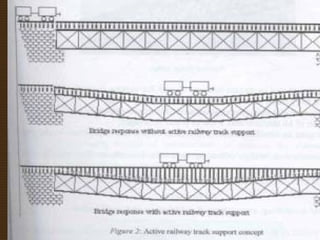

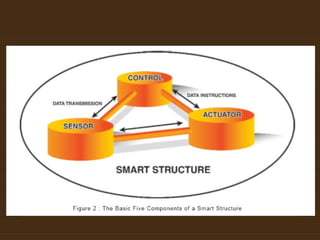

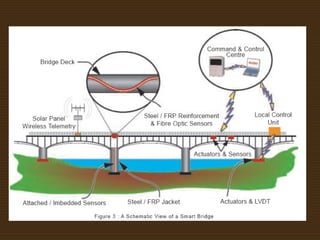

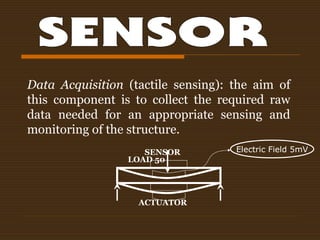

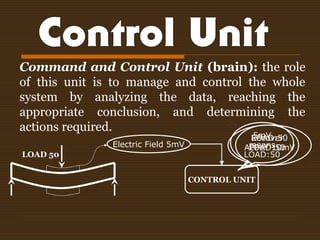

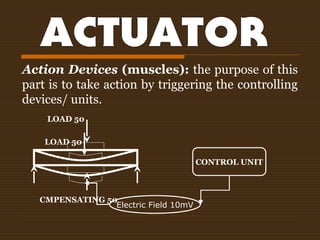

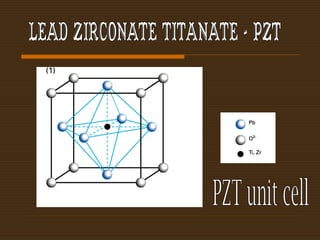

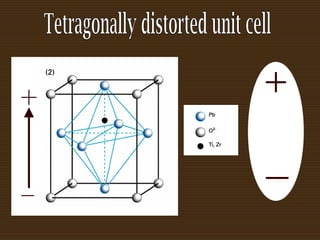

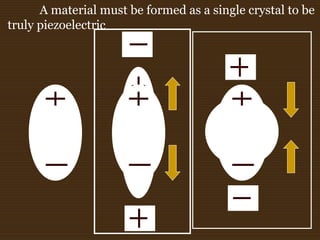

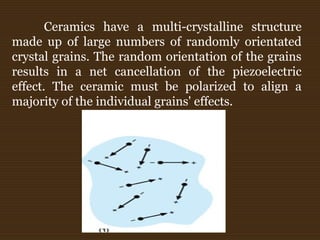

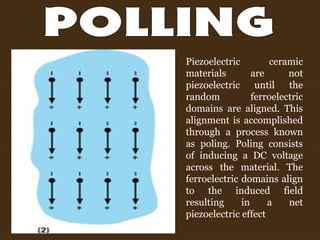

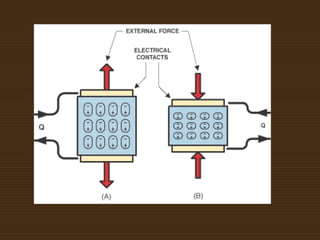

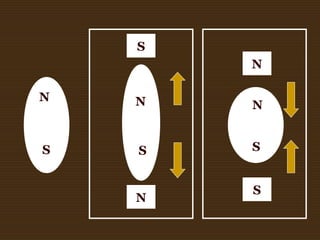

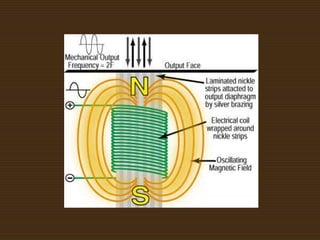

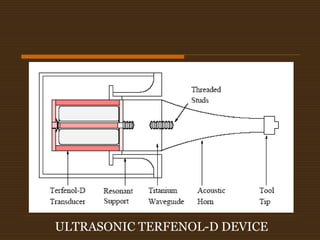

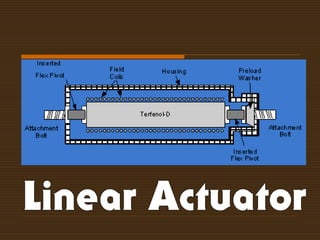

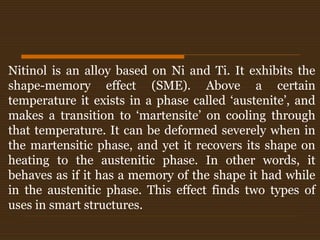

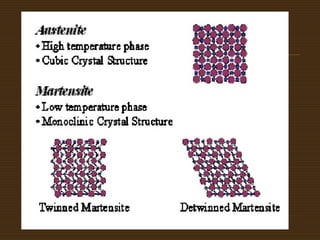

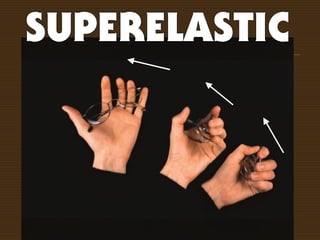

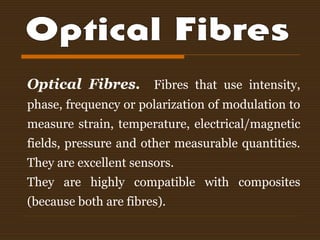

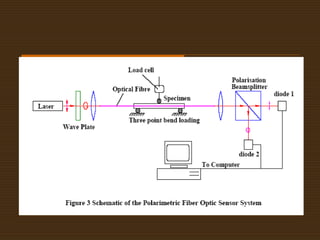

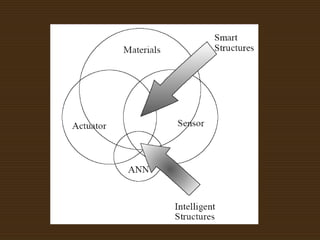

The document discusses smart structures that integrate sensors and actuators to interact with their environment in adaptive ways. It describes various smart materials, such as piezoelectric and shape memory alloys, that respond to environmental stimuli and the importance of material properties, like crystal structure, for their functions. Additionally, it highlights the potential applications of these technologies in improving material efficiency and the development of intelligent structures with learning capabilities.