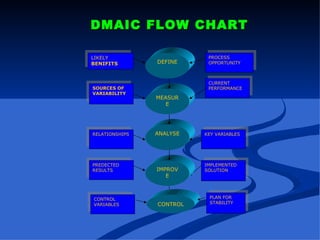

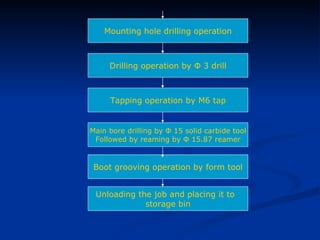

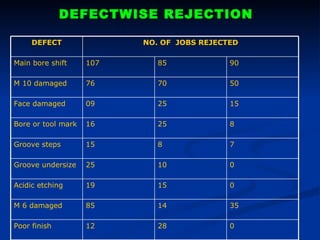

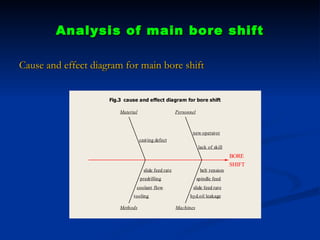

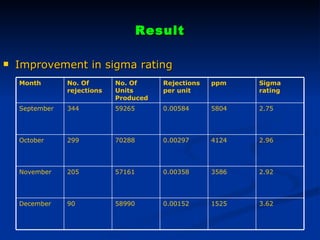

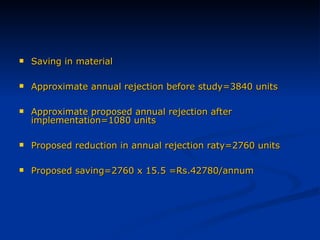

The document discusses using Six Sigma methodology to reduce in-process rejections at a manufacturing unit producing wheel cylinders. It analyzes the main causes of rejection, implements solutions, and measures the results. The key defects causing rejection were identified as main bore shift and M10 damage. Solutions like correcting hydraulic leaks, improving clamping, and modifying casting processes reduced monthly rejections from 205 to 15 and increased the sigma rating from 2.92 to 3.62, saving approximately $42,780 annually.