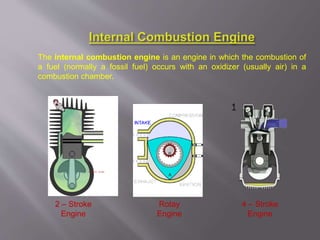

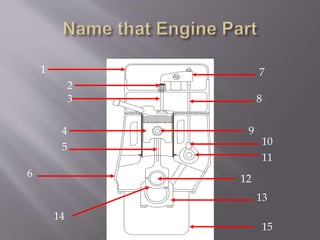

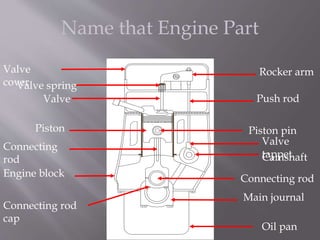

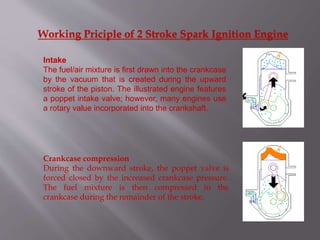

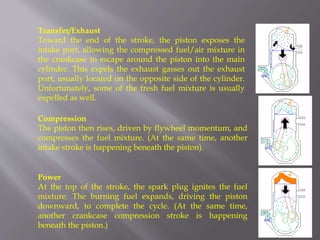

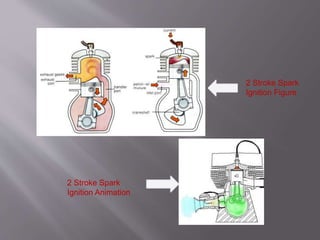

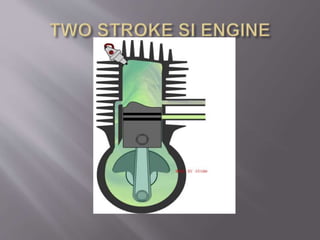

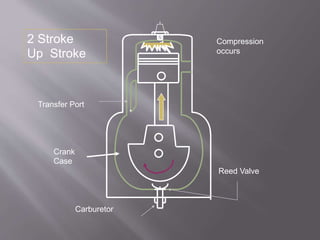

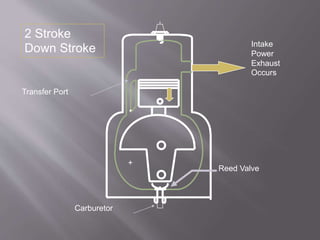

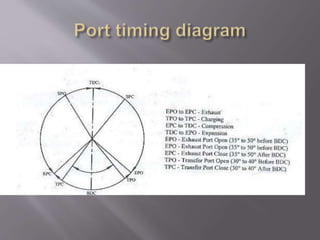

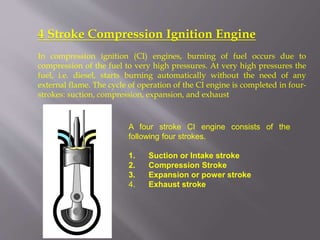

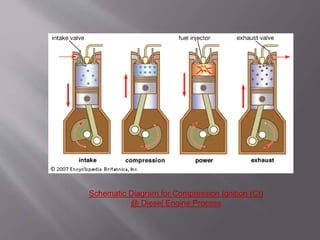

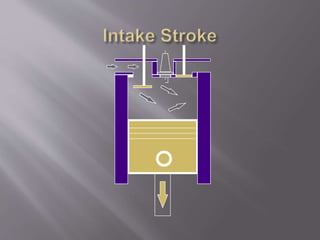

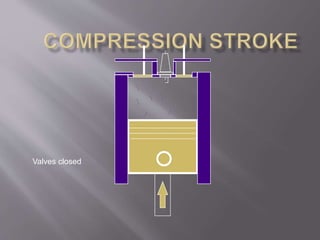

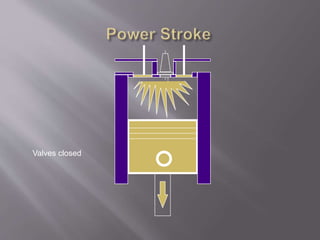

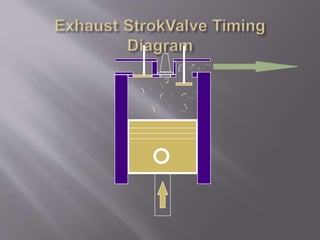

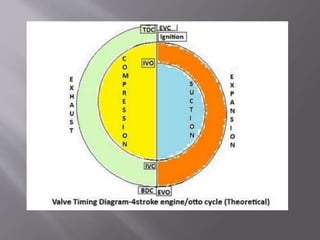

The document discusses internal combustion engines, including their basic components and operating cycles. It describes the four main strokes of a four-stroke engine: intake, compression, power, and exhaust. It also summarizes the operation of two-stroke engines and differences from four-stroke engines, such as using crankcase compression and ports instead of valves. Additionally, it covers the classification of engines as spark ignition or compression ignition and compares their combustion processes.