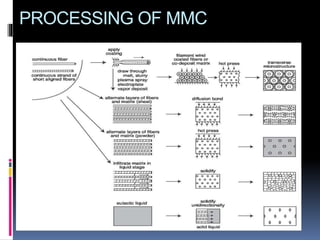

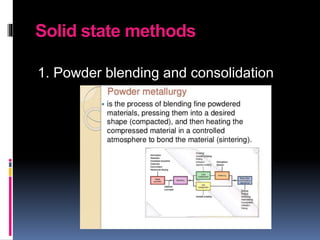

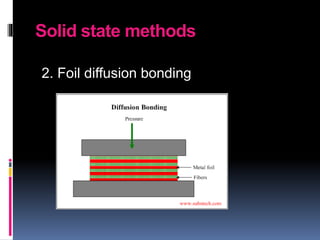

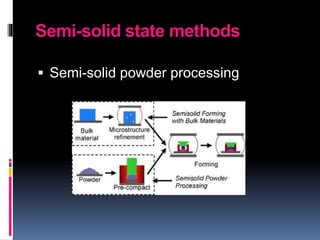

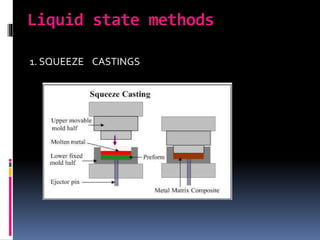

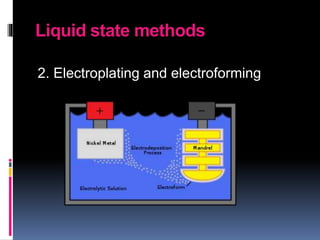

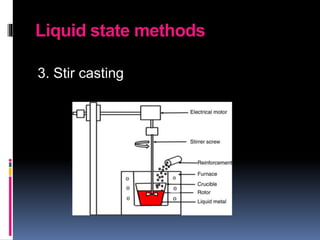

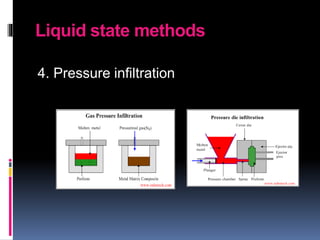

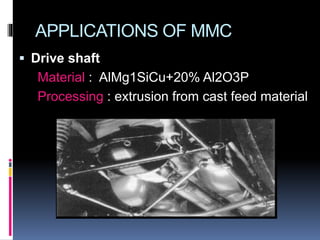

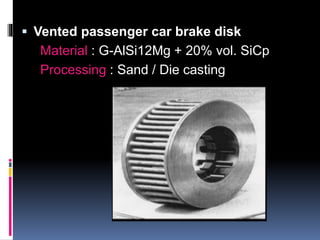

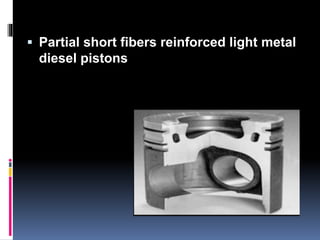

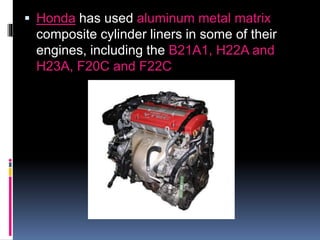

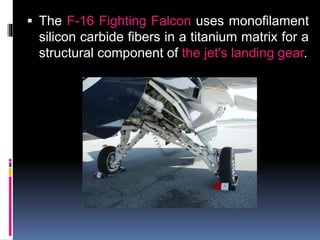

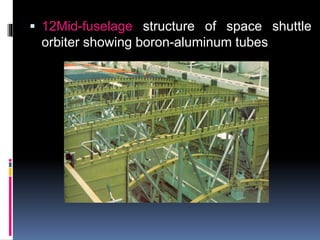

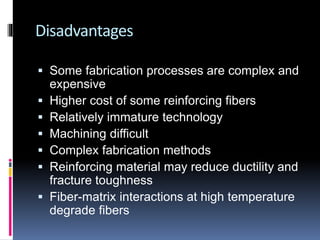

The document discusses metal matrix composites (MMCs), highlighting their composition, processing methods, applications, advantages, and disadvantages. MMCs are composite materials with a metal matrix and various reinforcements such as ceramics or other metals, offering high strength, stiffness, and resistance to wear. Future applications are anticipated in aerospace and defense, with a focus on increasing production efficiency and reducing costs.