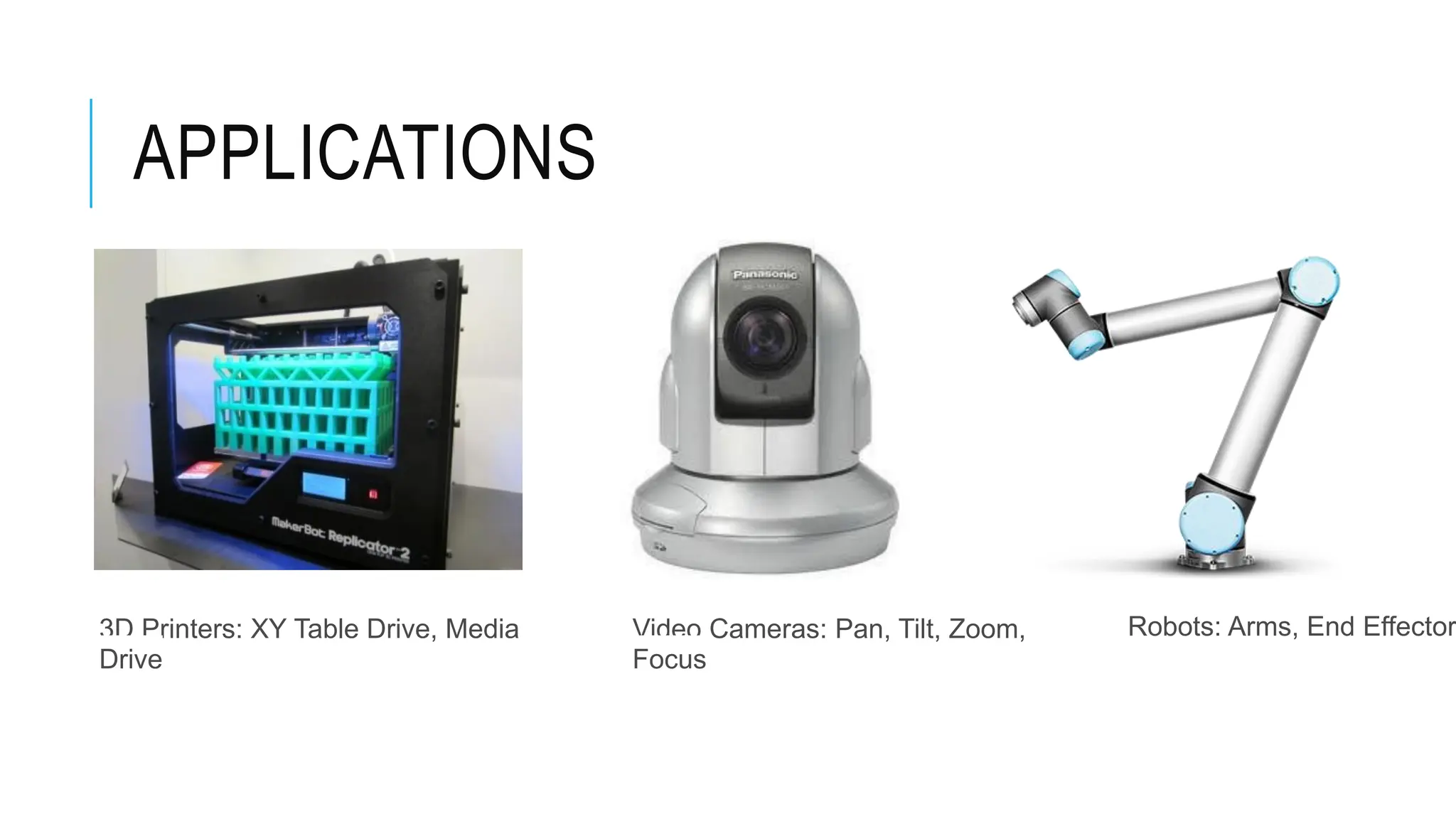

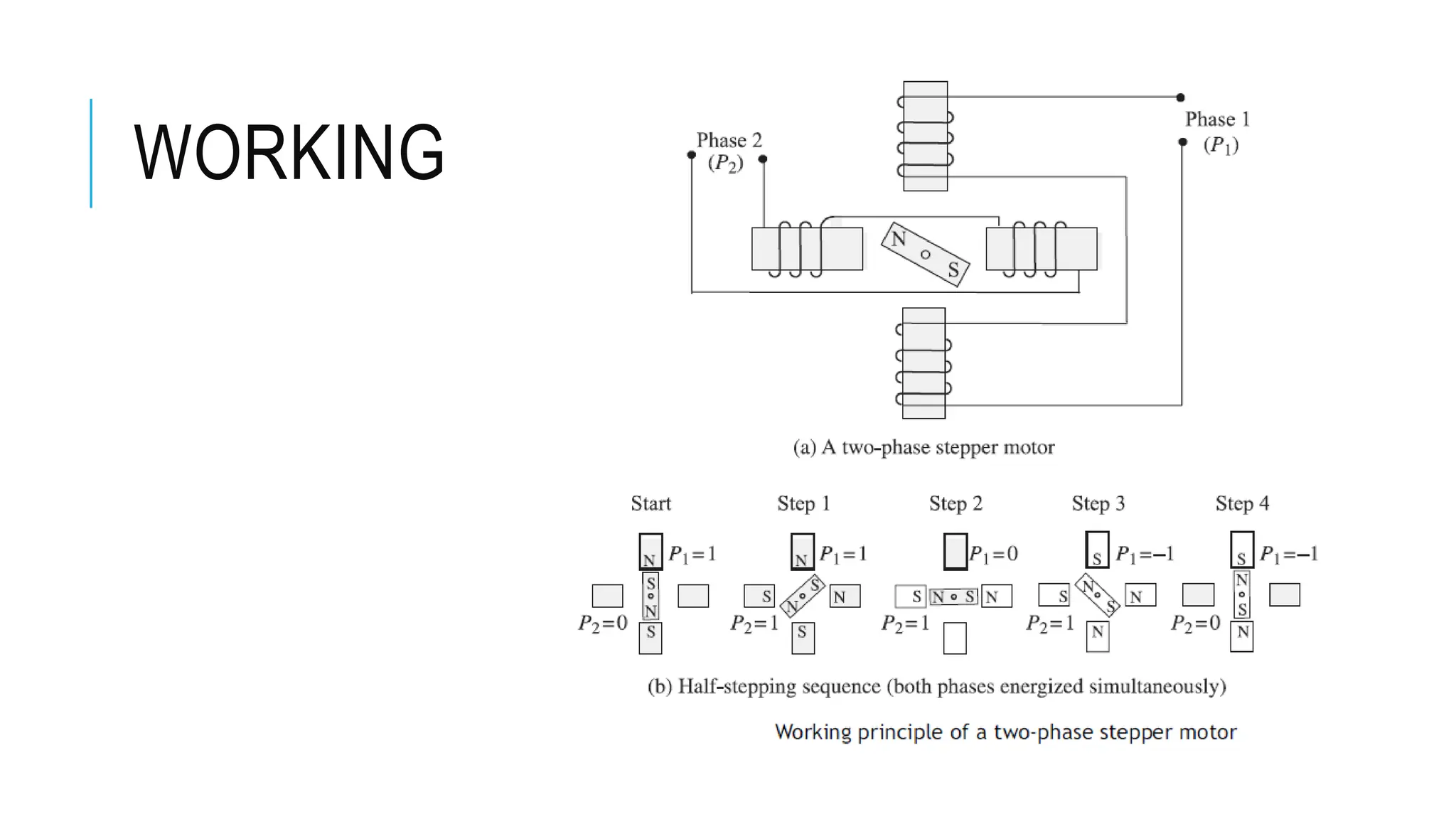

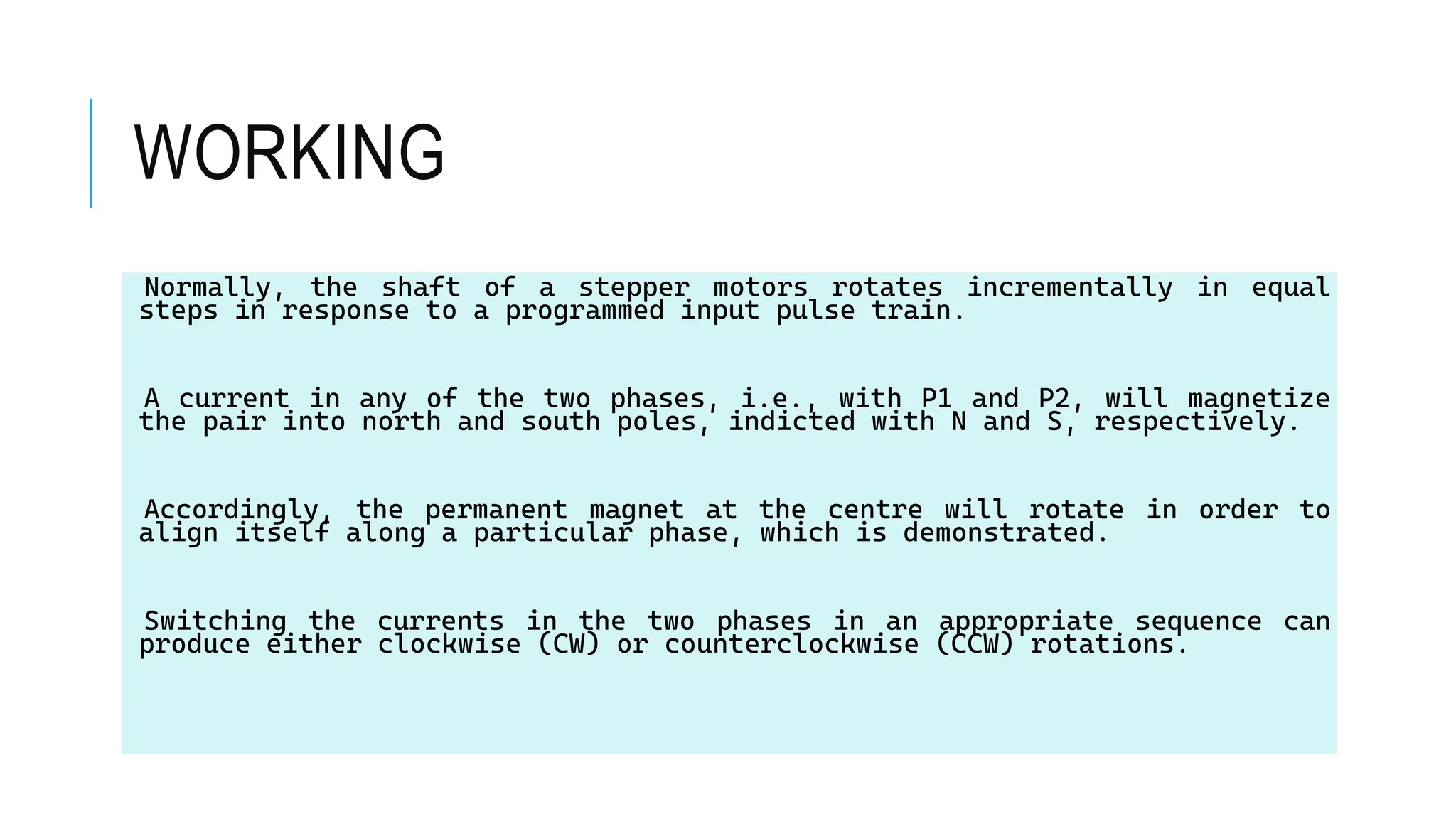

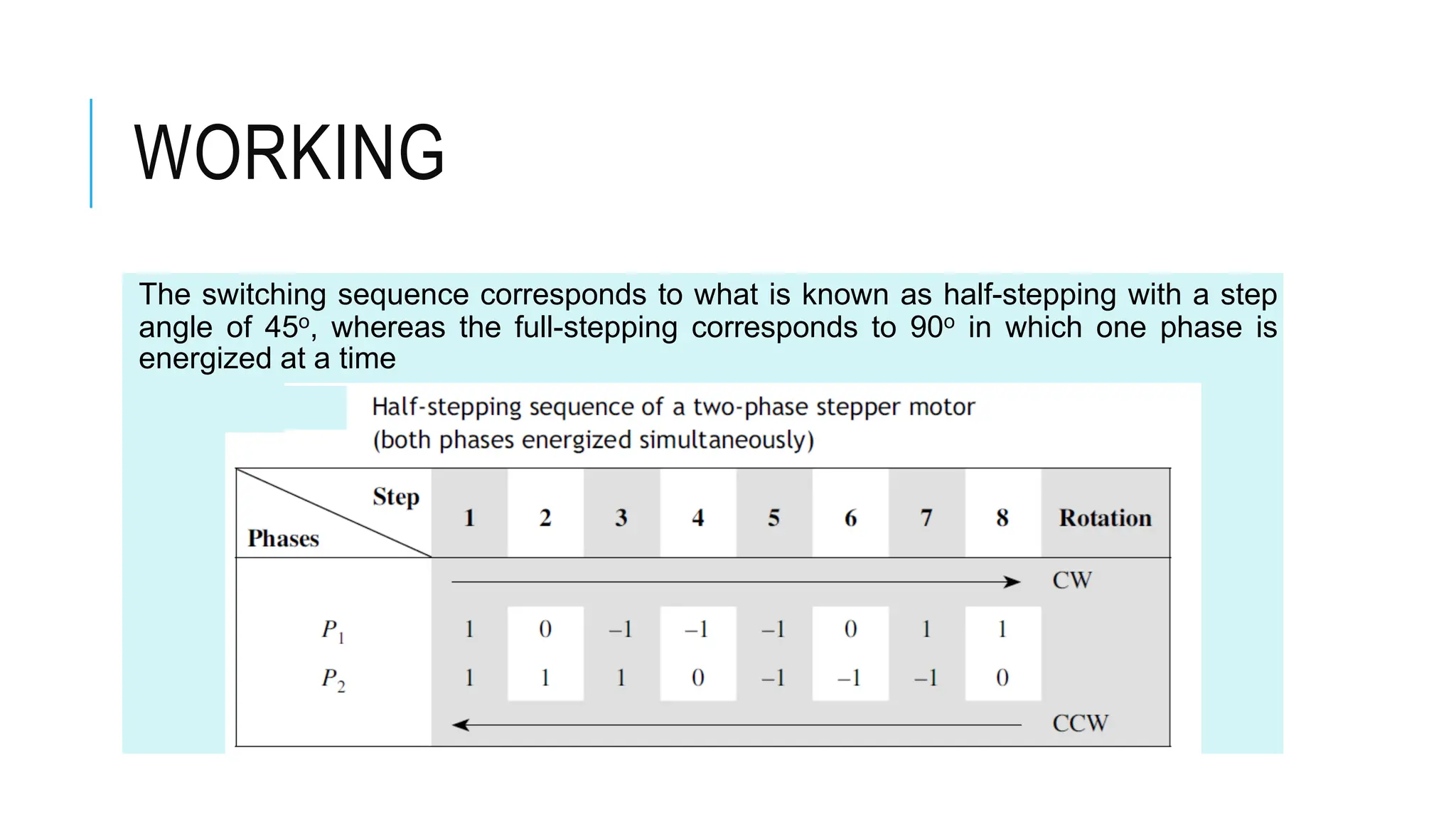

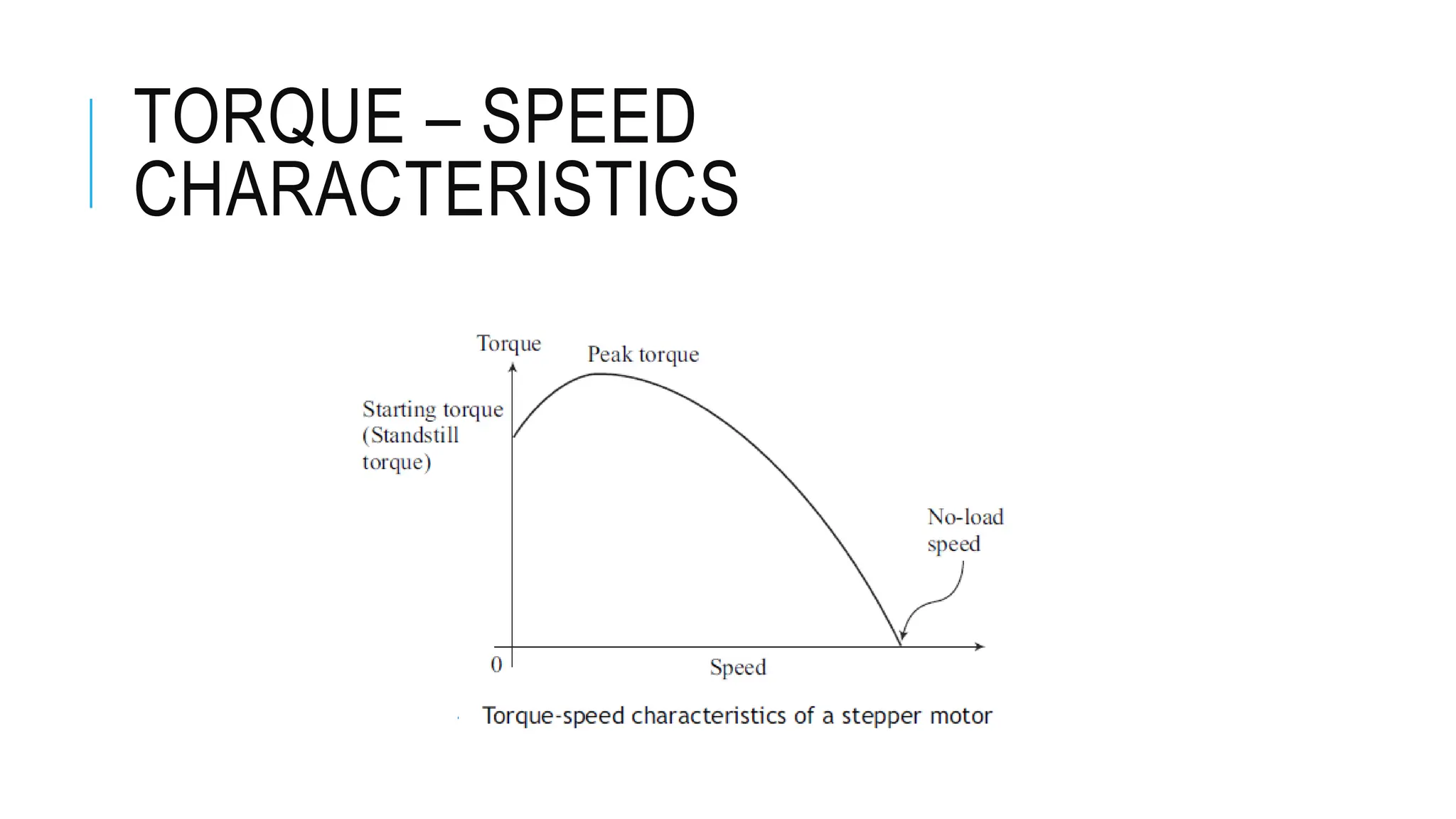

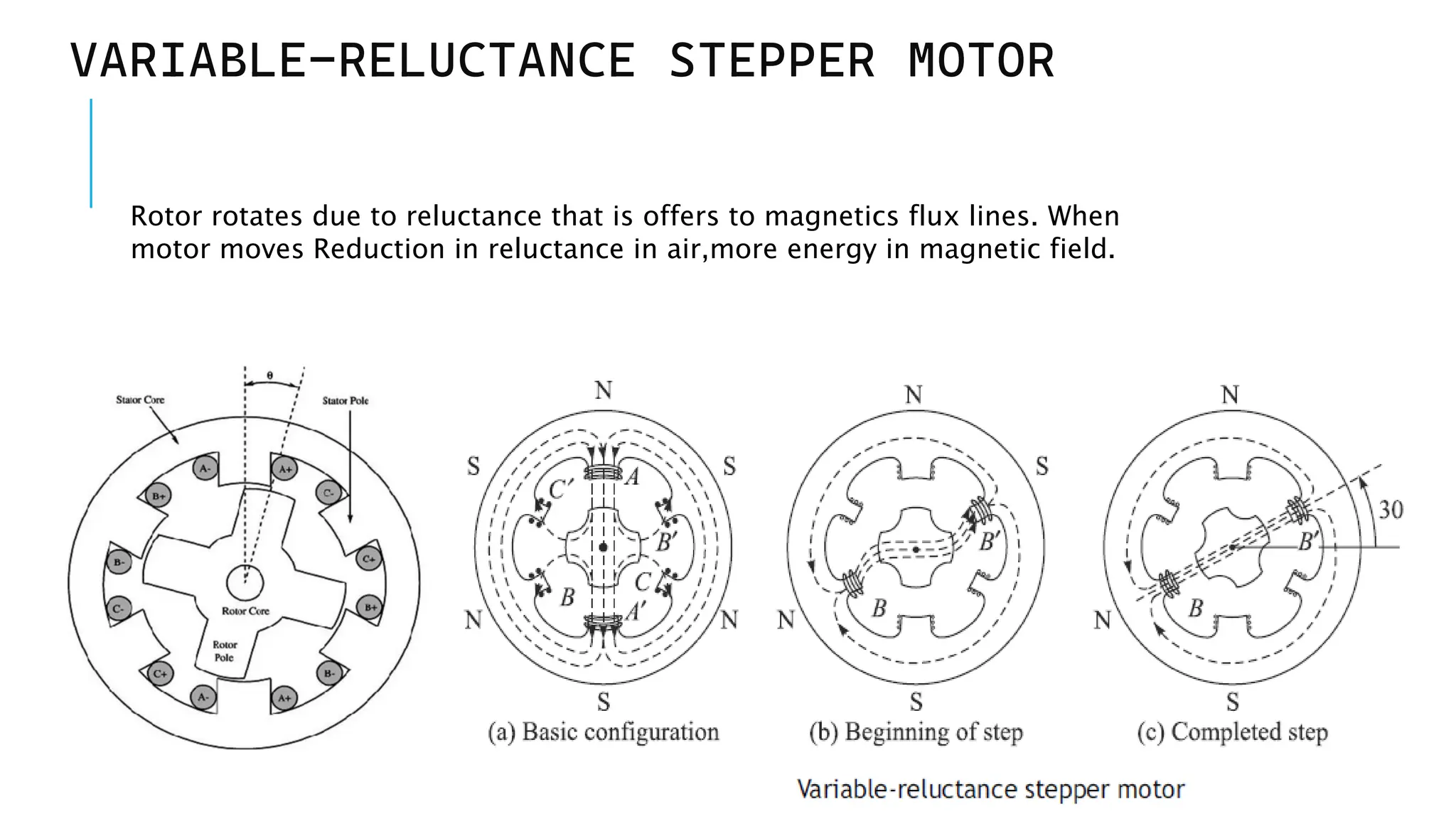

