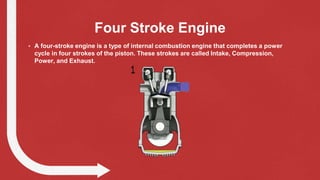

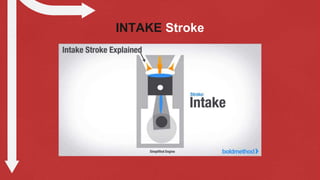

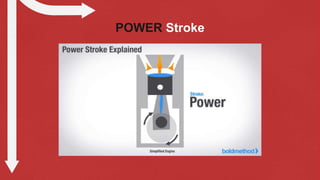

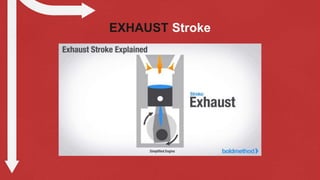

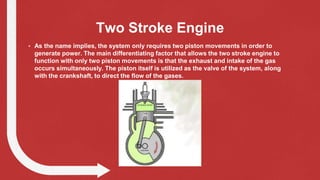

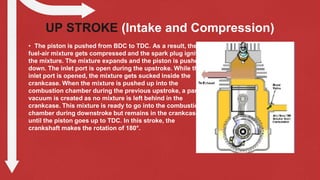

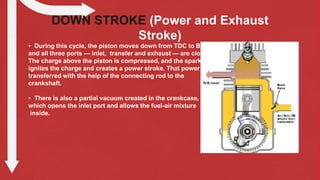

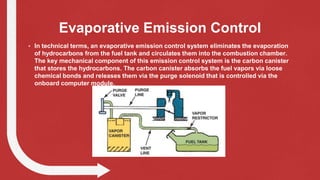

The document discusses internal combustion engines and their operation. It defines internal combustion engines as engines that convert chemical energy from fuel into mechanical energy through combustion inside a chamber. There are two main types - spark ignition engines that use gasoline and compression ignition engines, like diesel engines, that ignite fuel through compression. The document then describes the four stroke engine cycle and two stroke engine cycle in detail, explaining the intake, compression, power and exhaust strokes. It also discusses emission control systems like catalytic converters that reduce emissions and different engine components involved in emission control.