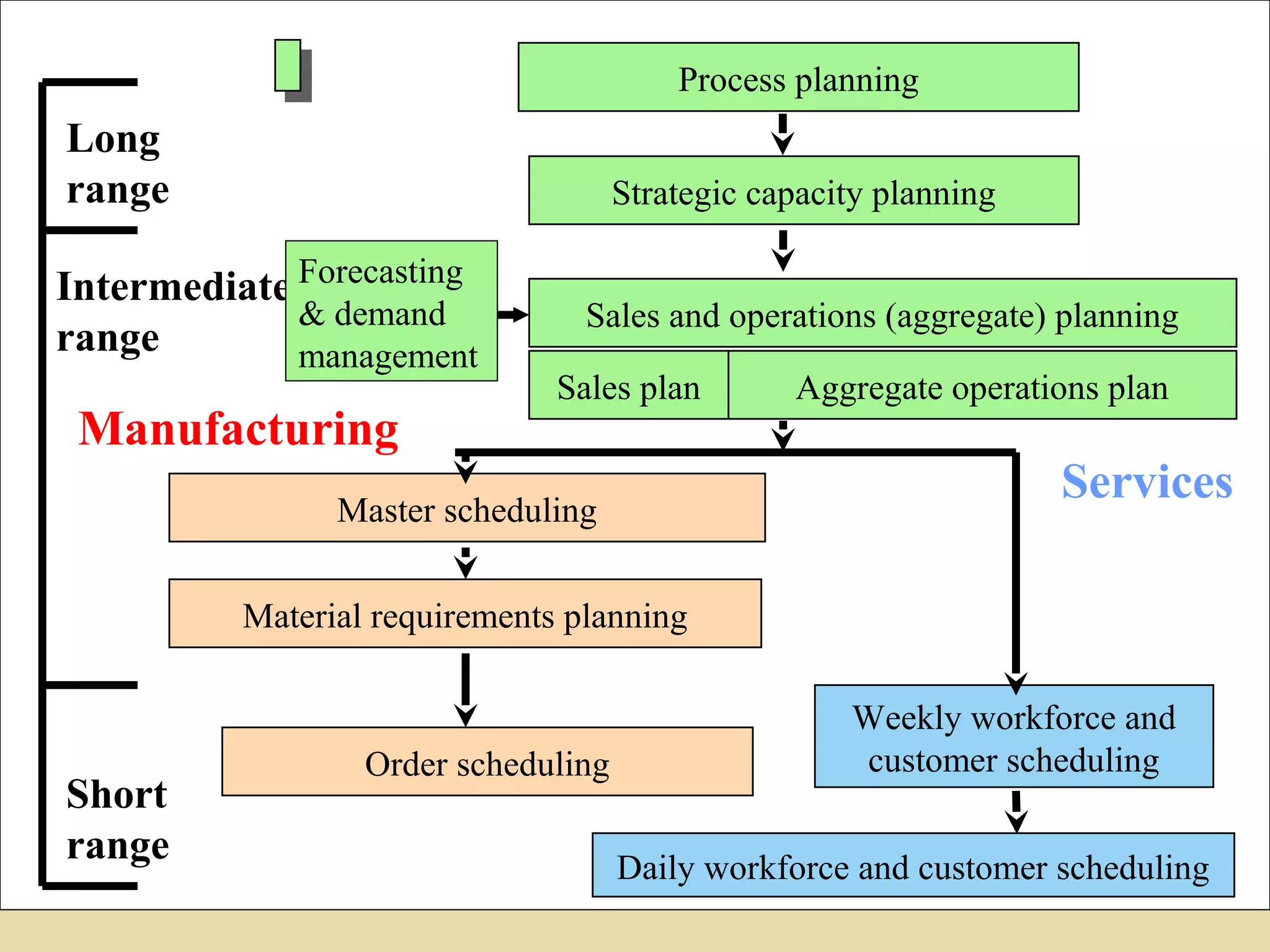

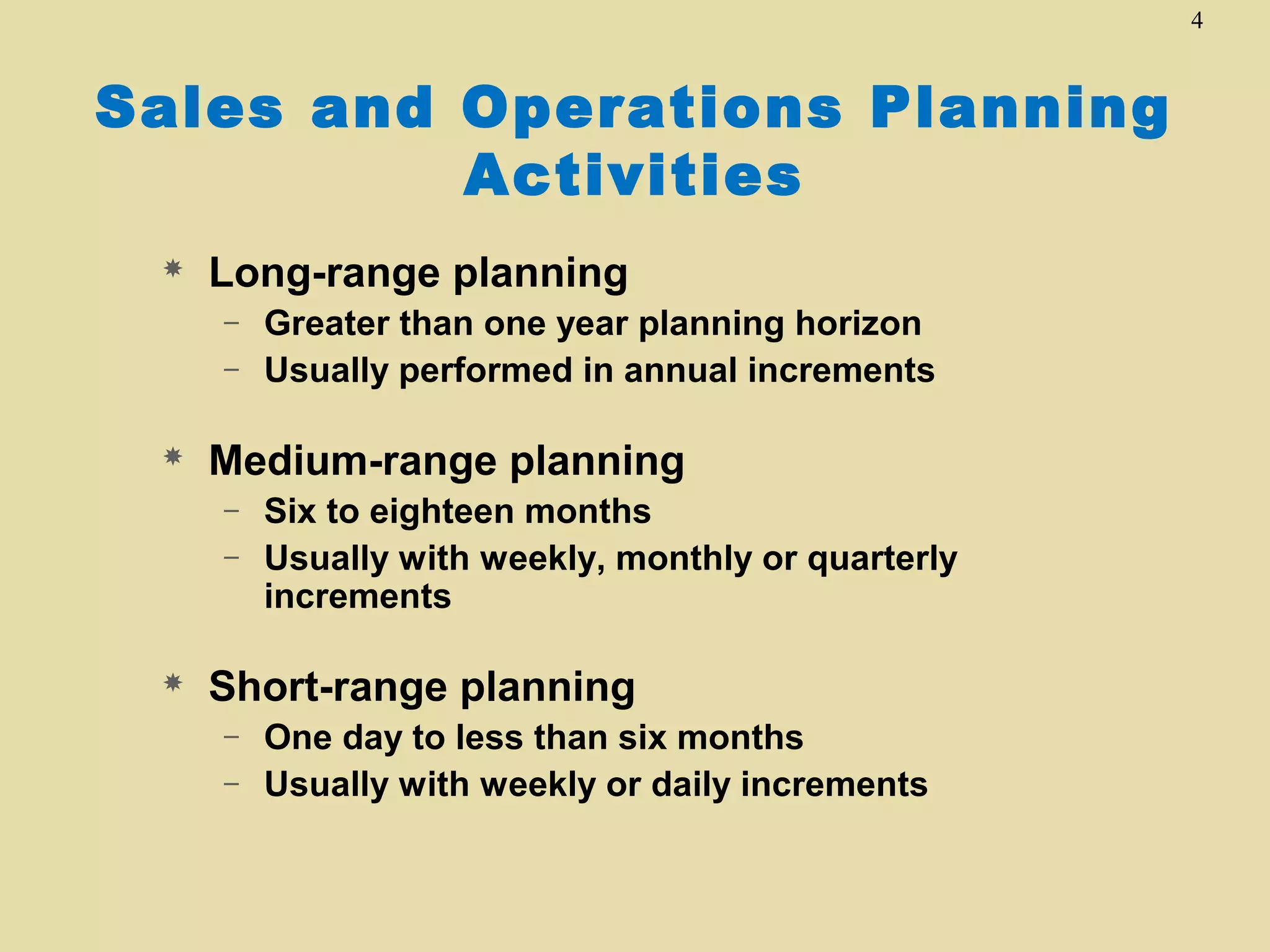

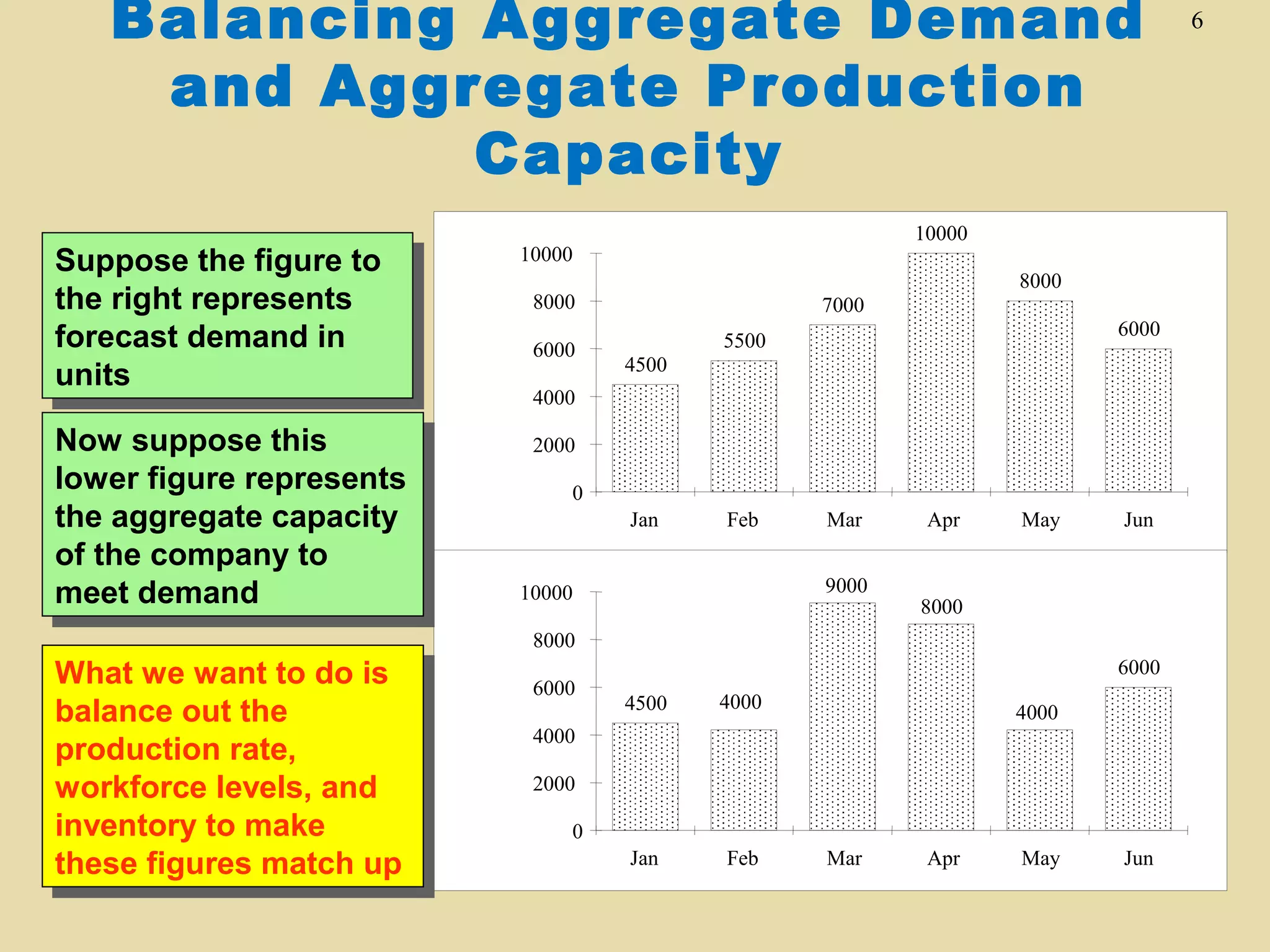