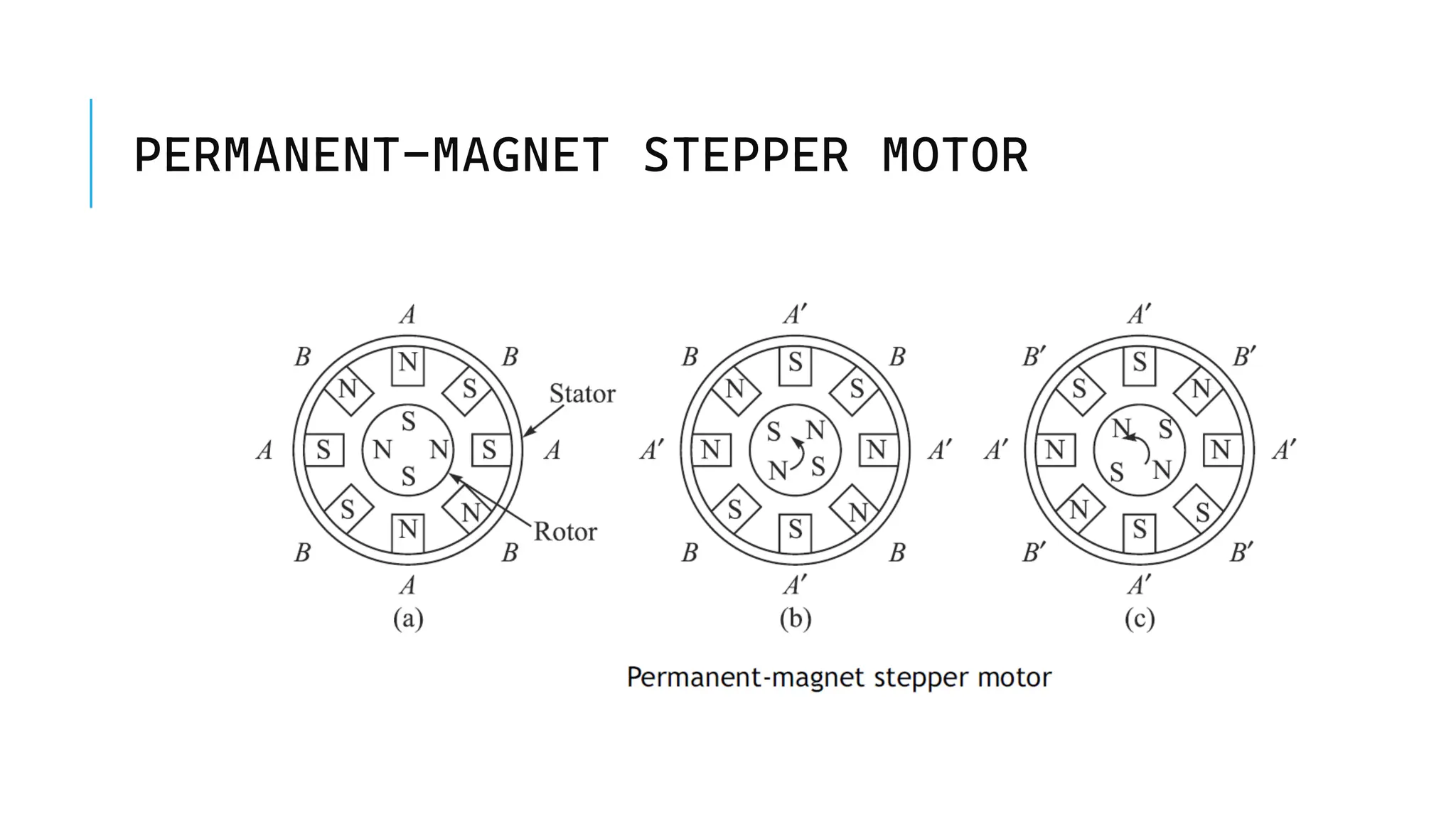

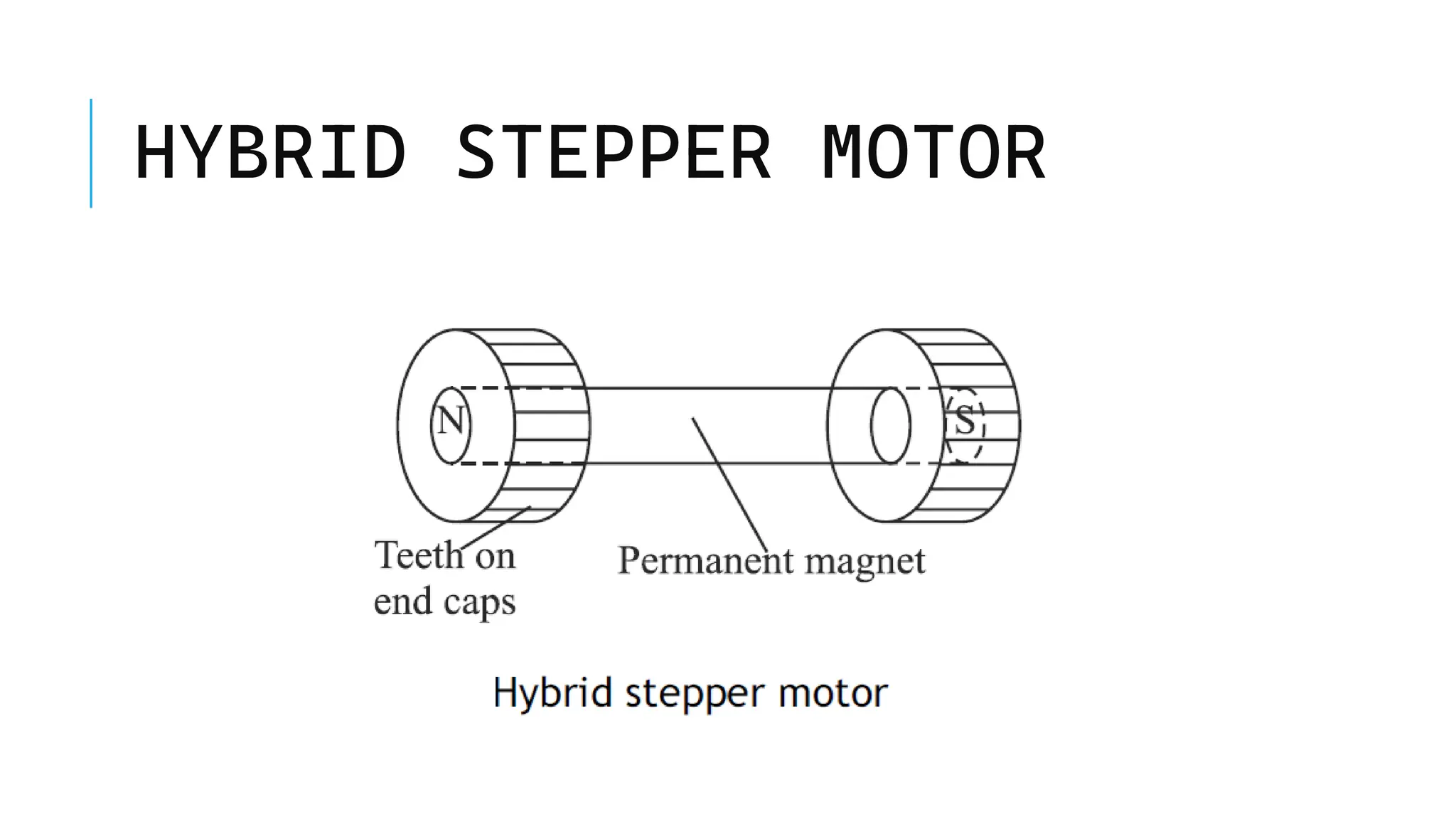

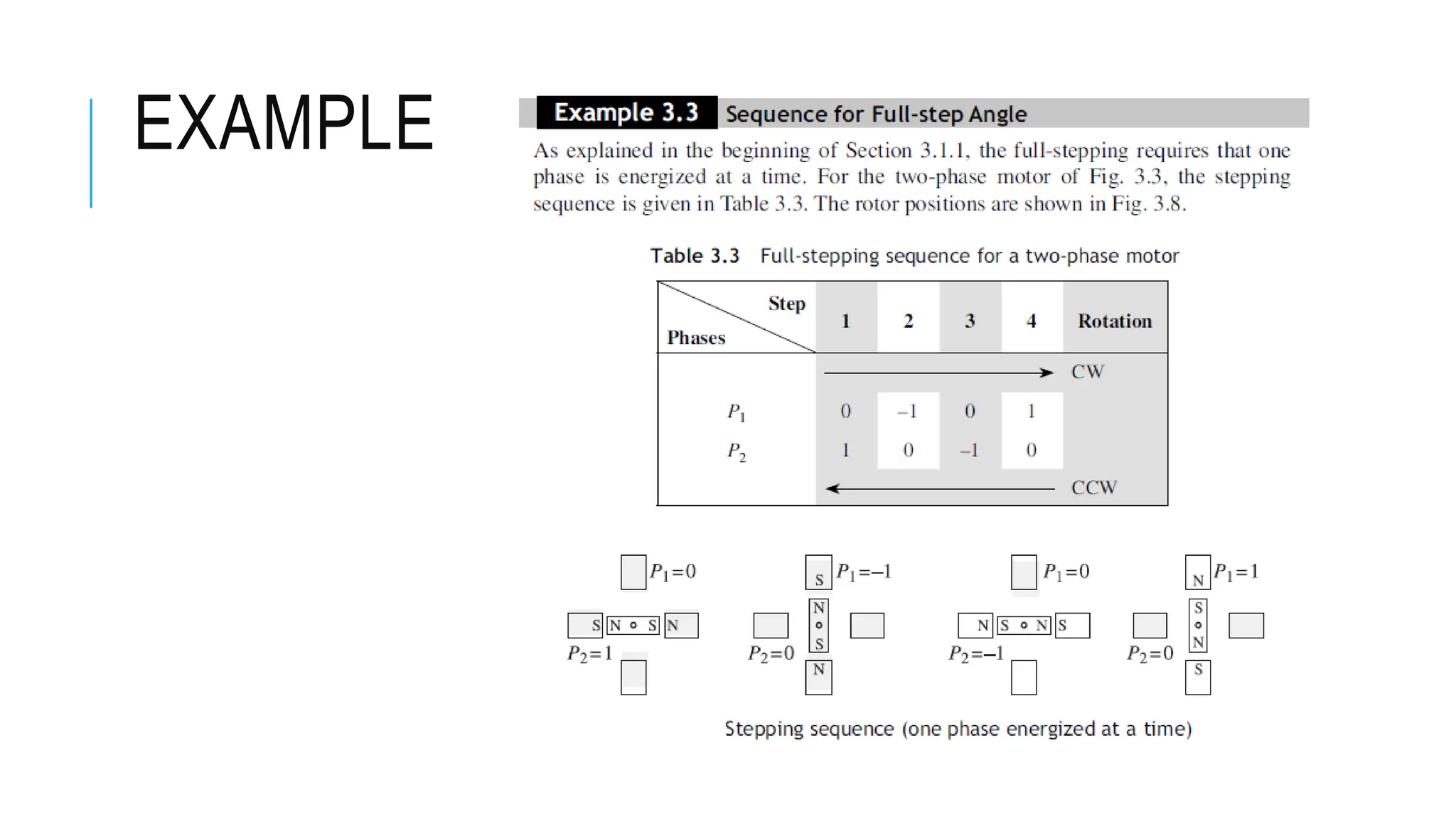

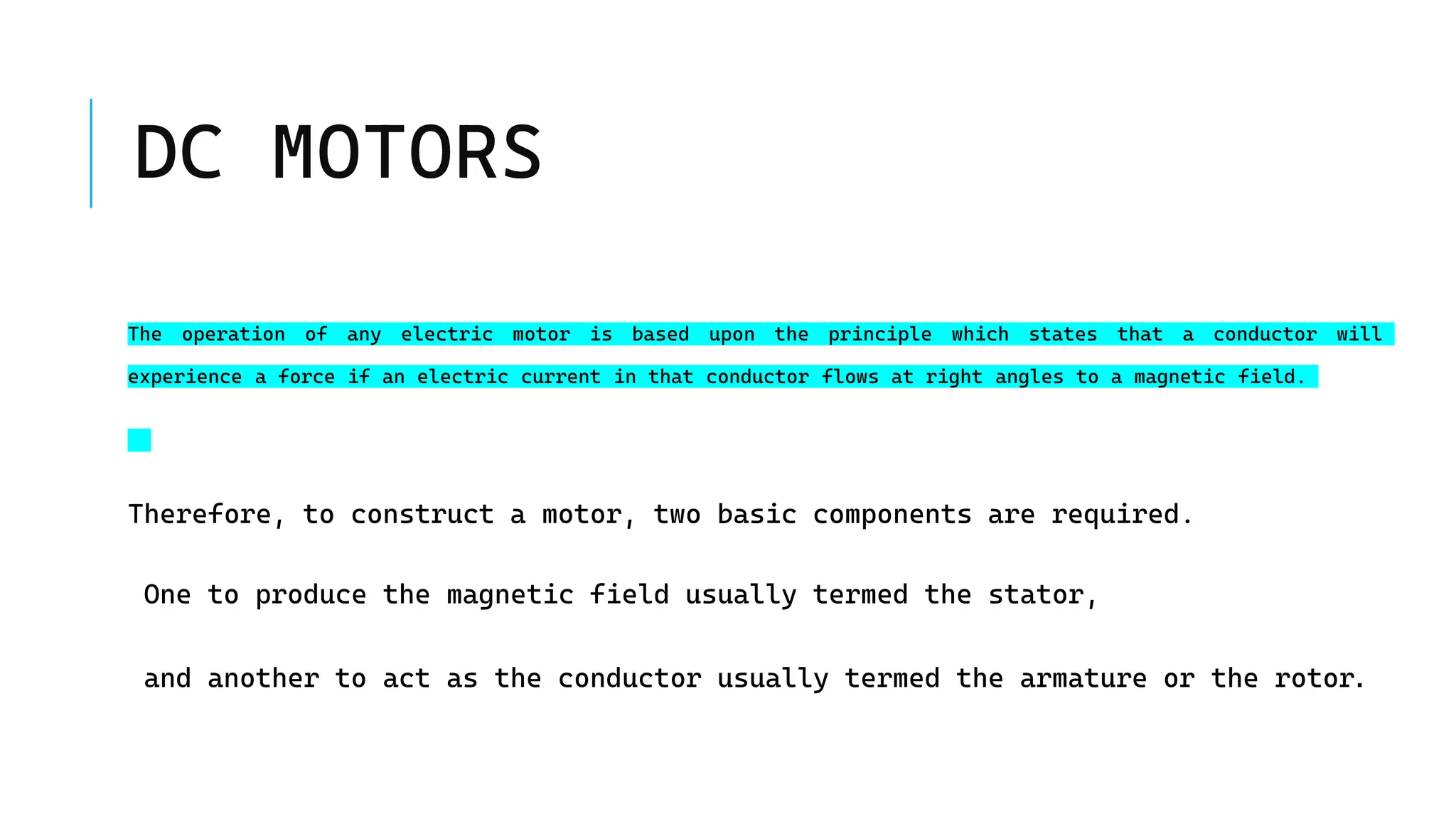

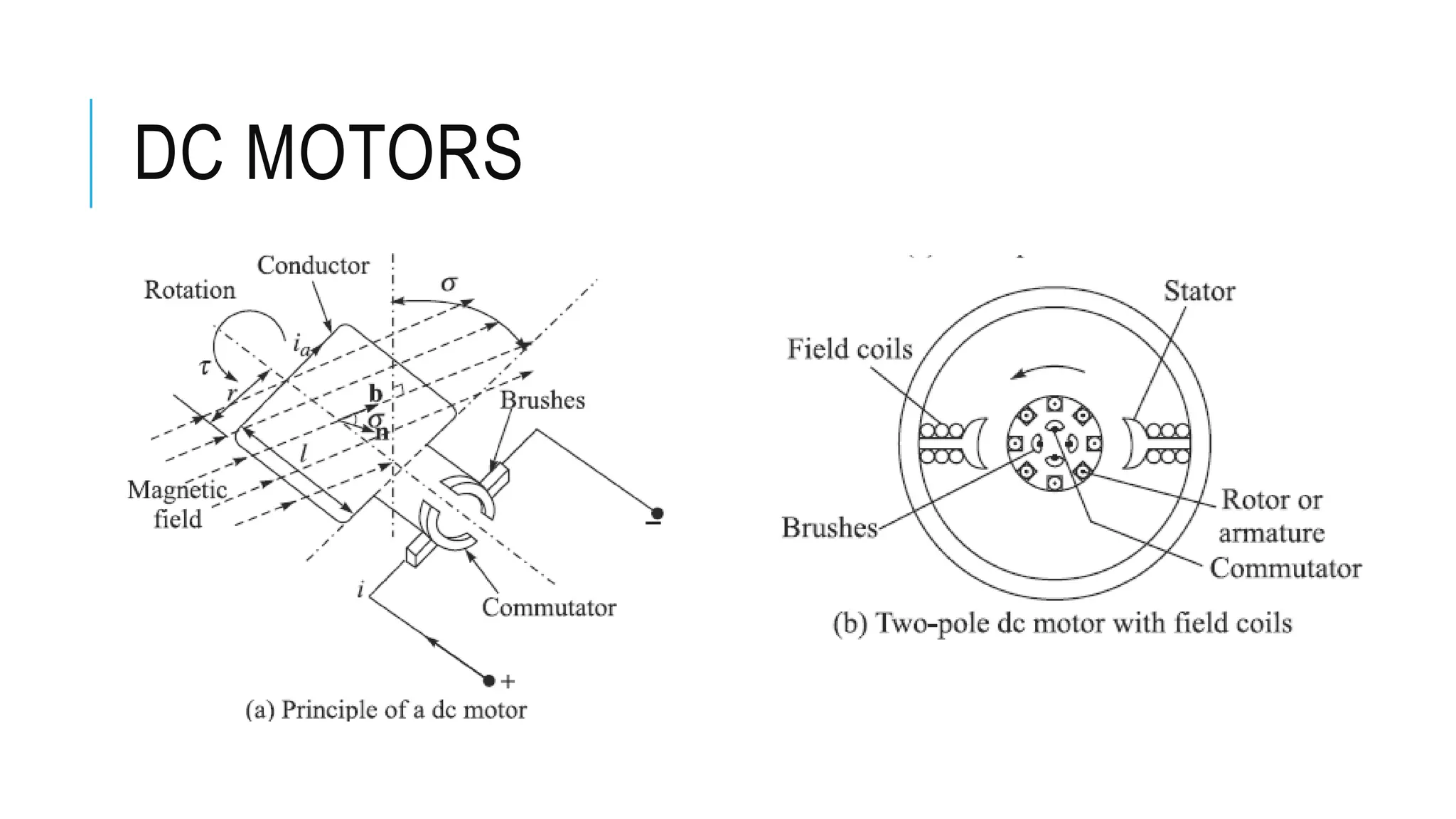

