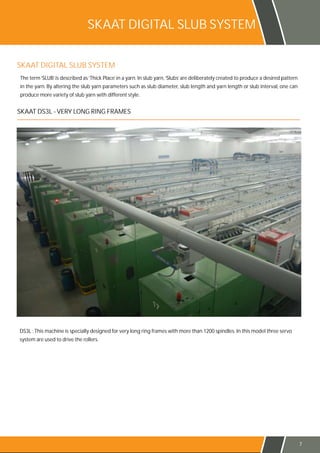

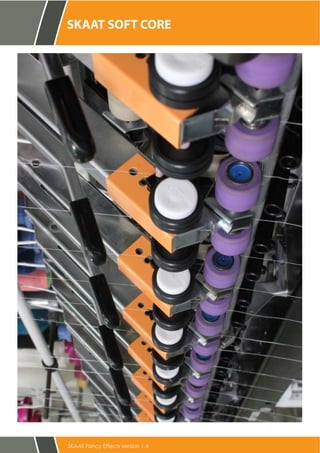

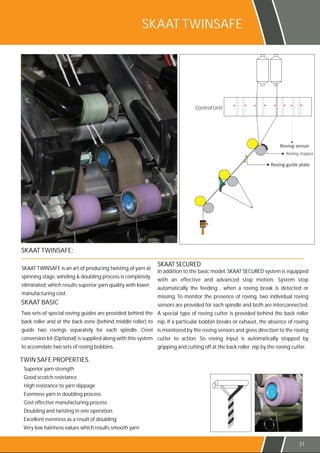

This document provides information on various slub and fancy yarn production systems from SKAAT. It describes the SKAAT Digital Slub System for controlling slub parameters like diameter, length and interval. It also outlines models for very long ring frames, multi-effect yarns, core yarns including soft, rigid and twin core, roving injection, twin safe systems, rainbow yarn with multiple colors, and a slub tester to analyze yarn properties. The systems aim to produce different slub and fancy yarn styles through control of drafting and roller movements.