This document discusses various aspects of quality control including:

1. It defines quality as the degree to which a product meets customer needs based on factors like design, production, and inspection.

2. It describes types of inspection as preventive (finding defects before production) and corrective (finding defects after production).

3. It defines quality control as processes used to ensure uniform, acceptable product quality and analytical quality control as procedures to ensure consistent, accurate lab test results.

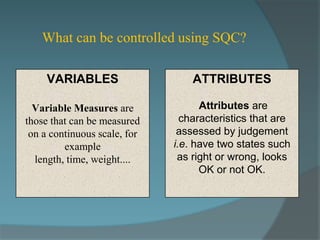

4. It discusses statistical quality control using parameters and statistics to analyze process variations, good manufacturing practices to ensure quality products, and quality assurance to implement quality system activities so requirements are fulfilled.