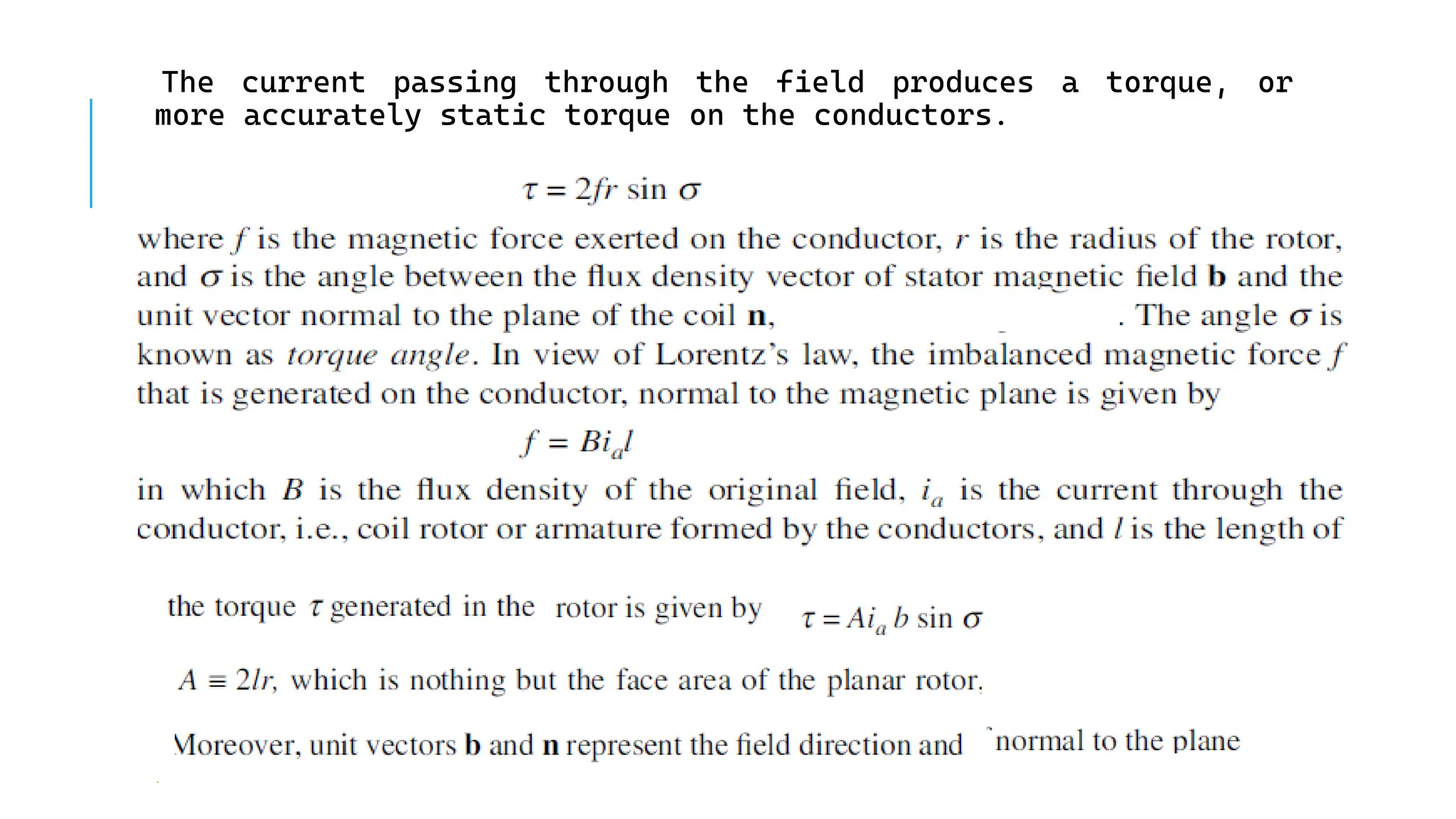

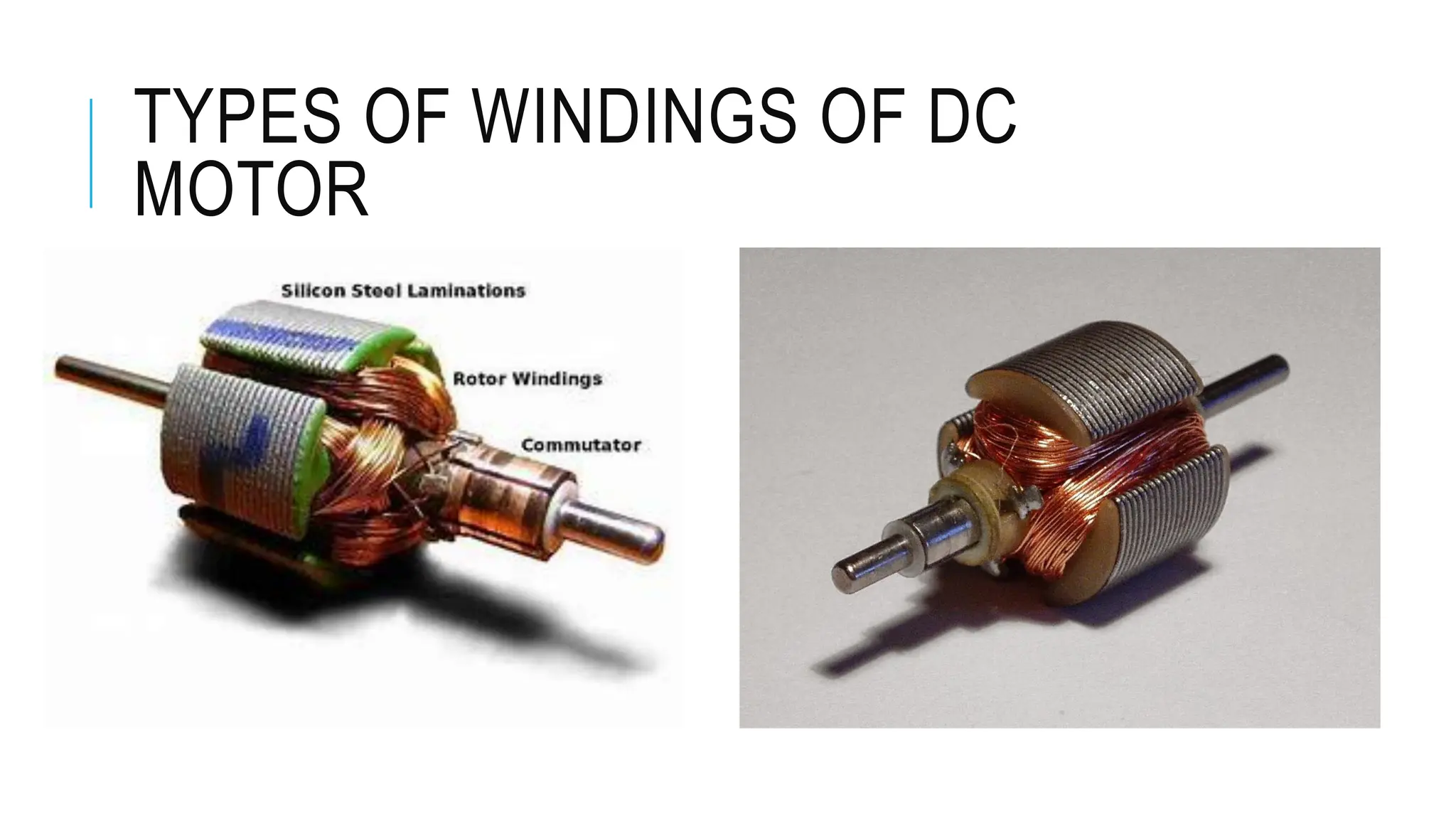

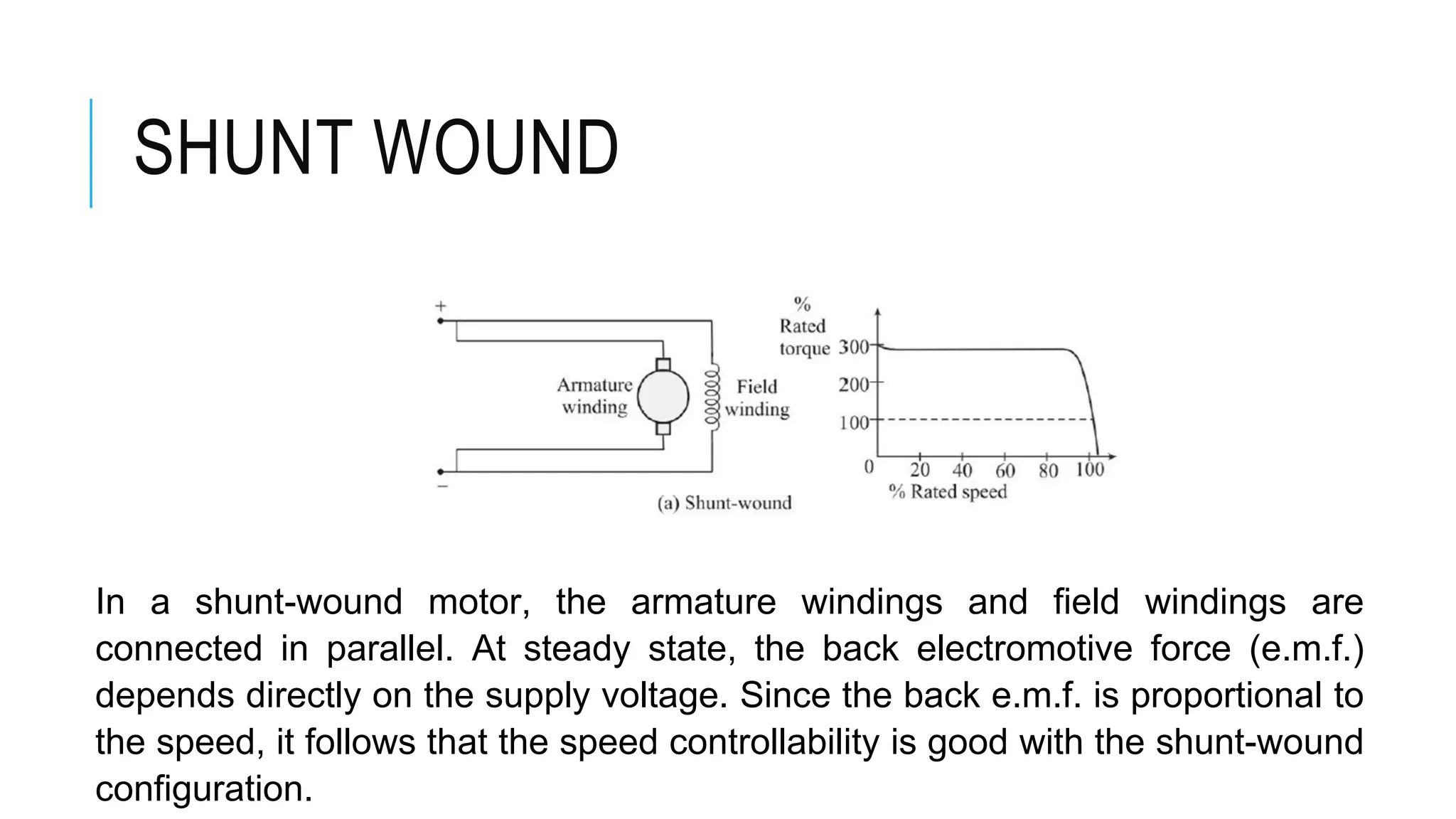

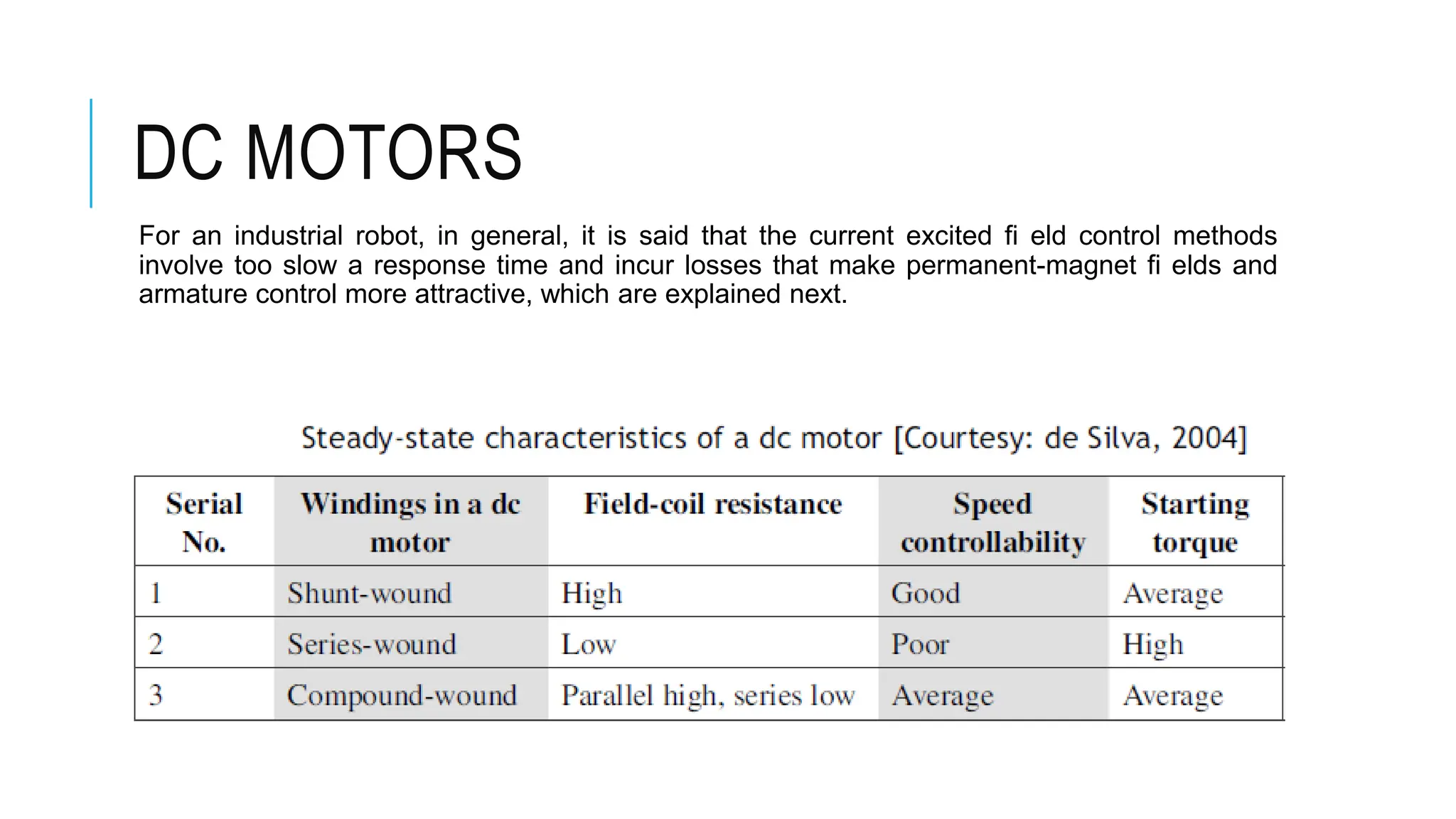

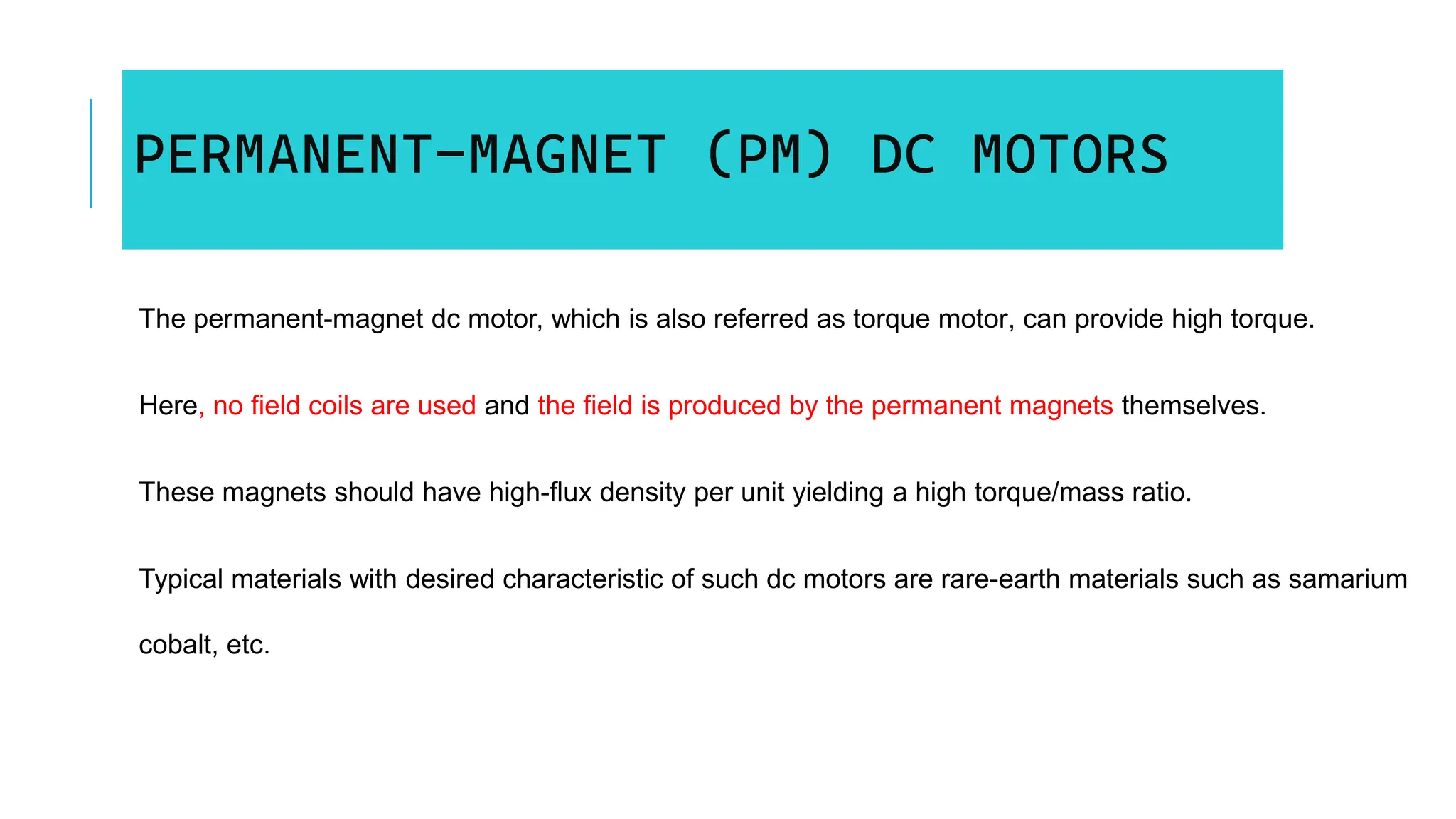

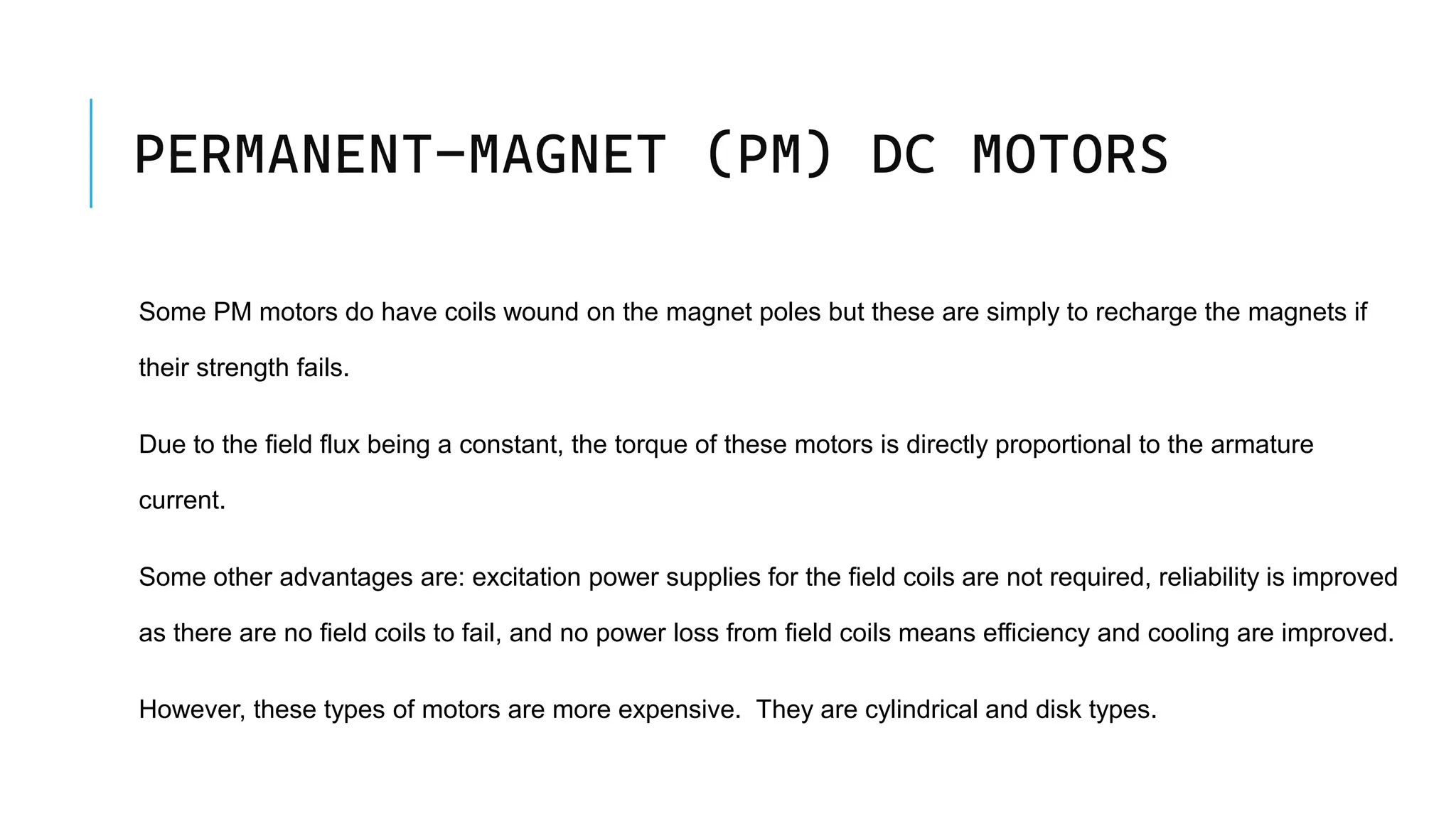

