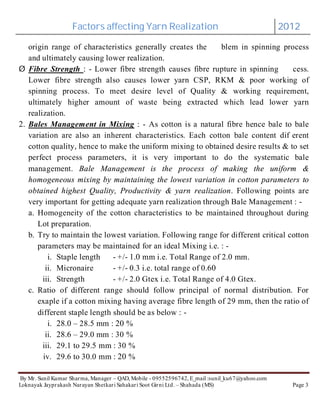

The document discusses the key factors affecting cotton yarn realization, which is crucial for the performance and profitability of spinning mills. Important factors include cotton characteristics, bale management, atmospheric conditions, process parameters, count patterns, end-use quality requirements, and moisture management. The author's insights derive from 20 years of practical experience in the spinning field, emphasizing the need for careful handling and quality control to optimize yarn production.