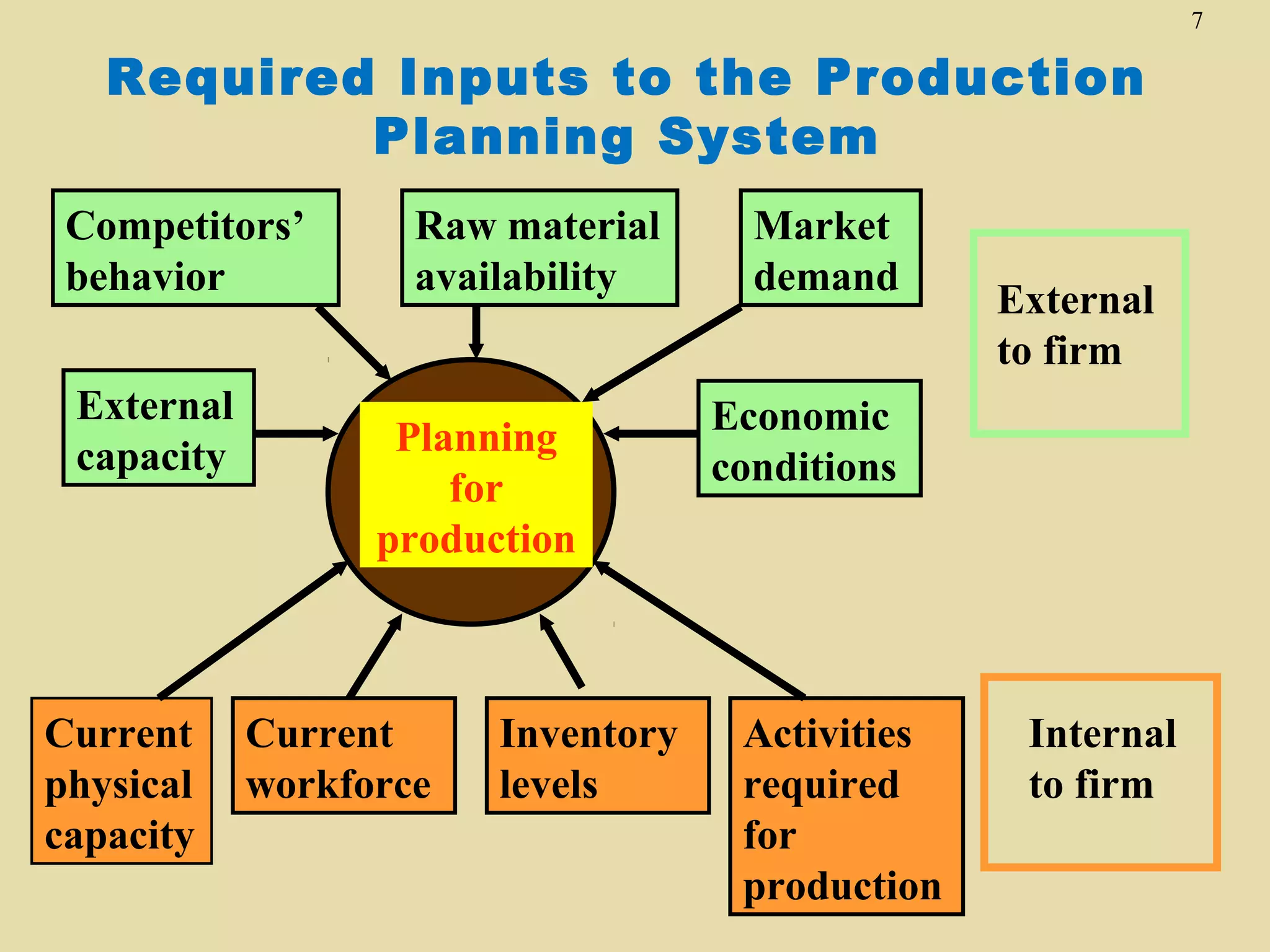

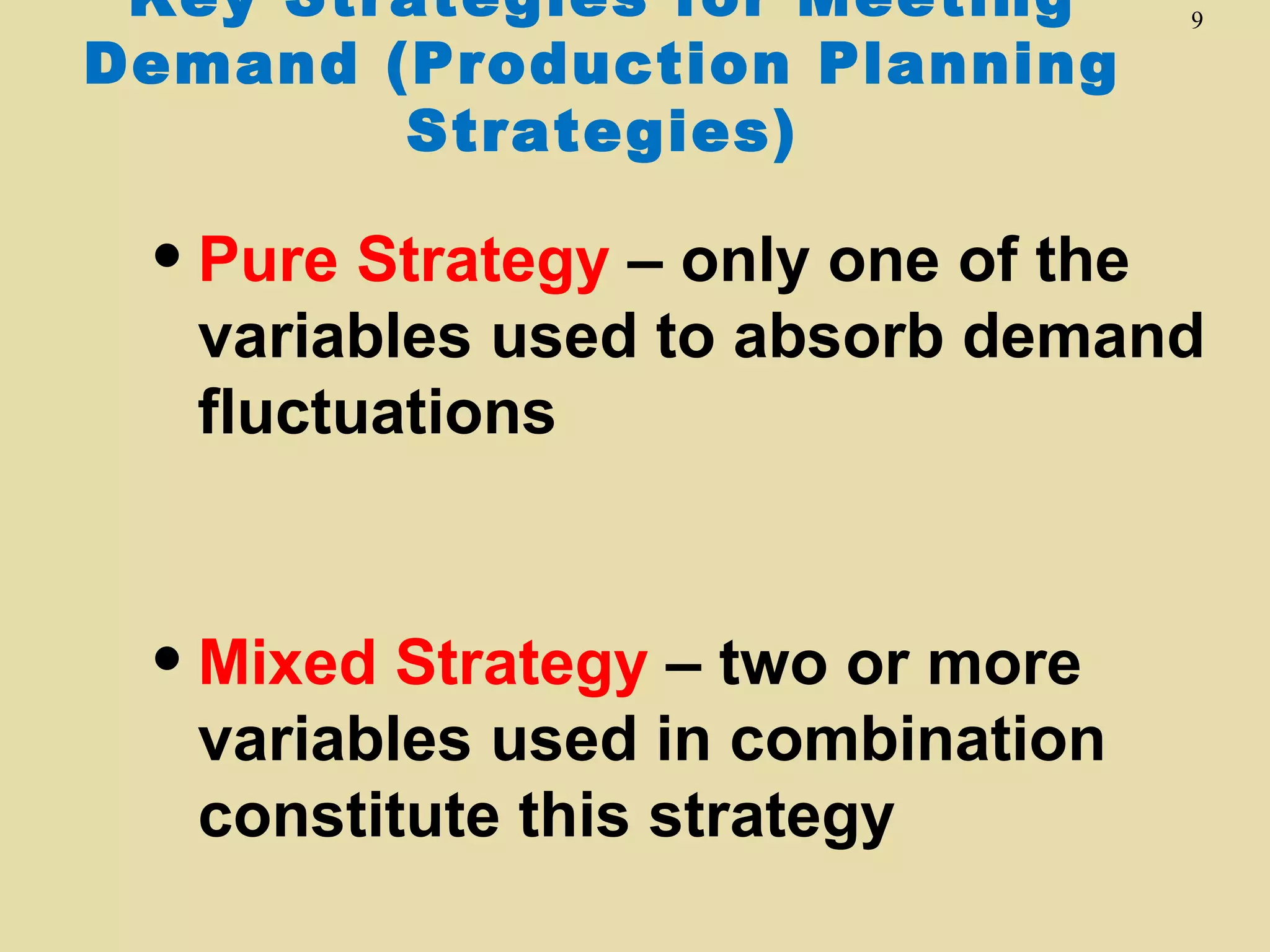

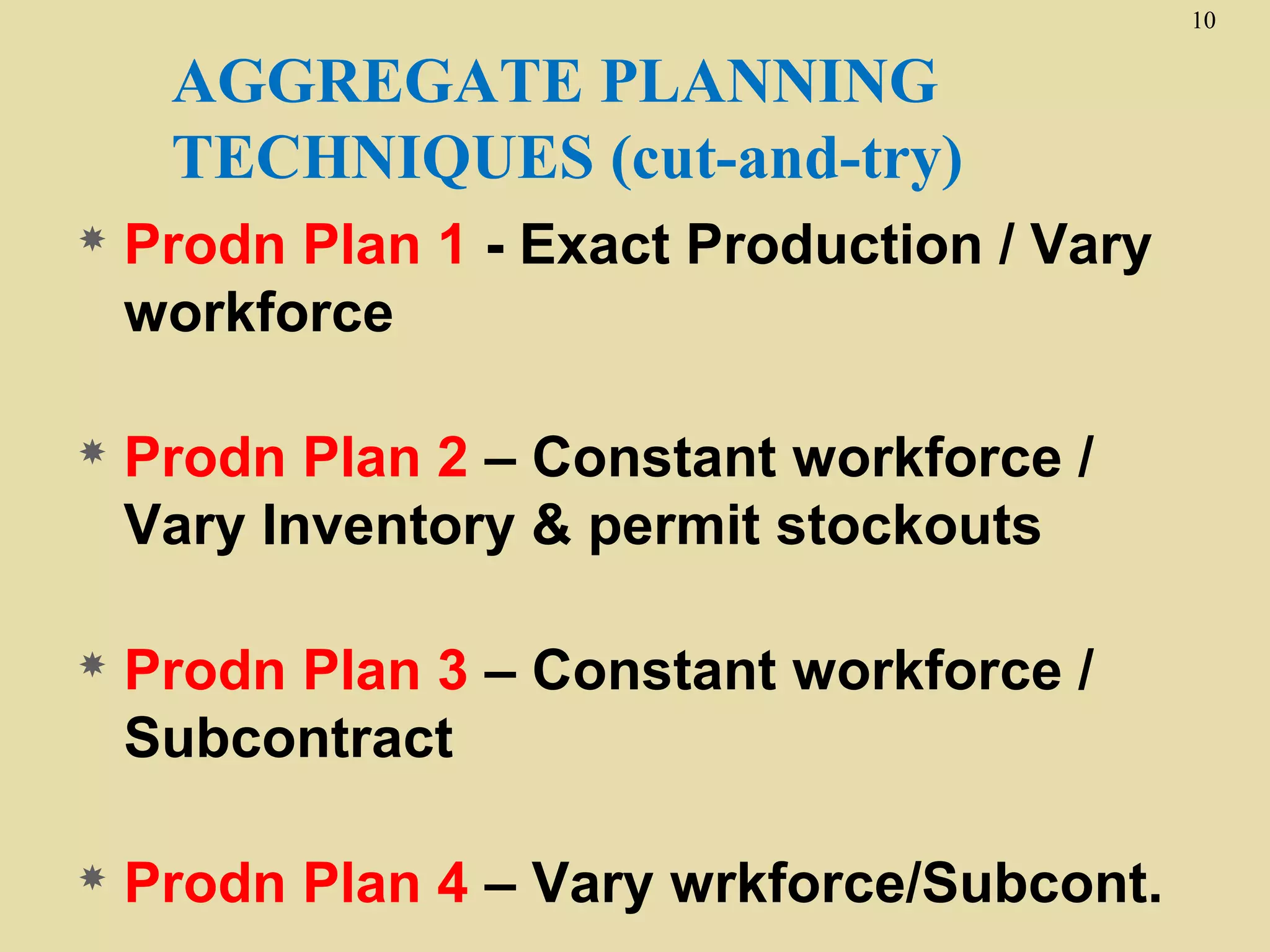

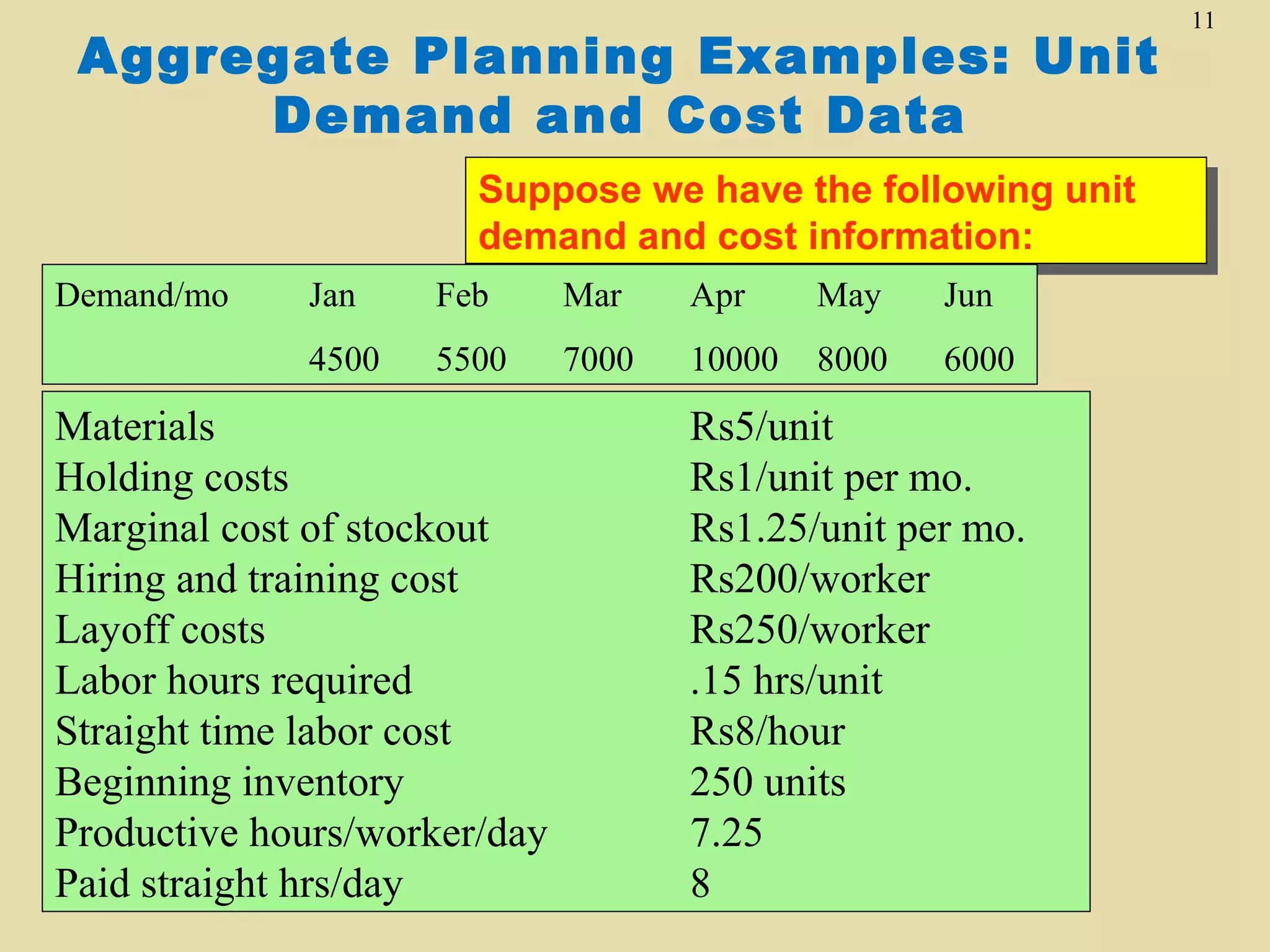