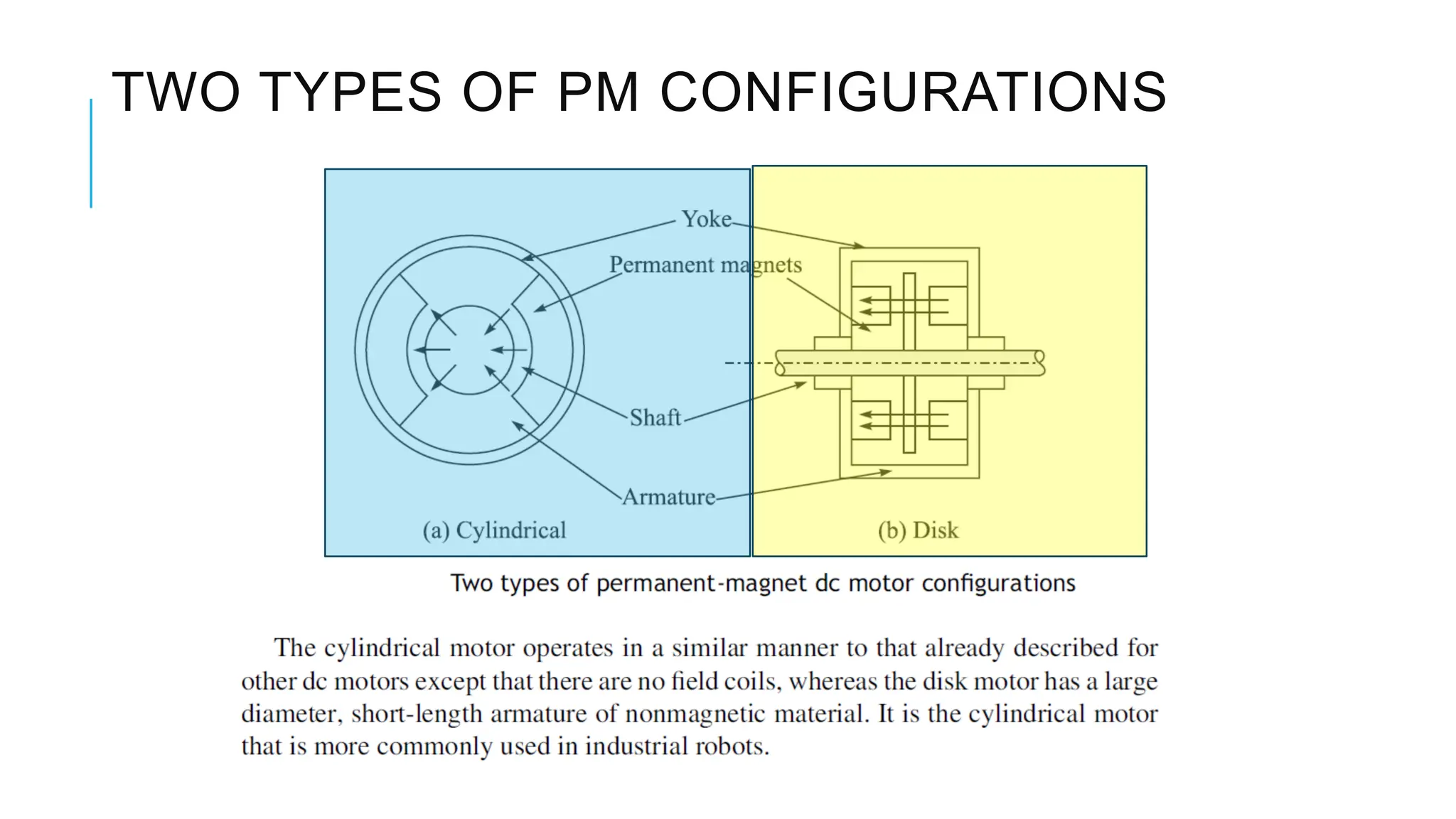

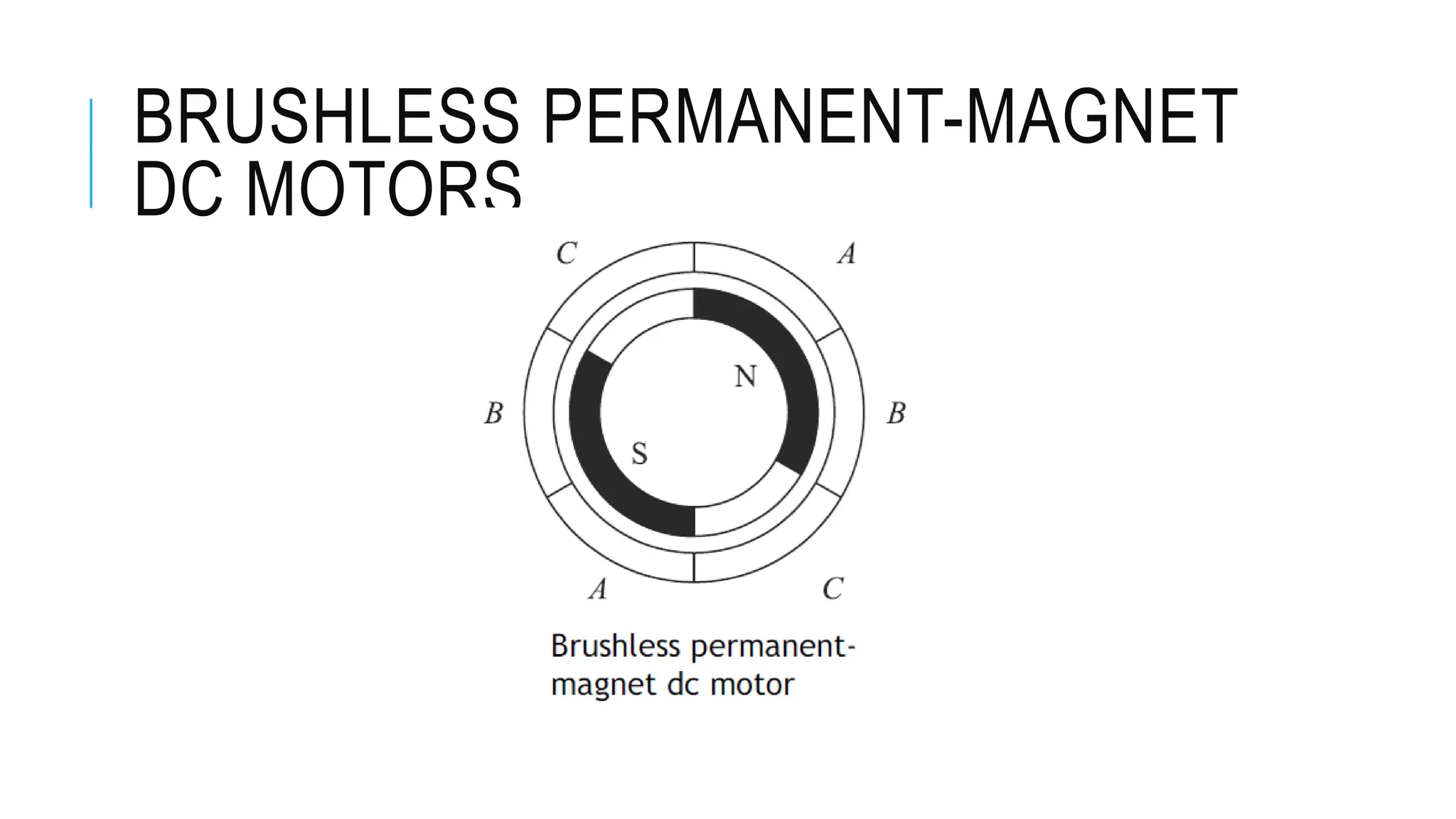

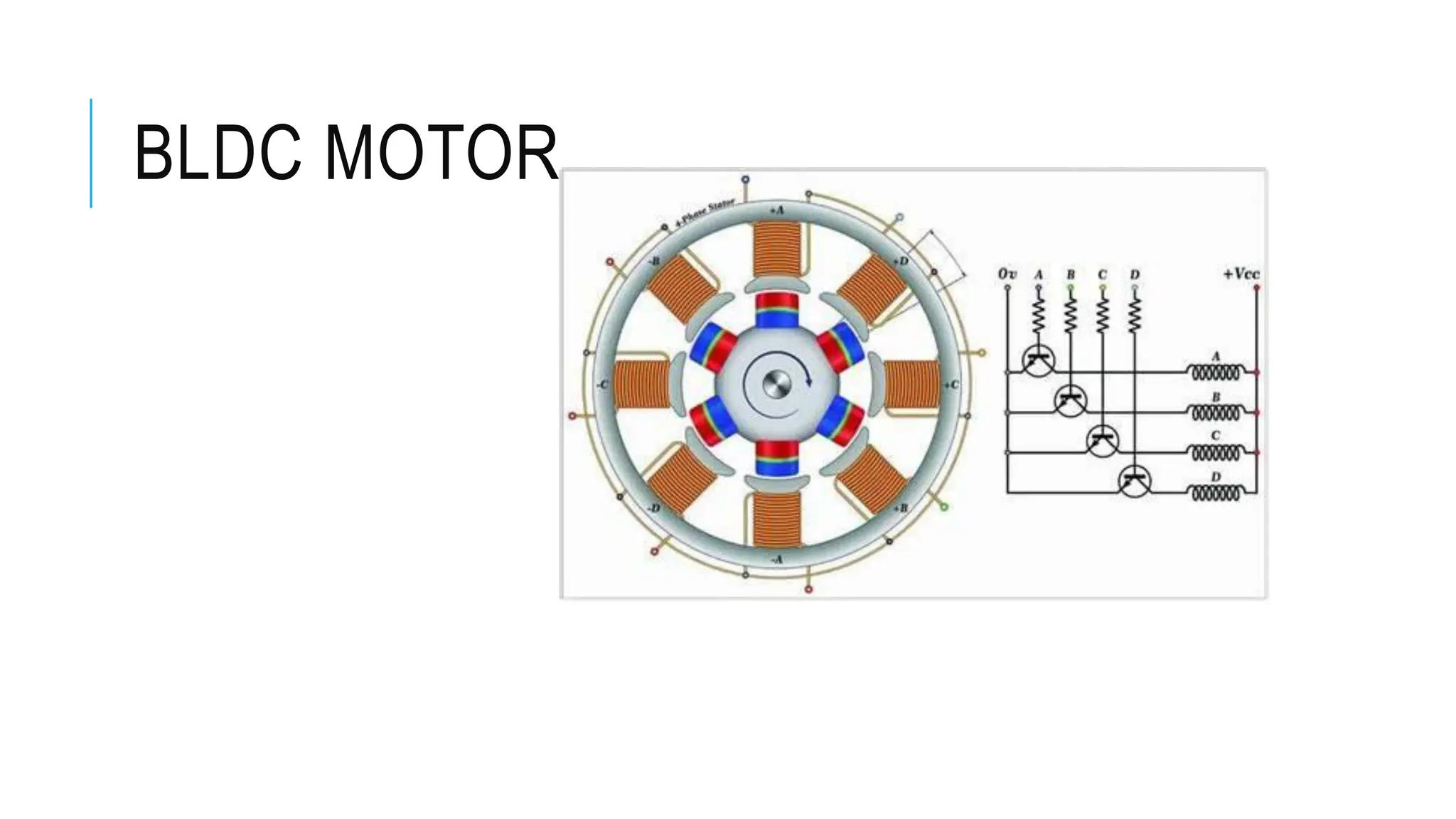

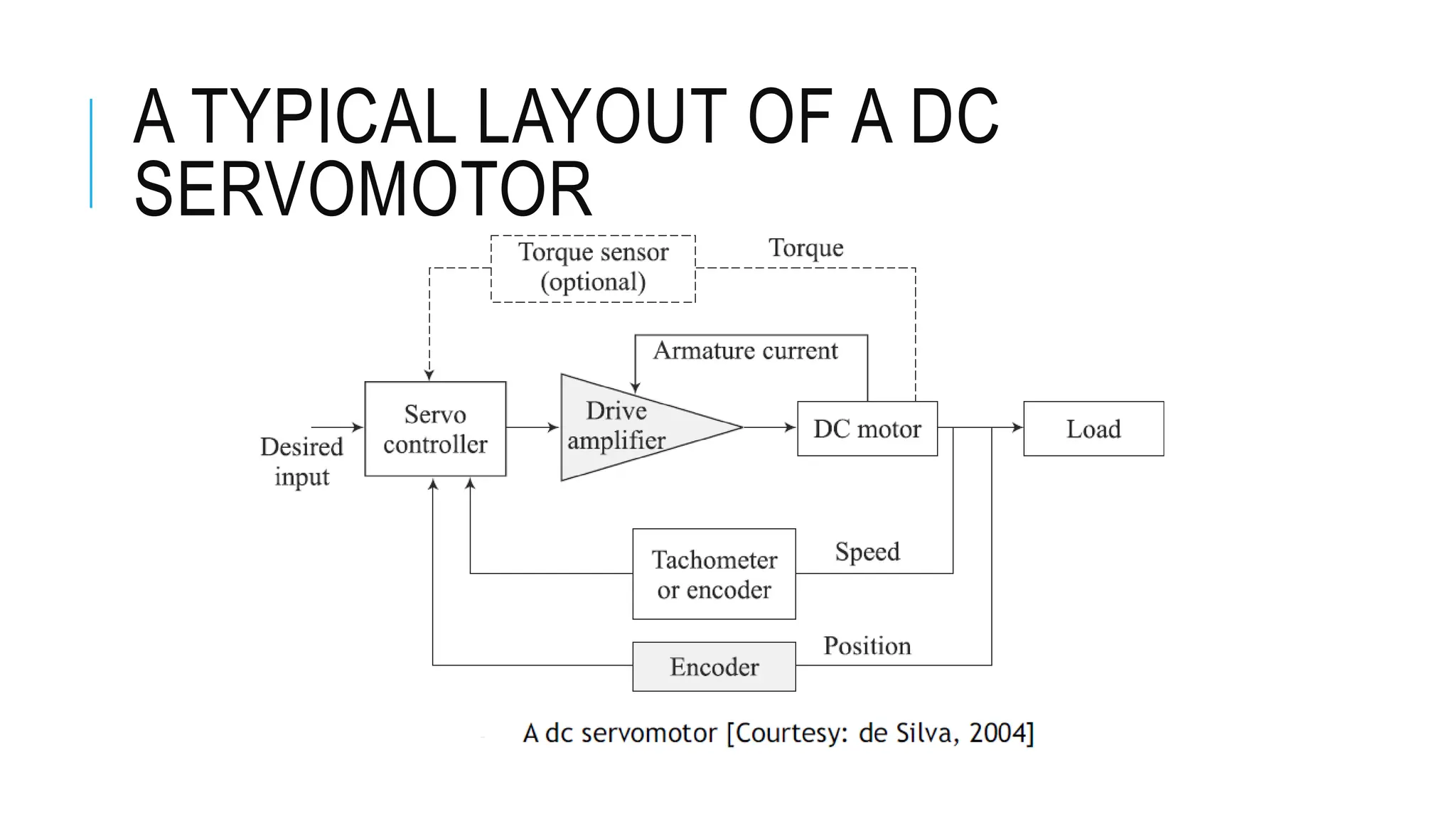

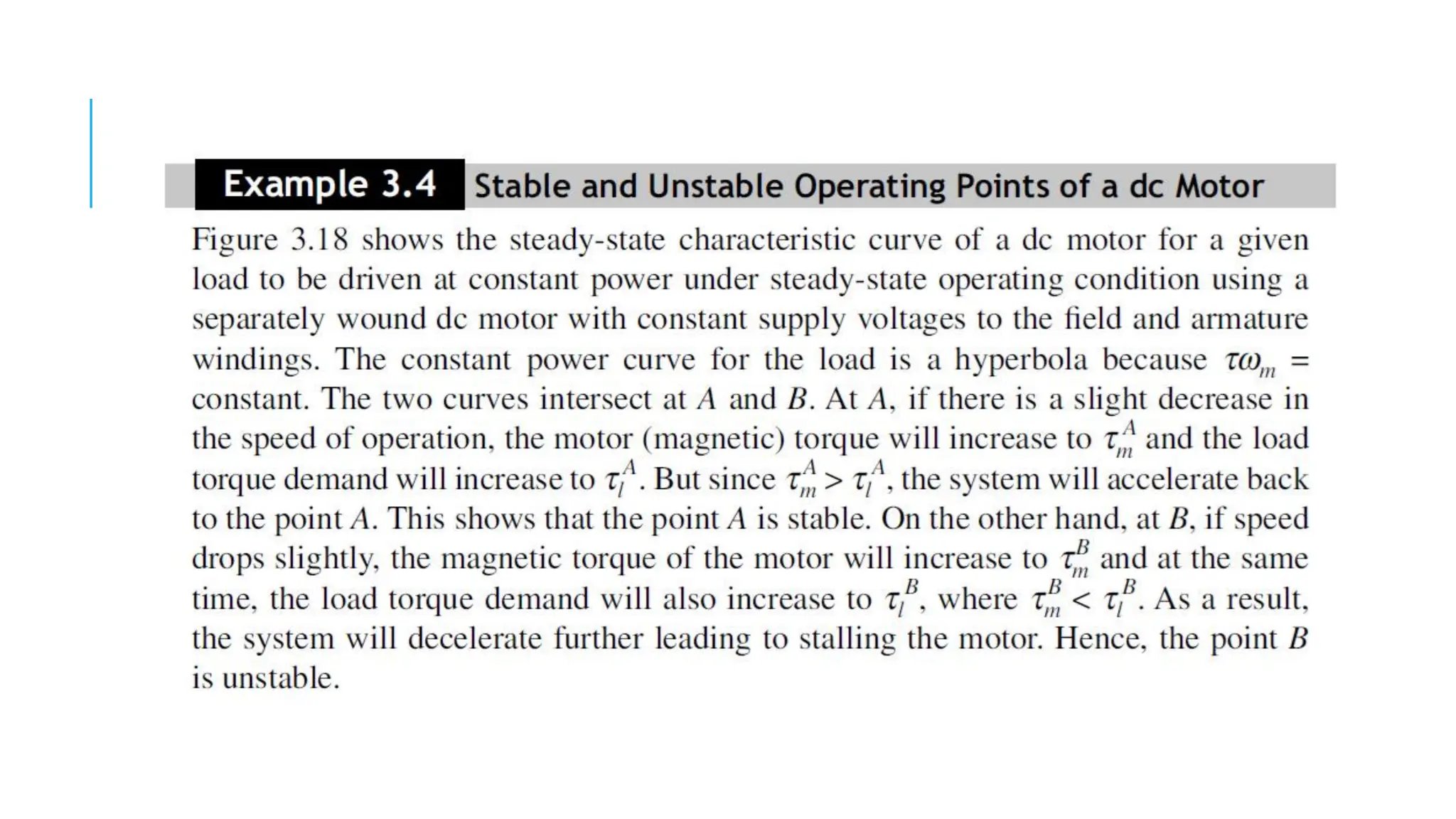

