The document provides an overview of Six Sigma, including:

- Six Sigma aims to reduce defects and variation in processes by focusing on outputs that are within 6 standard deviations from the mean.

- It was introduced at Motorola in 1986 and uses statistical tools and a DMAIC methodology for continuous improvement.

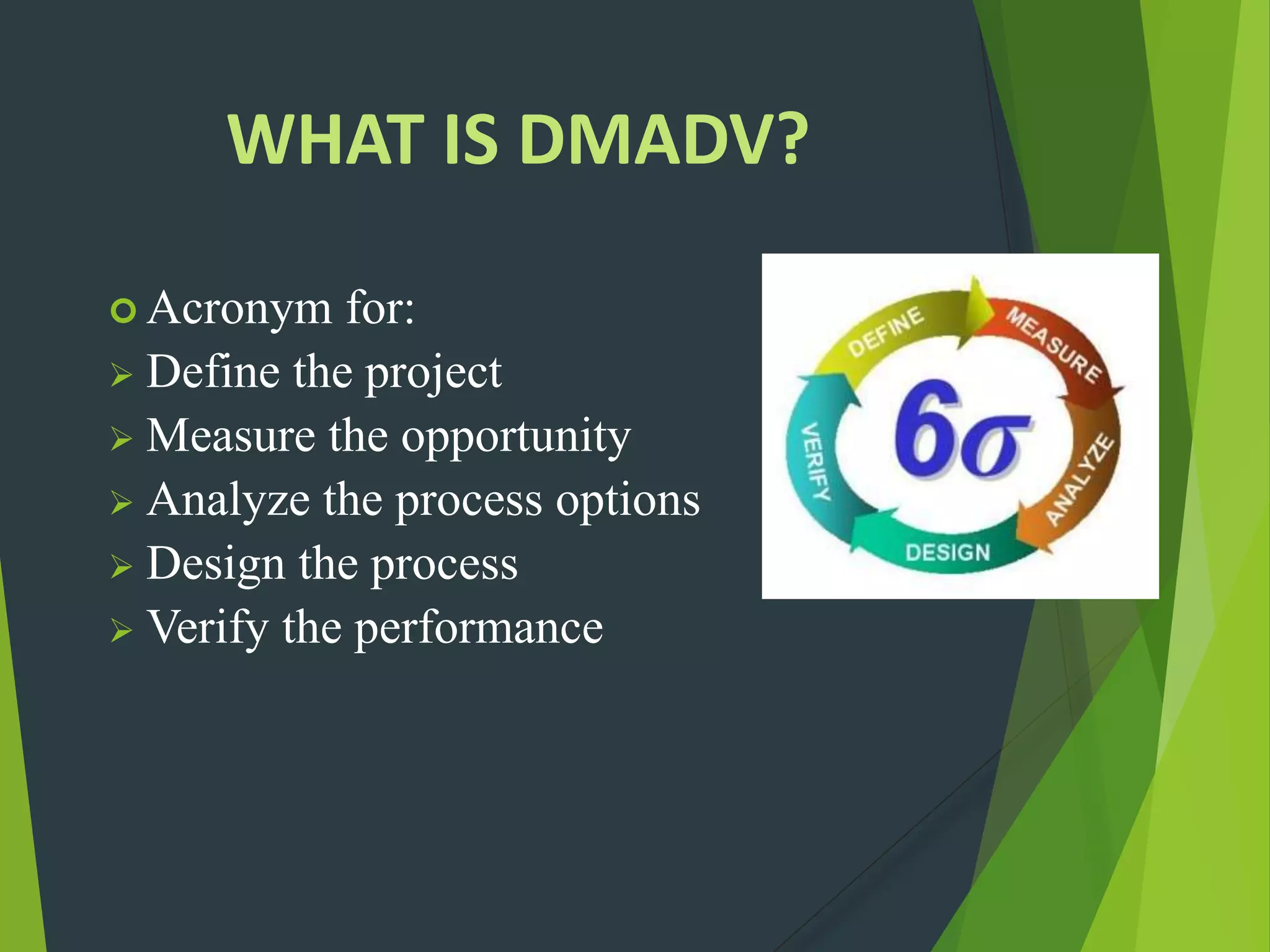

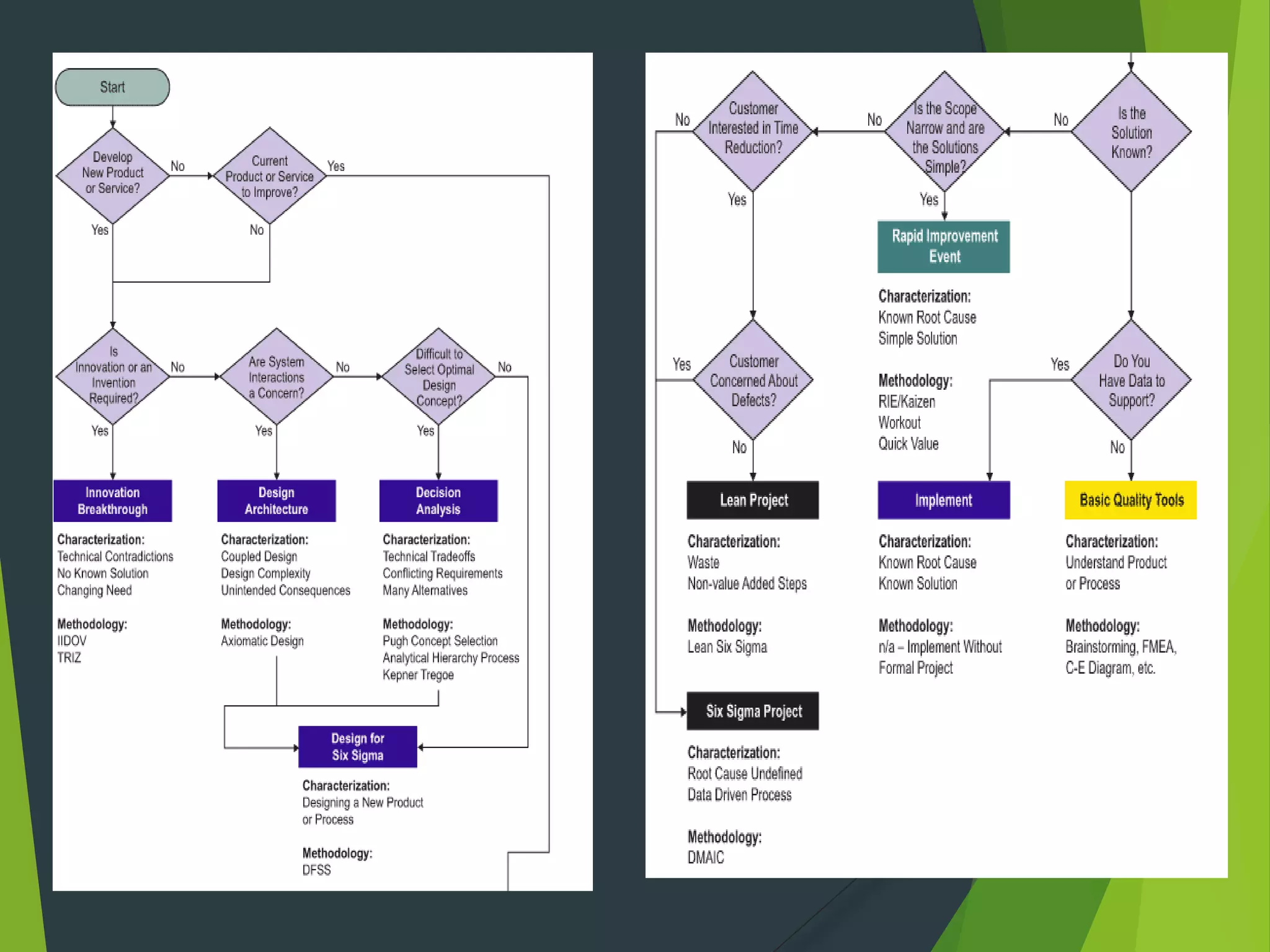

- DMAIC stands for Define, Measure, Analyze, Improve, Control and is an iterative problem-solving approach. DMADV is for creating new processes.

