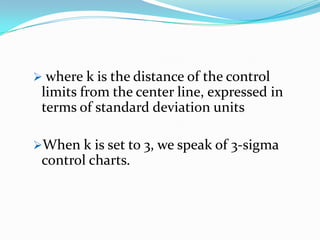

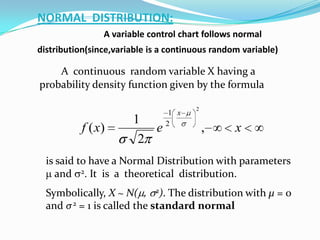

Statistical Quality Control (SQC) is used to evaluate organizational quality through statistical tools. SQC can be classified into descriptive statistics, statistical process control, and acceptance sampling. Descriptive statistics describe quality characteristics and relationships through measures like the mean and standard deviation. Statistical process control uses random sampling to determine if a process is producing products within a predetermined range. Acceptance sampling involves random inspection of samples to determine if an entire lot should be accepted or rejected. Control charts graphically show whether sample data falls within the normal variation limits.

![STANDARDIZING PROCESS

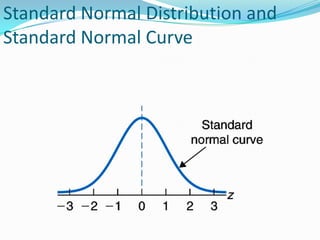

This can be done by means of the transformation.

The mean of Z is zero and the variance is respectively,

x

z

X

X Var( Z ) Var

E (Z ) E

1

2

Var( X )

1

E X

1

2

Var( X )

1

[E( X ) ] 1 2

2

0

1](https://image.slidesharecdn.com/statisticalqualitycontrol2-120903115417-phpapp02/85/Statistical-quality__control_2-24-320.jpg)