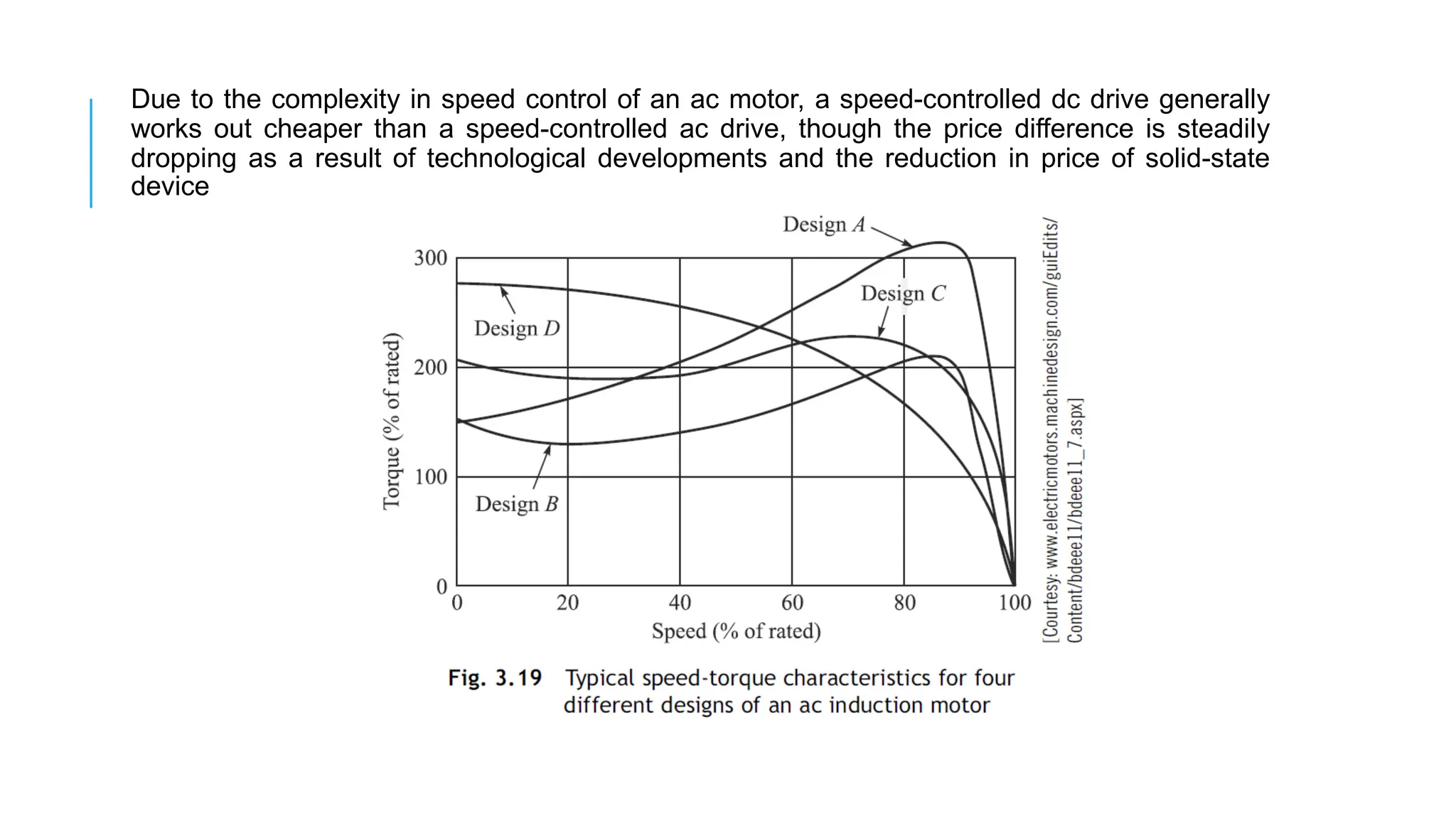

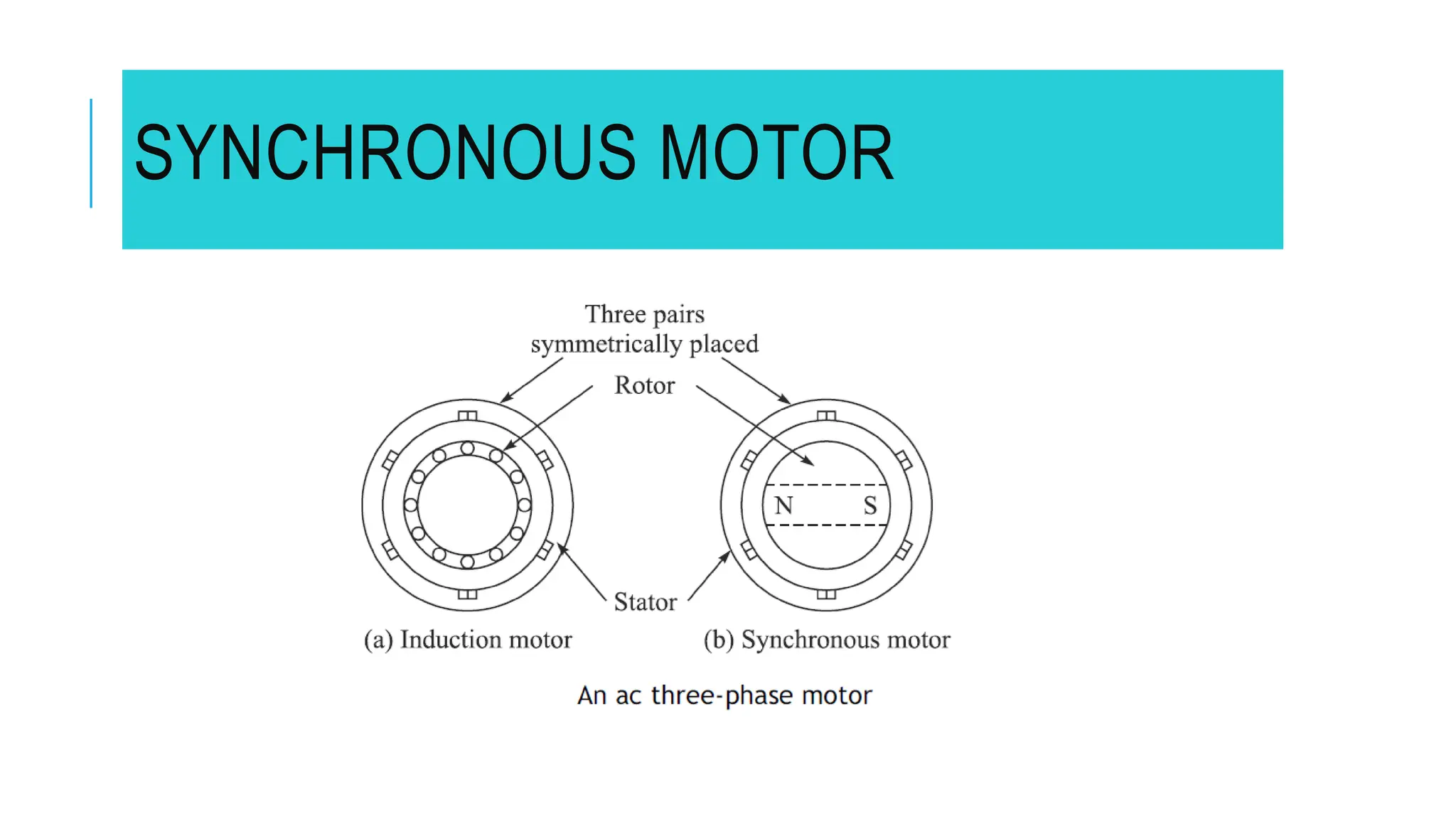

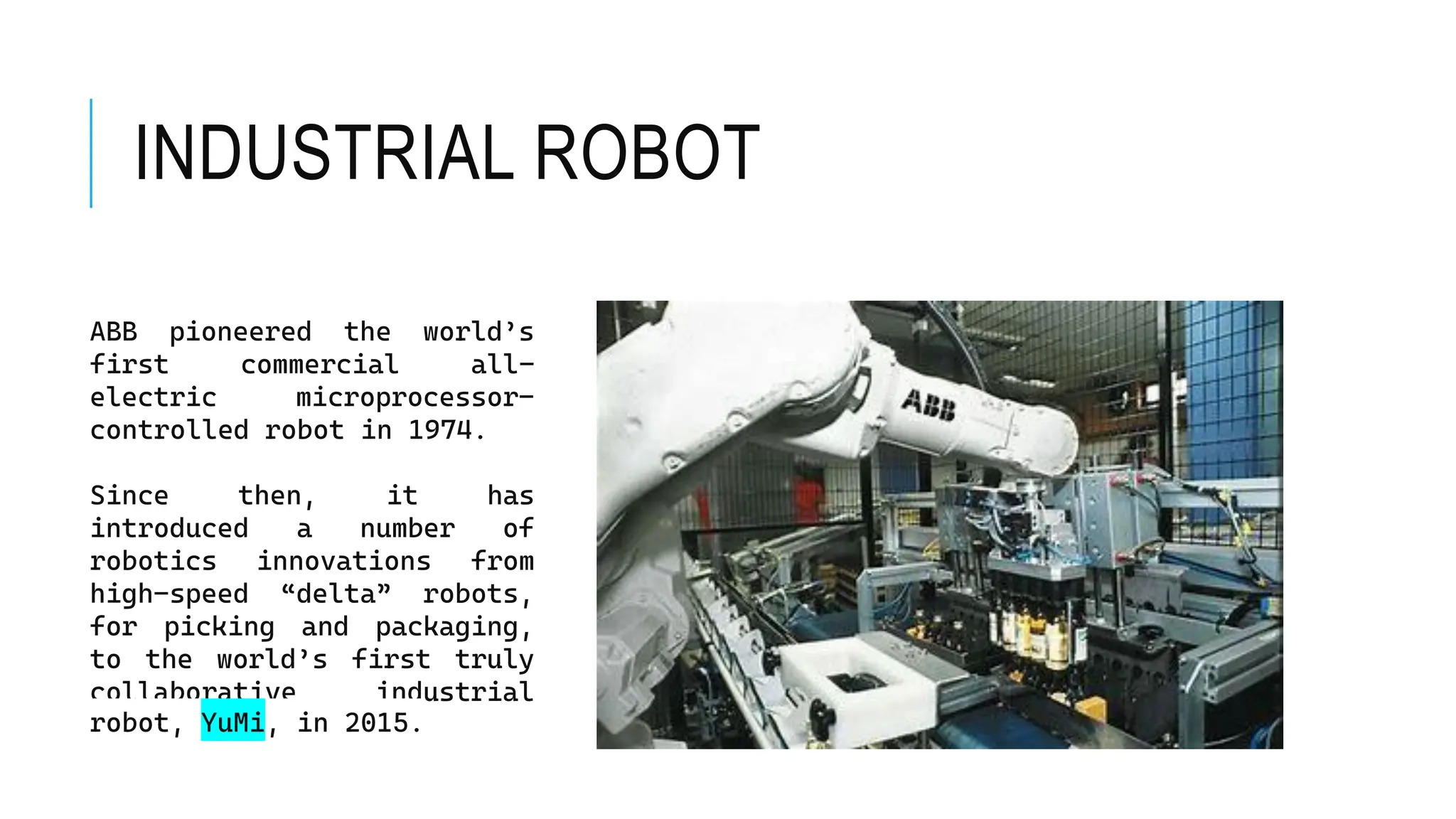

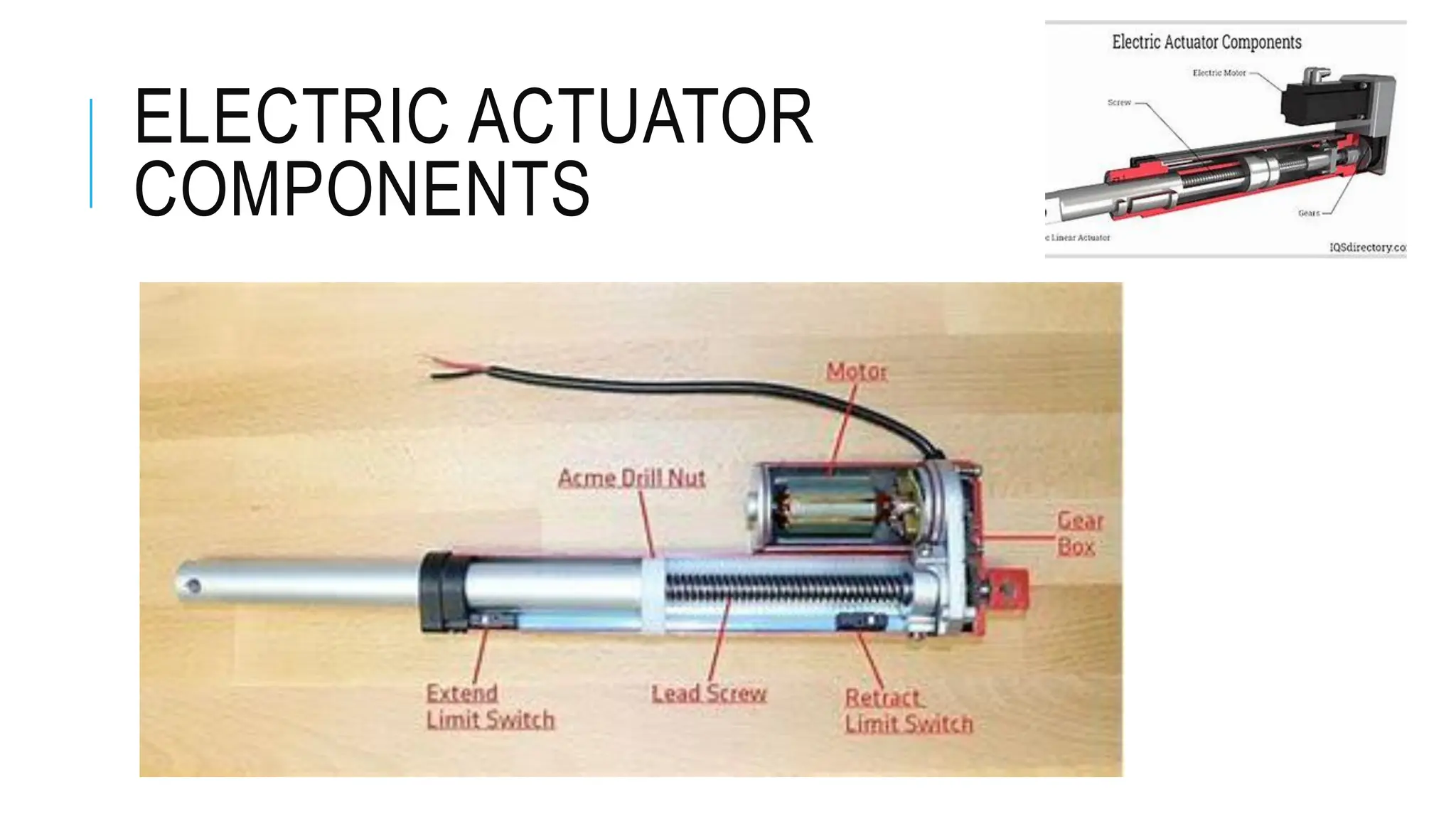

The document discusses various types of actuators and grippers used in robotics, particularly focusing on electric, hydraulic, and pneumatic actuators. It highlights the advantages and disadvantages of electric actuators, including characteristics of stepper motors and DC motors, detailing their workings, applications, and type classifications. Moreover, it presents an overview of current advancements in motor design, such as direct-drive systems and brushless motors for improved performance and safety.

![STEPPER MOTORS

Stepper motor (Bipolar, 200 Steps/Rev, 20 X 30 mm, 3.9 V, 0.6 A/Phase)

[Courtesy: http://www.polulu.com]](https://image.slidesharecdn.com/m2-240707044214-643355b7/75/Module-2-Electric-Actuators-electrical-engineering-robotics-13-2048.jpg)