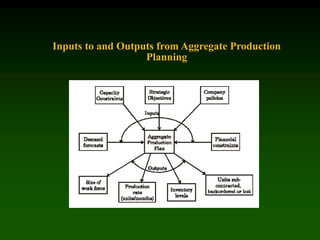

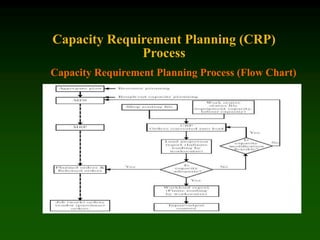

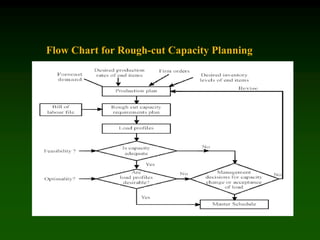

This document discusses aggregate planning and capacity planning. Aggregate planning involves determining optimal production levels over the next 6-18 months to balance objectives like customer service, workforce stability and costs. Capacity planning determines production capacity needs to meet demand forecasts. It evaluates capacity alternatives and selects plans that satisfy demand at lowest cost. Key steps are determining demand forecasts, transforming demand into resource needs, identifying policies, developing alternative plans and selecting the optimal plan.