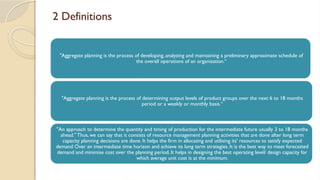

The document discusses aggregate planning and maintenance management within production and operations management, explaining the importance of aligning production capacity with demand forecasts over intermediate time horizons. It highlights various planning strategies, such as top-down and bottom-up approaches, and emphasizes the significance of maintenance management for ensuring operational efficiency, reliability, and cost control. Additionally, it outlines different types of maintenance, including breakdown, preventive, and routine maintenance, and their roles in maintaining equipment functionality.

![[3] Importance of Aggregate Plan

1) It helps in minimising costs and maximising profit.

2) It helps to maximise customer service by providing on time deliveries. It helps to adjust workforce

requirements, inventory requirements, machine capacity utilisation and thereby improving delivery

time.

3) It minimises investment in inventory. Excessive inventory leads to blockage of capital. However by

determining demand and summing up the demand for individual product, inventory levels could be

adjusted as per the aggregate demand for each time period.

4) It helps in maximising utilisation of plant and equipment by facilitating fully loaded facilities and

minimising over loading and under loading.

5) It helps in minimising changes in work force levels. Due to fluctuating workforce levels there might be

loss of labour productivity, increasing cost and time needed for training new employees. But, aggregate

planning helps in appropriate utilisation of workforce by determining overtime or undertime hiring or

lay off or subcontracting or outsourcing.

6) It helps in minimizing changes in production rates by orderly and systematic transition of production

capacity to meet peaks and valleys of expected customer demand. Frequent changes in production

rates may cause difficulty in coordinating material procurement and may require rebalancing of line.](https://image.slidesharecdn.com/unit-3aggregateplanningandmaintenancemanagement-250201140659-4903c654/85/UNIT-3-AGGREGATE-PLANNING-AND-MAINTENANCE-MANAGEMENT-pptx-6-320.jpg)