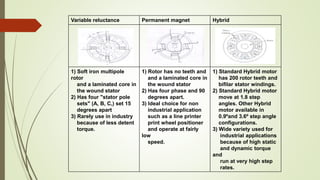

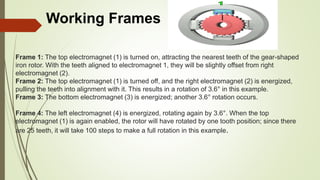

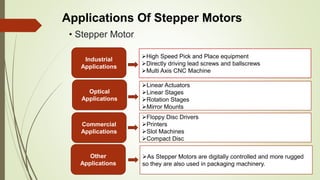

The document discusses stepper motors. It begins by introducing the three members of the presentation group and listing the contents to be covered, which include the introduction, working principle, speed control methodology, applications, advantages, and limitations of stepper motors. It then defines a stepper motor as a brushless DC electric motor that divides a full rotation into a number of equal steps. The document goes on to describe the three main types of stepper motors and explain their working principles. It also discusses the various ways to control the speed of stepper motors, including using series resistance, gearboxes, and voltage regulation. Finally, the common applications, advantages, and limitations of stepper motors are summarized.