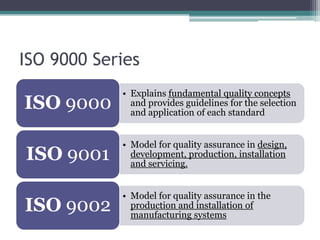

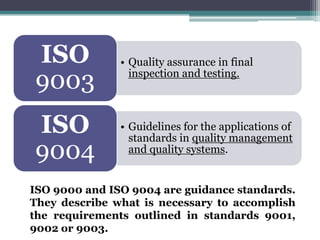

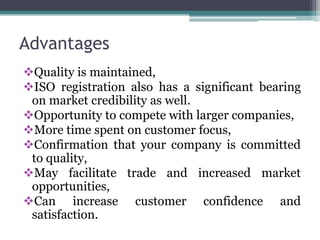

ISO 9000 is a family of standards related to quality management systems and procedures. It helps organizations ensure they meet customer and stakeholder needs while complying with legal requirements. The standards are based on eight quality management principles including customer focus, leadership, and continual improvement. ISO 9000 deals with quality management fundamentals, while ISO 9001 provides requirements for quality assurance in design and manufacturing. Implementing an ISO-certified quality management system helps organizations improve quality, meet regulations, and increase market credibility.