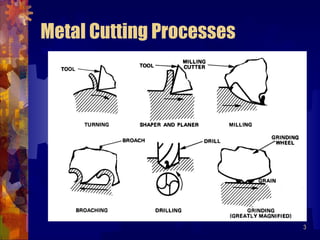

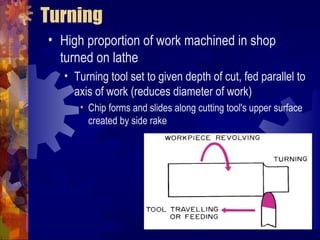

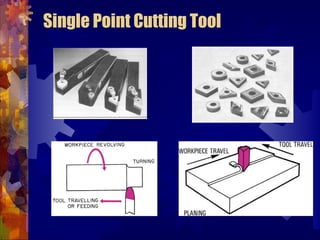

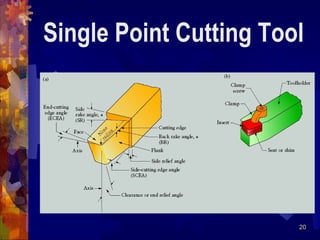

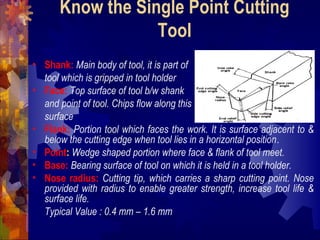

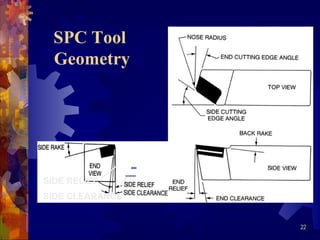

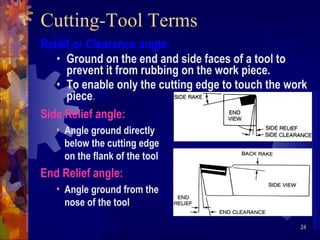

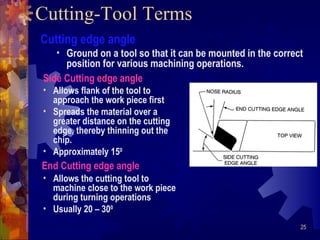

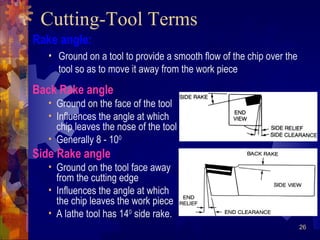

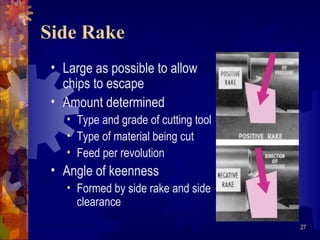

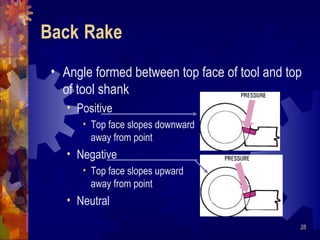

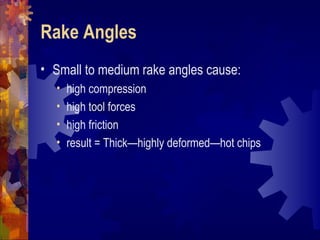

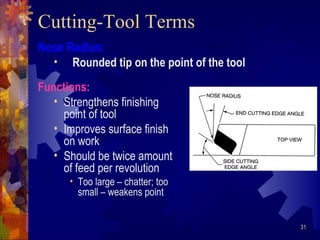

The document discusses cutting tools used in machining processes. It defines single point and multi-point cutting tools. Key terms related to cutting tool geometry are defined, including relief angle, rake angle, nose radius, and their purposes. Common cutting tool materials like high-speed steel and cemented carbides are also mentioned. The document provides information on selecting cutting tool geometry and materials based on factors like the workpiece material and type of machining operation.