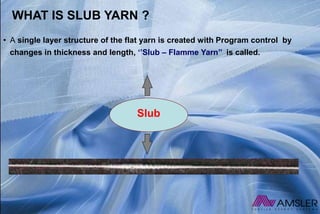

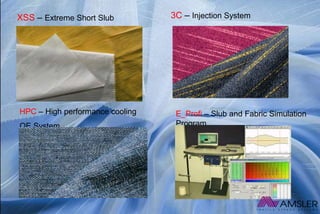

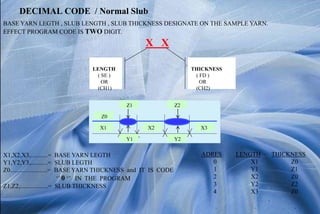

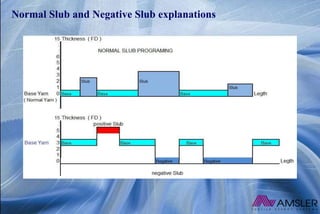

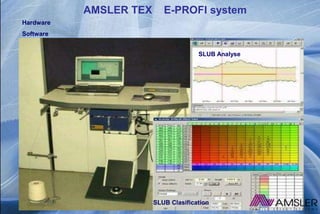

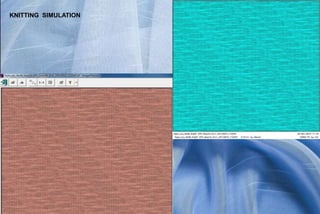

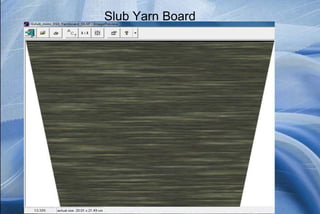

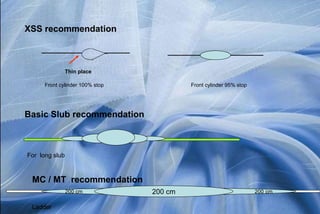

This document provides information about fancy yarns from Amsler Tex. It defines fancy yarn as having varied characteristics like thickness, color, and raw material that give fabrics a unique aesthetic. It then lists and describes different types of fancy yarns that can be produced using Amsler devices, including slub yarn, multi-count yarn, and multi-twist yarn. The document also explains concepts like the working principles of drafting and twisting systems, yarn measurement, effect coding, and how to simulate fabrics digitally before production.