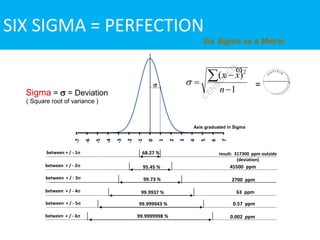

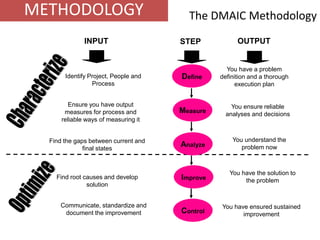

This document discusses Six Sigma, which aims to reduce variability in business processes. It defines Six Sigma as a statistical term representing 3.4 defects per million opportunities. The document outlines the benefits of Six Sigma, such as generating sustained success, enhancing customer value, and accelerating improvement. It also describes the DMAIC methodology, which is a five-step approach for process improvement involving Define, Measure, Analyze, Improve, and Control phases.