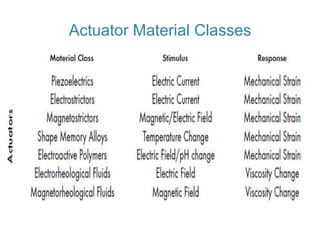

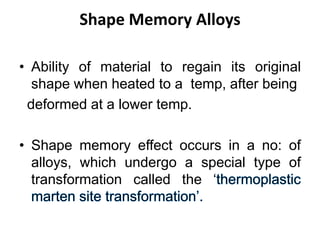

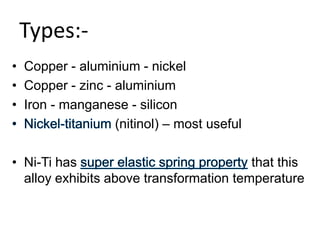

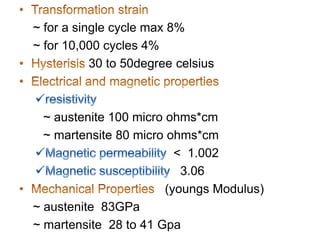

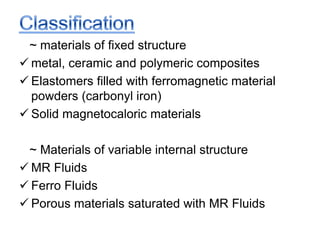

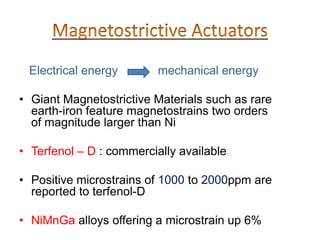

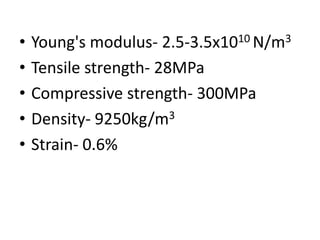

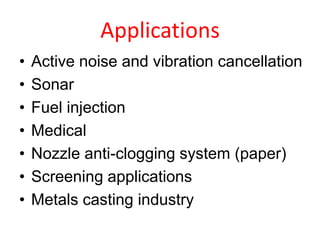

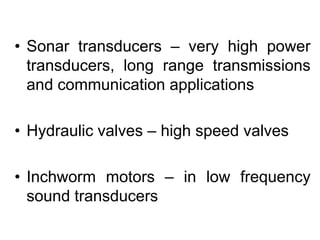

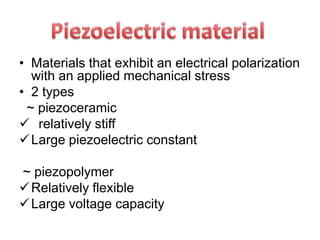

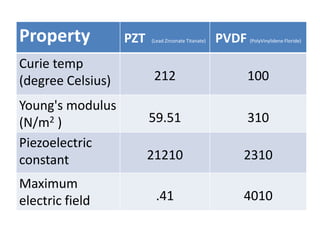

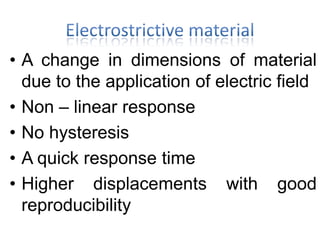

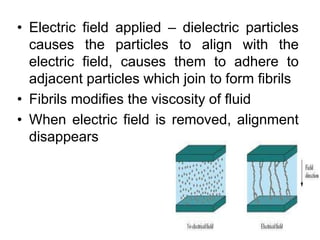

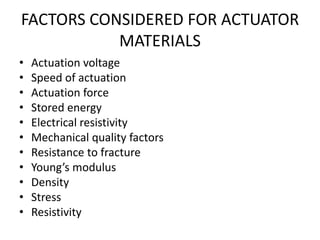

This document discusses different types of actuator materials including shape memory alloys, magnetostrictive materials, piezoelectric materials, and electrorheological fluids. Shape memory alloys can change shape, stiffness, position, natural frequency, and other mechanical characteristics in response to temperature or electromagnetic fields. Magnetostrictive materials like terfenol-d change shape in response to magnetic fields. Piezoelectric materials like PZT and PVDF are capable of generating an electric charge when subjected to mechanical stress. Electrorheological fluids can rapidly change viscosity and alter flow properties when an electric field is applied. Key factors for selecting actuator materials include actuation voltage/speed, force, stored energy, resistivity, mechanical properties