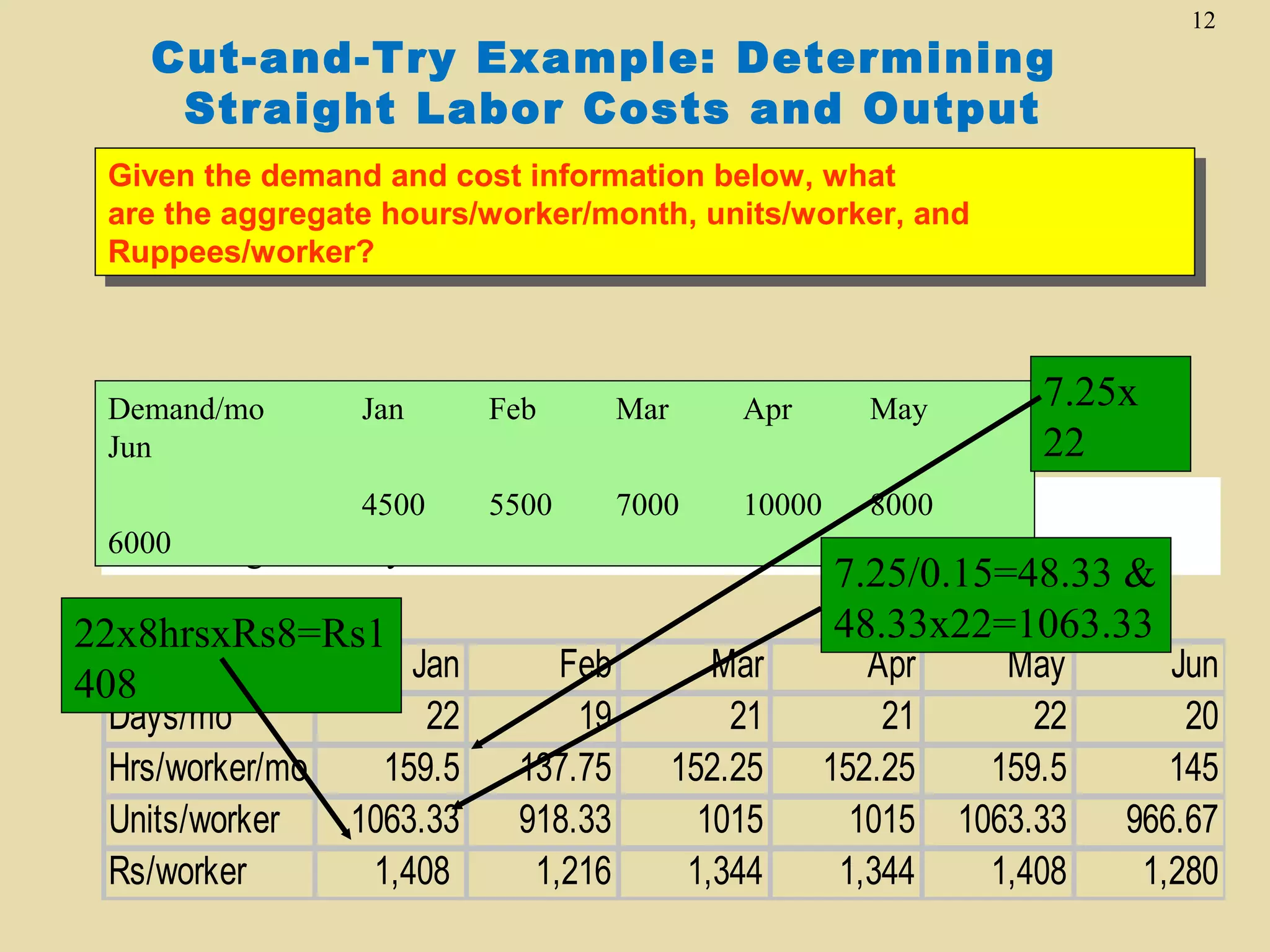

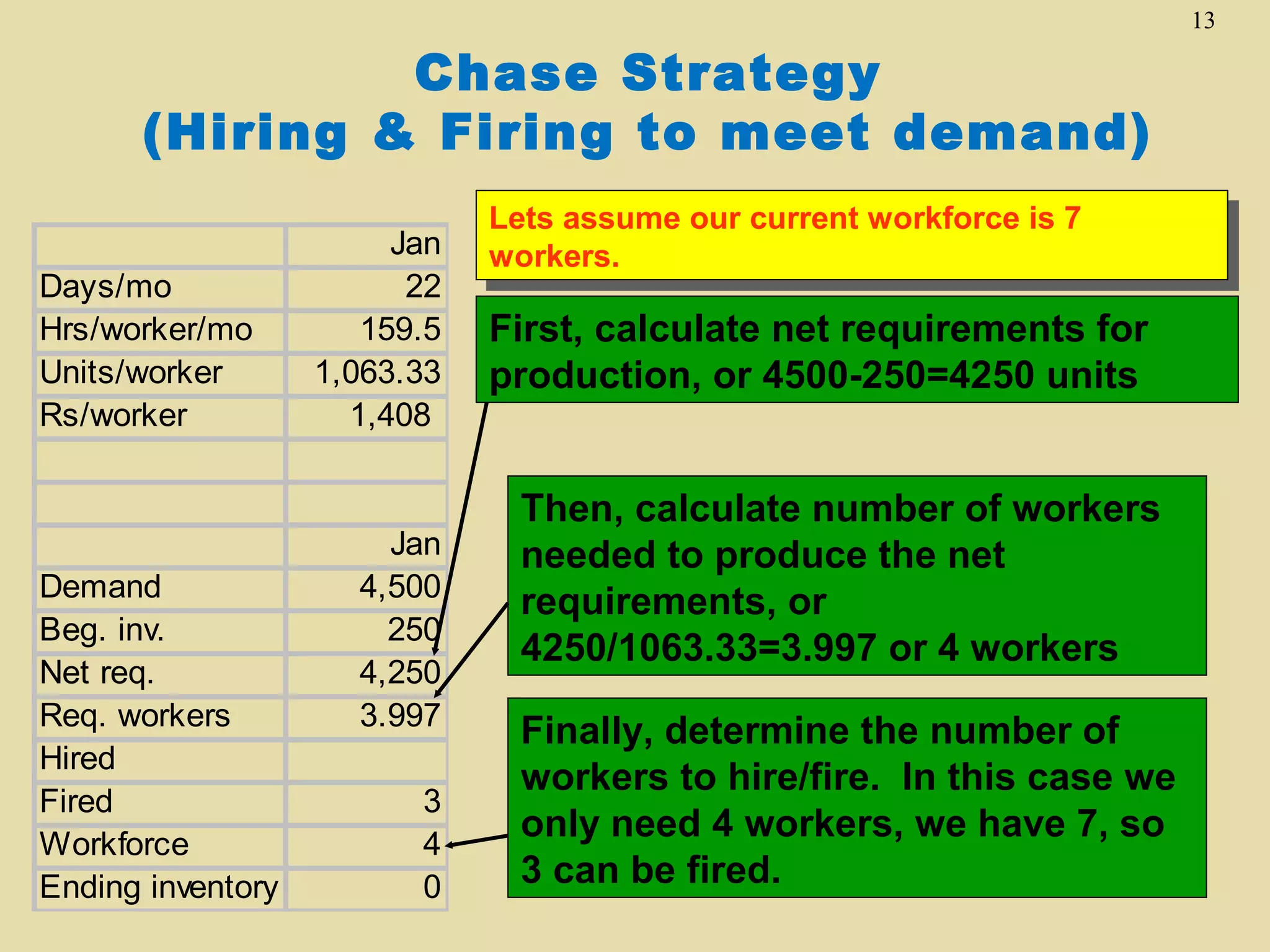

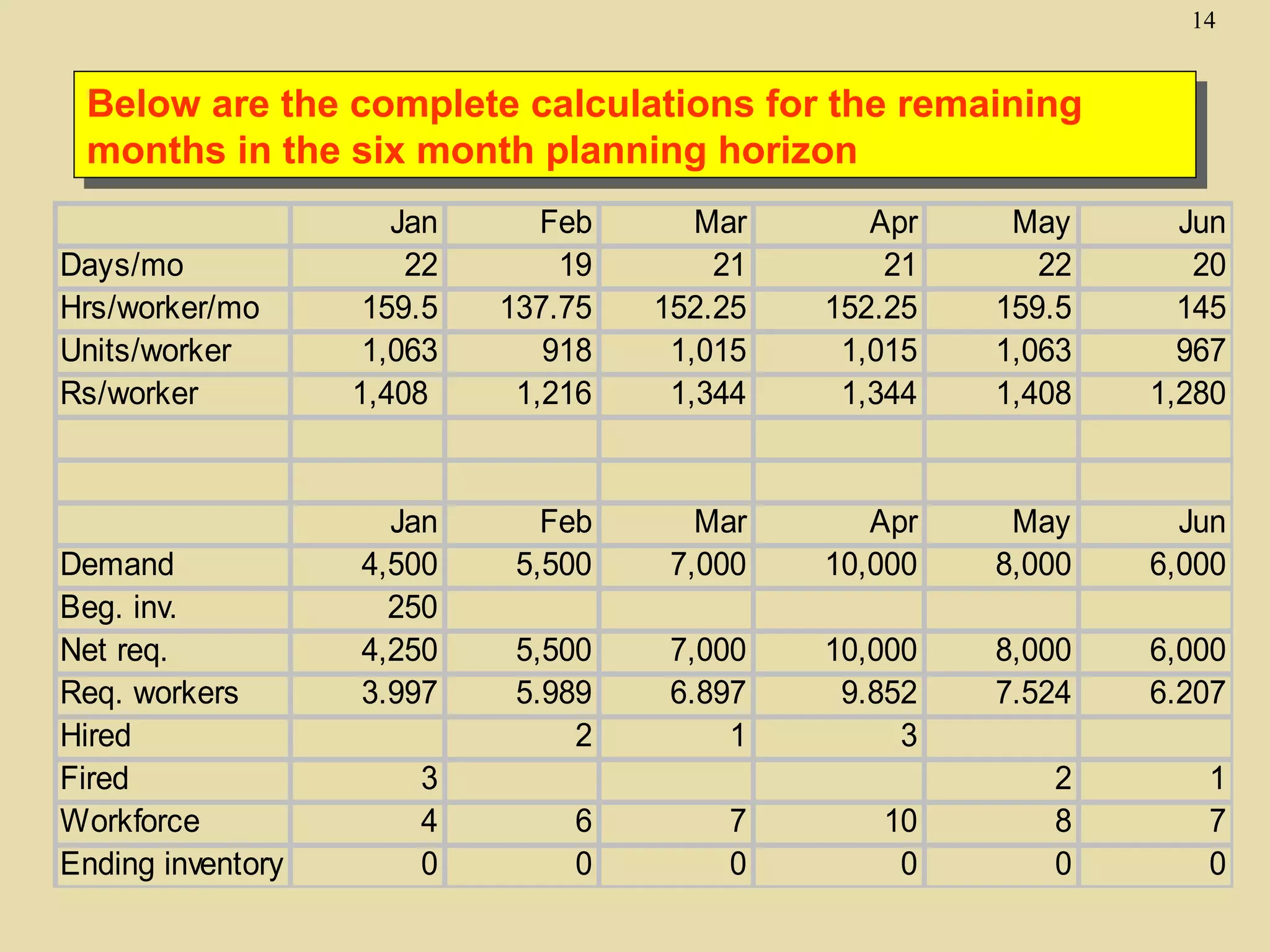

