This document discusses different types of grinding machines and grinding processes. It begins with an introduction to grinding and then covers:

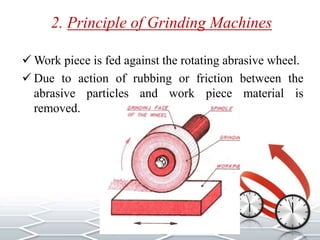

1. The principle of grinding involves abrasive particles on a rotating wheel removing material from the workpiece.

2. Types of grinding include rough and precision grinding. Classification of grinding machines includes bench, surface, cylindrical, centerless, internal, and special purpose grinding machines.

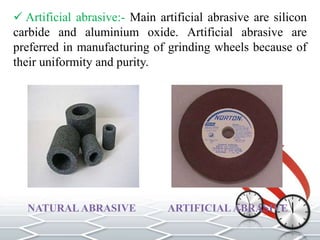

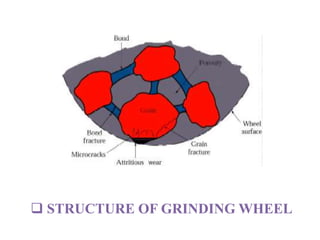

3. The various elements of a grinding wheel such as abrasives, bonds, and structure are described. Wheel shapes, coding systems, and methods for dressing grinding wheels are also outlined.