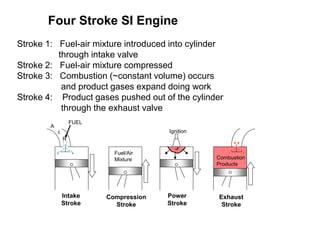

The four stroke SI engine involves four strokes - intake, compression, combustion, and exhaust. In the intake stroke, a fuel-air mixture is introduced into the cylinder through the intake valve. In the compression stroke, the fuel-air mixture is compressed. In the combustion stroke, combustion occurs at constant volume, causing the product gases to expand and do work. In the exhaust stroke, the product gases are pushed out through the exhaust valve.