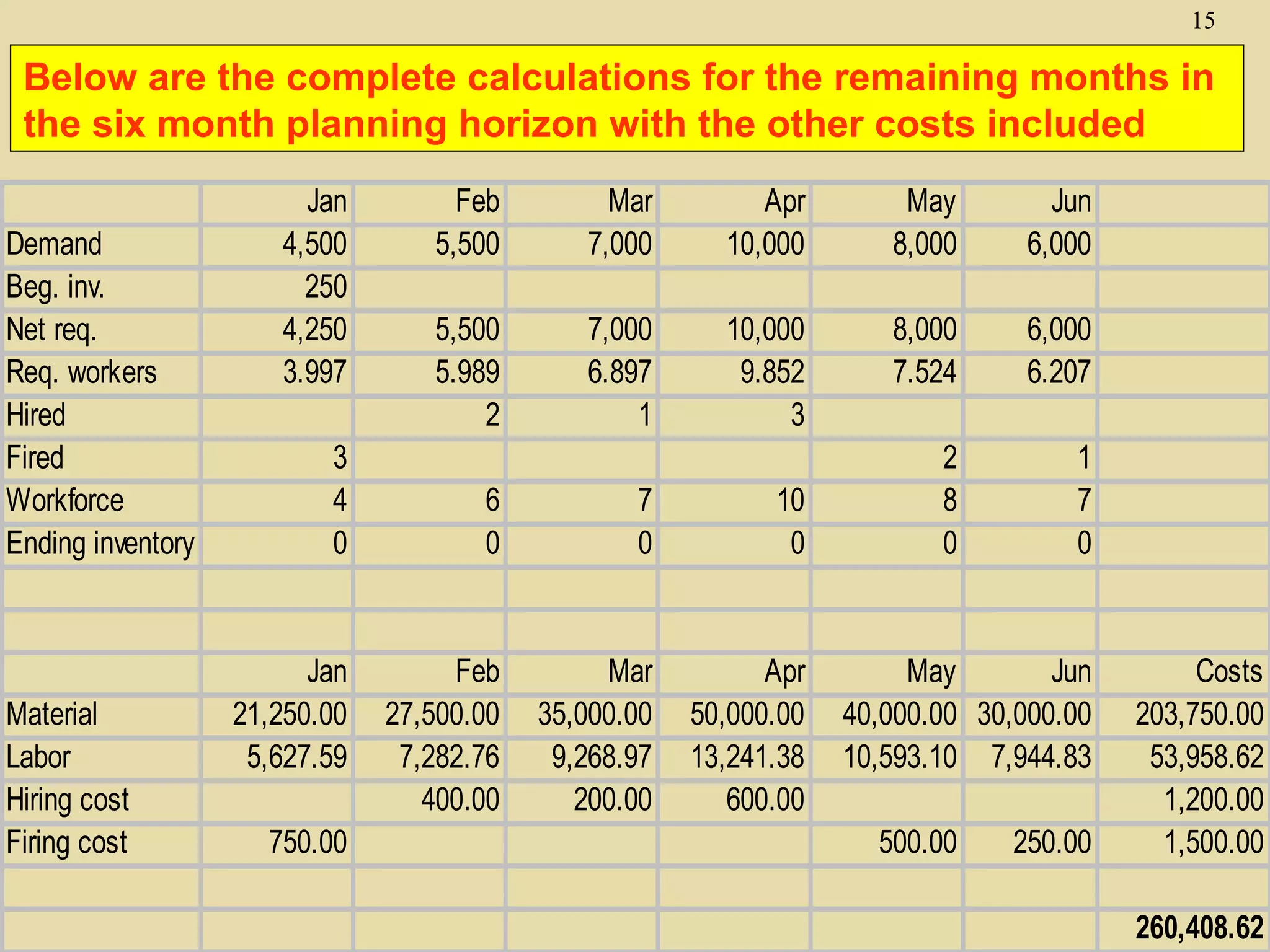

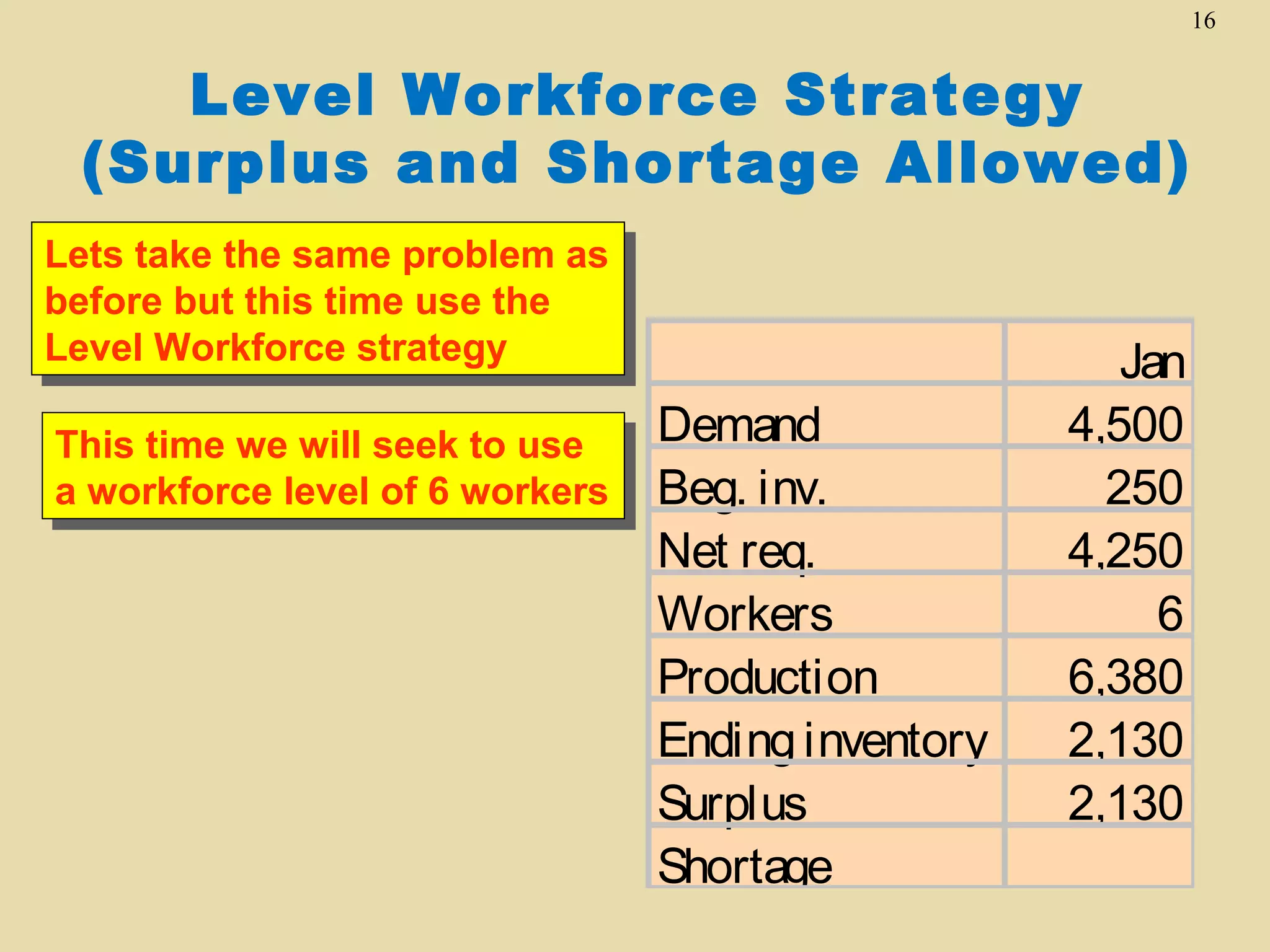

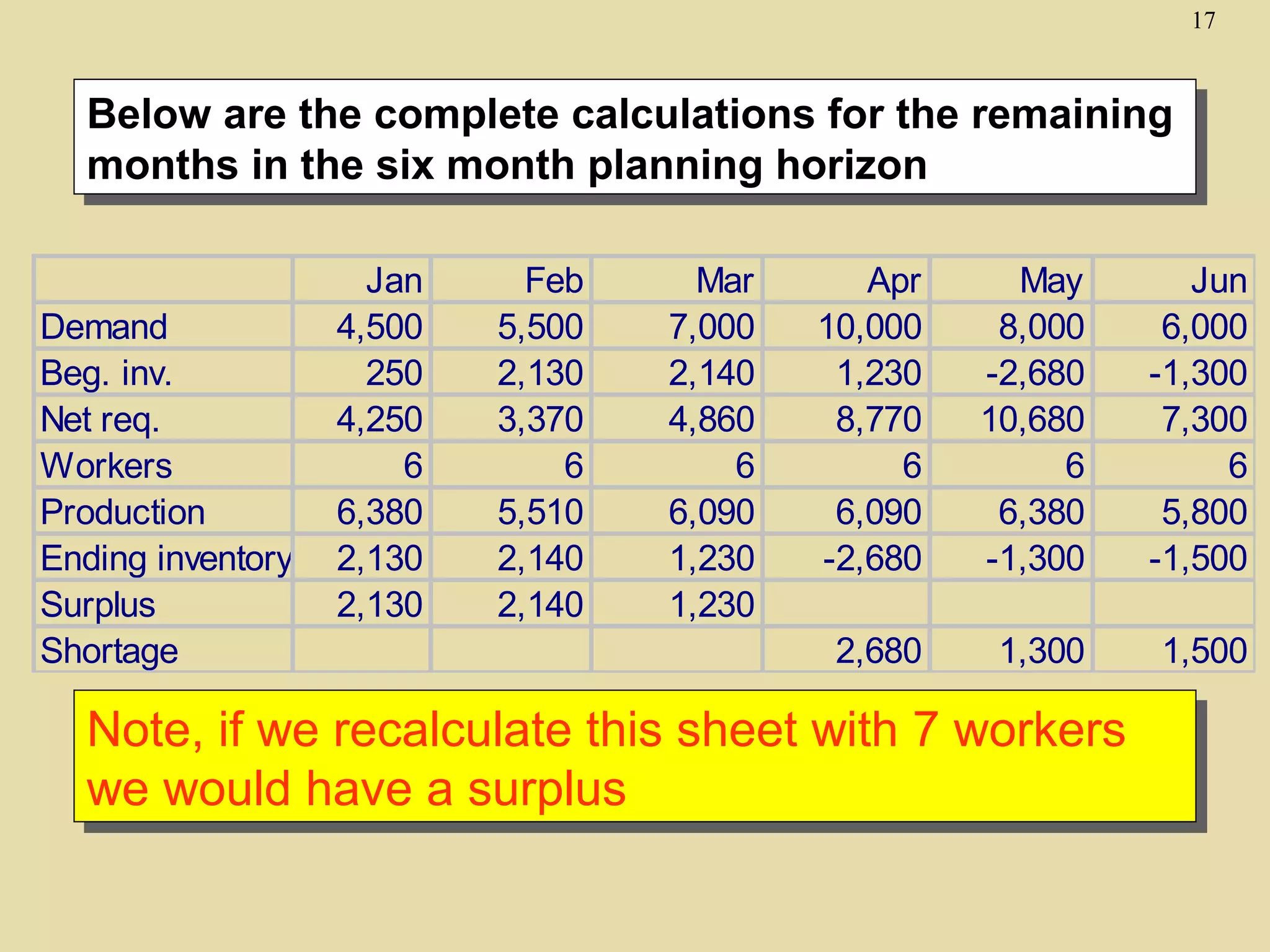

