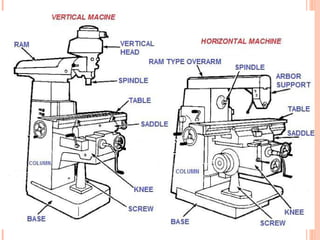

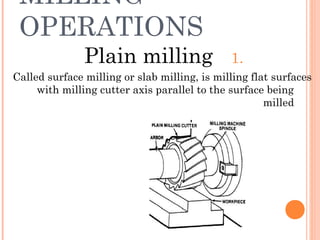

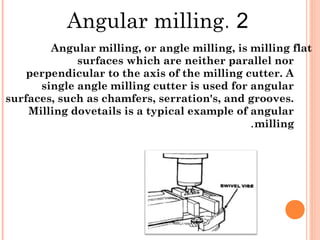

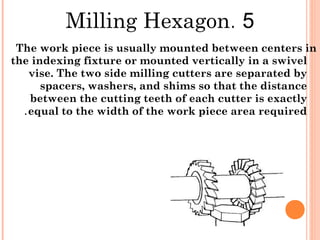

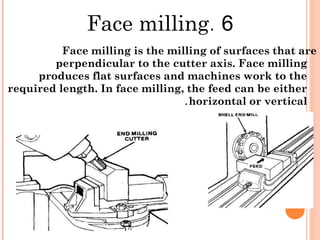

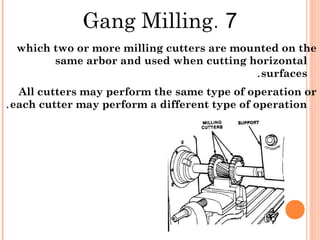

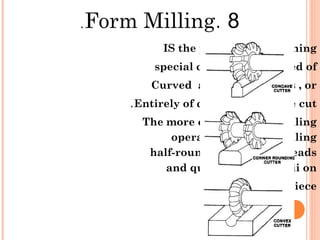

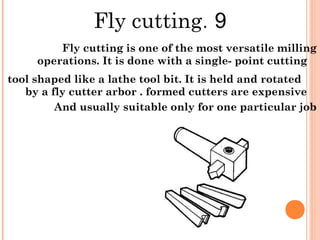

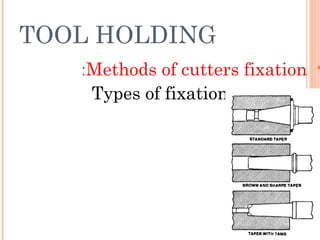

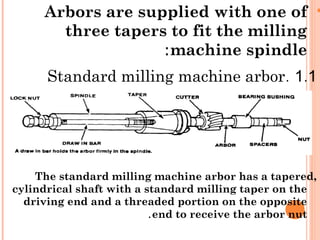

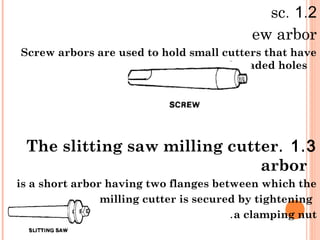

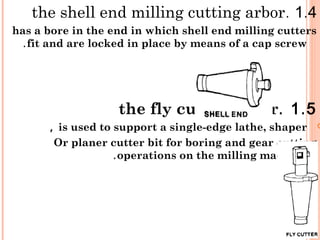

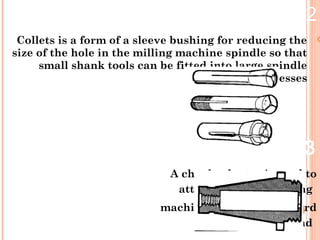

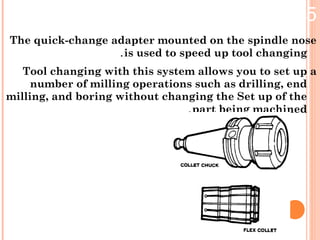

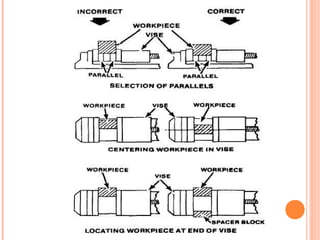

Milling machines perform machining operations through rotating cutters that remove material from the workpiece. There are several types of milling machines including vertical, horizontal, and universal milling machines. Milling operations include plain milling for flat surfaces, angular milling for chamfers and grooves, straddle milling for parallel surfaces, face milling for perpendicular surfaces, and form milling for complex contours. Cutters are held using various arbors, collets, chucks, and adapters. Workpieces are mounted to the machine table, angle plate, fixtures, between centers, in a chuck, or vise depending on the operation.