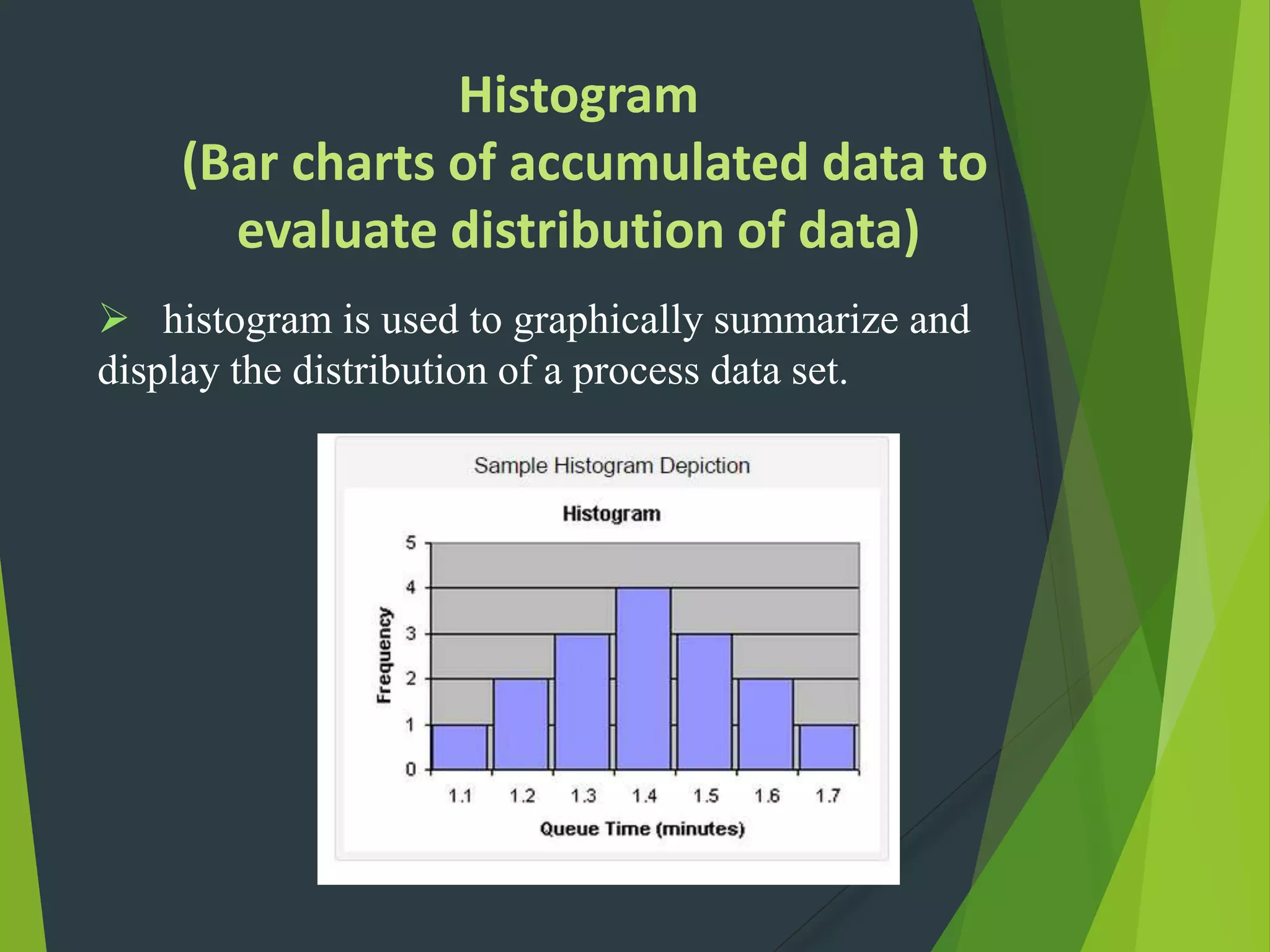

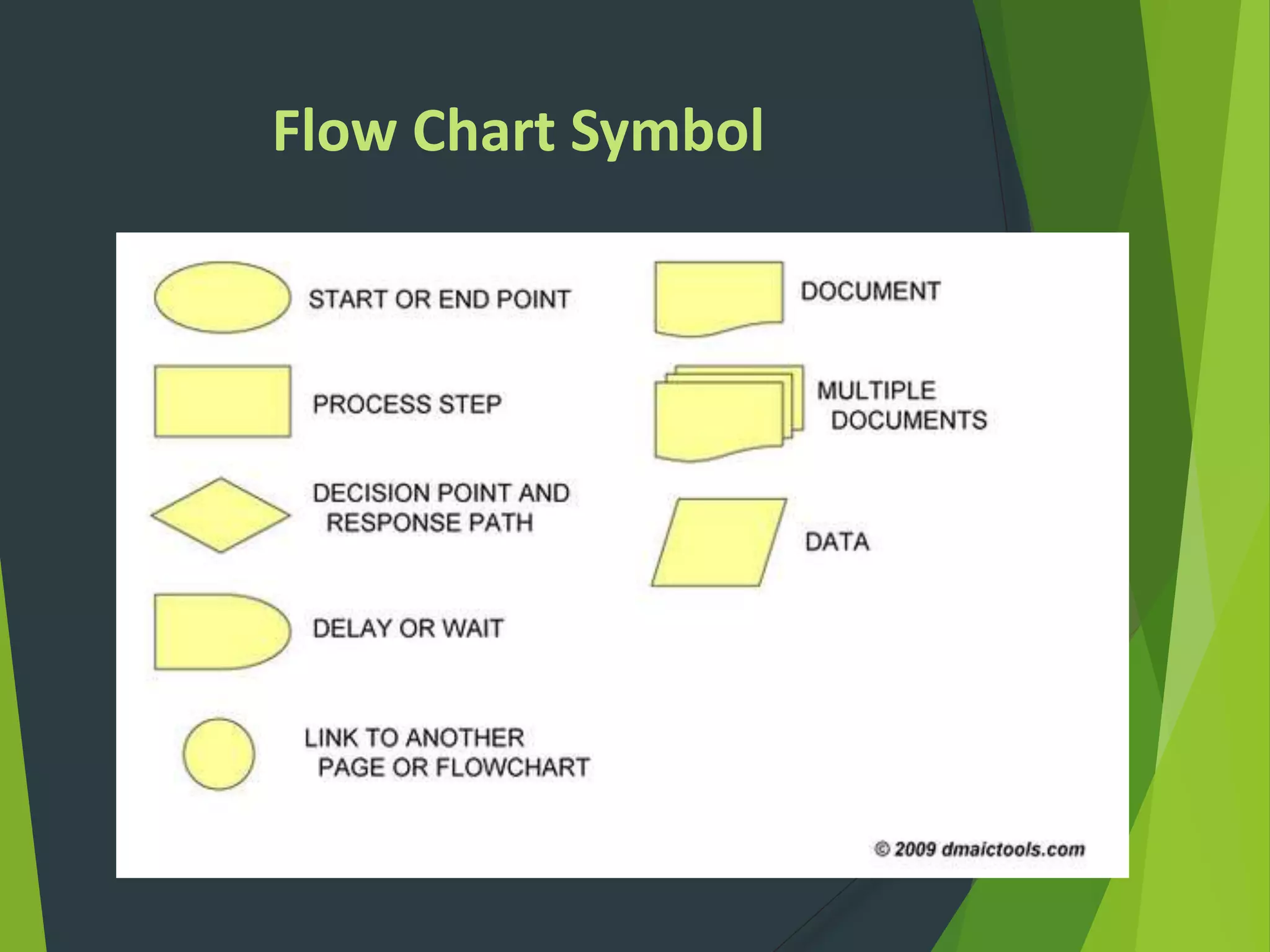

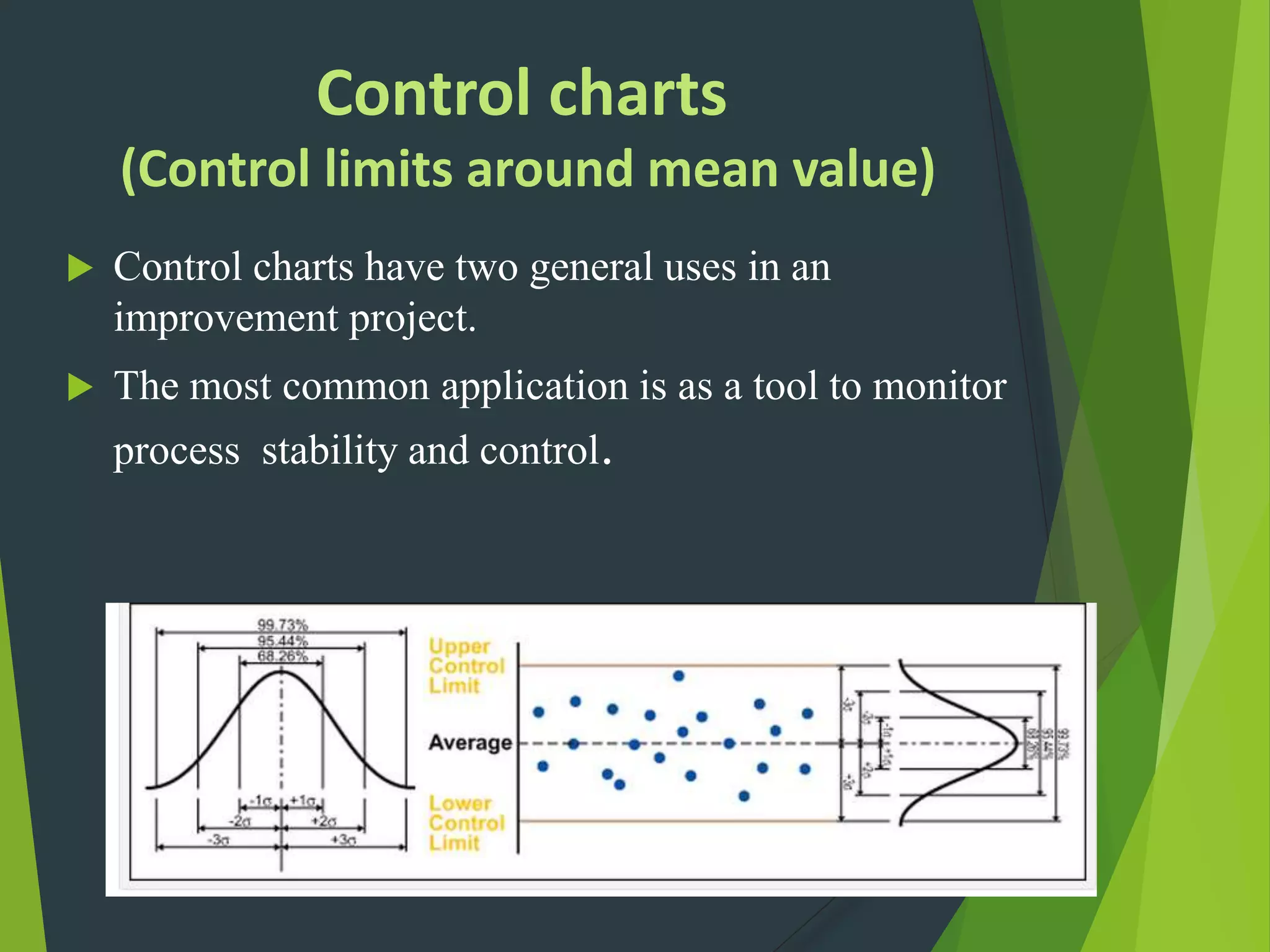

- Key Six Sigma roles include Champions, Master Black Belts, Black Belts and Green Belts. A variety of statistical tools can be used including flow charts, histograms, control charts and Pareto charts.