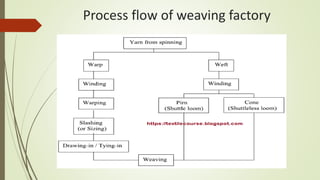

This presentation provides an overview of the weaving factory process from winding yarn to the final woven fabric. It discusses the major steps of winding, warping, sizing, weaving and the different types of looms and processes within each step. Safety and health risks are also summarized such as risks of falls, machinery, noise and fibre dust. Wastages at each stage are outlined including from winding defects, warping remains, sizing trial runs and weaving defects. The presentation aims to give an understanding of the full production cycle at a weaving mill.