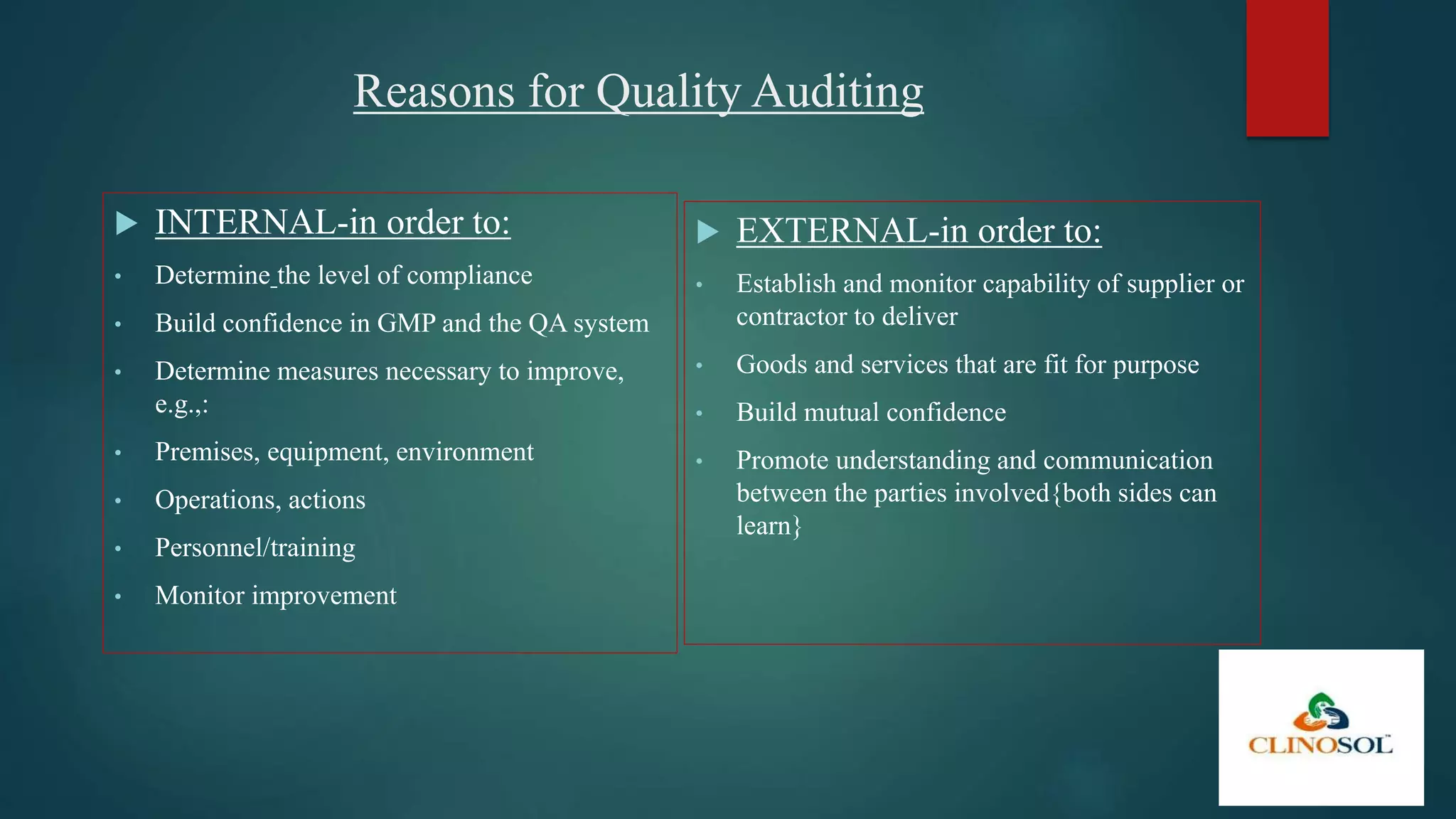

A quality audit is an independent examination to assess compliance with quality standards and effectiveness in achieving objectives, typically conducted at defined intervals. It serves to ensure product quality, improve QA systems, and build interdepartmental trust. Audits can be internal or external, are vital for regulatory compliance, and help identify potential problems and necessary improvements in manufacturing processes.

![Who performs an Audit?

[A] Imposed upon

manufacturer or

supplier

[B] Performed by

manufacturer

Regulatory

Customer or

Potential customer

Third party

Internal{Self-

Inspection}

External

• Overall

• Departmental

• Product-based

• System-oriented

• Supplier

• Contract manufacturer

• Packager](https://image.slidesharecdn.com/14-230523094458-4fa05be0/75/Quality-Audit-13-2048.jpg)