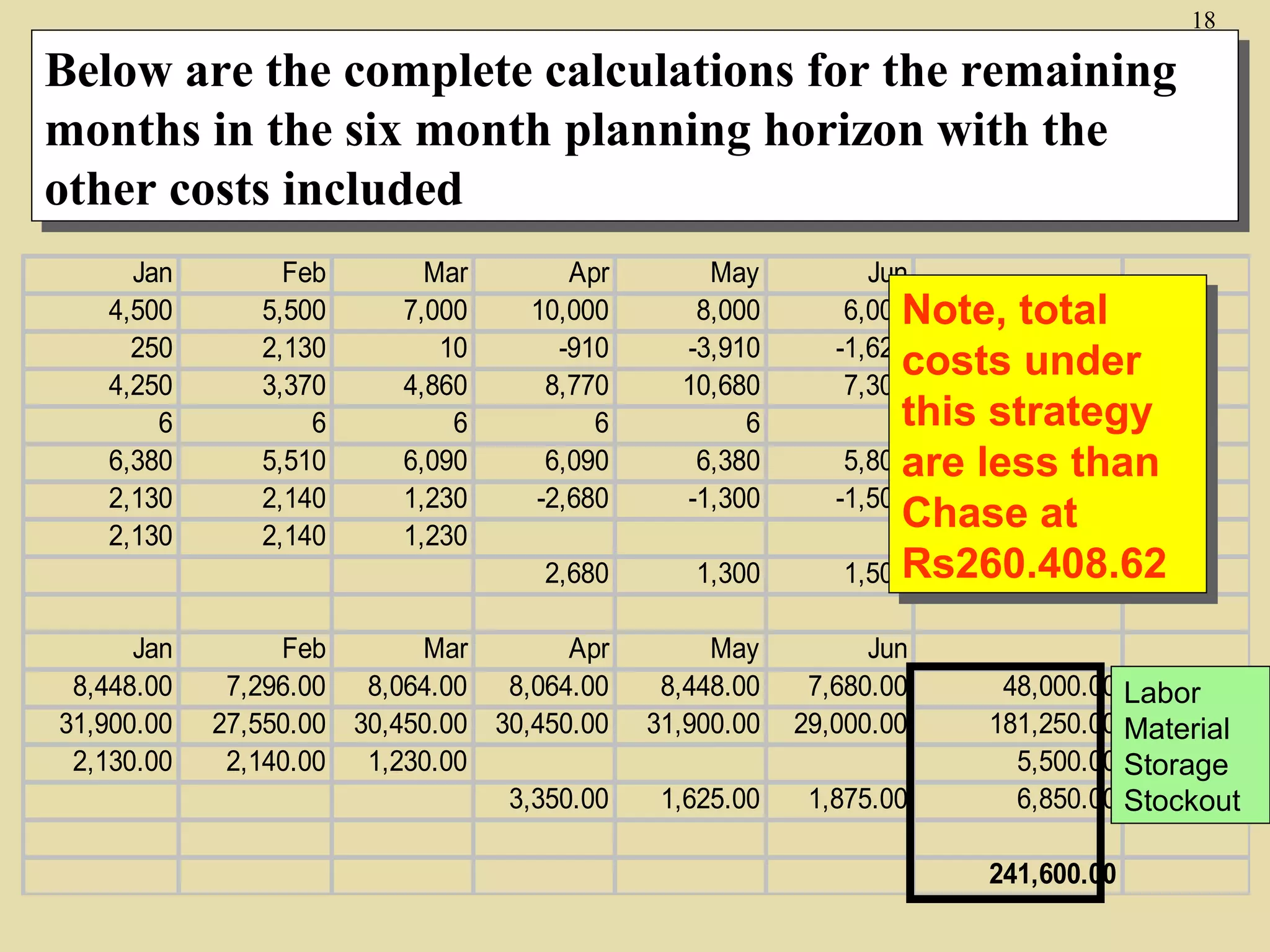

This document discusses aggregate sales and operations planning. It describes the objectives of sales and operations planning and the aggregate operations plan. It outlines the sales and operations planning process from long-range to short-range planning. It also discusses strategies for balancing aggregate demand and production capacity, such as the chase and level strategies. Finally, it provides an example of using a spreadsheet to calculate costs and workforce needs under the chase and level strategies.