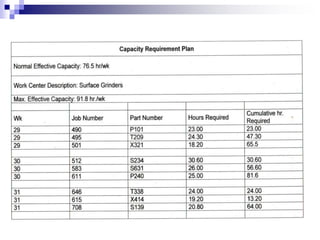

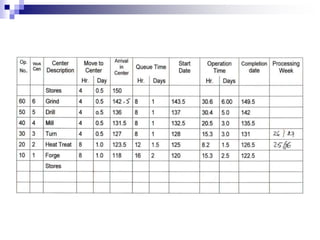

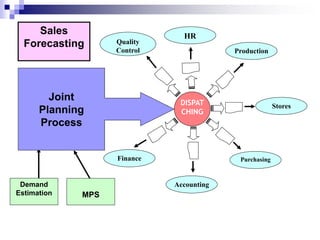

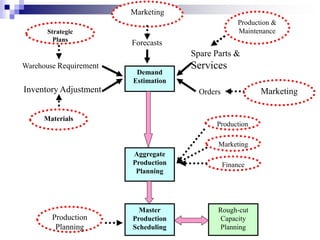

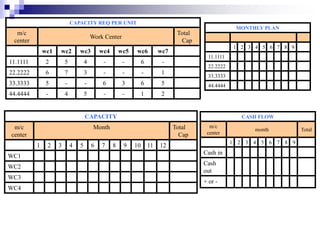

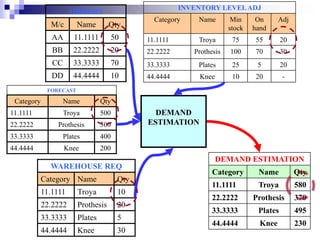

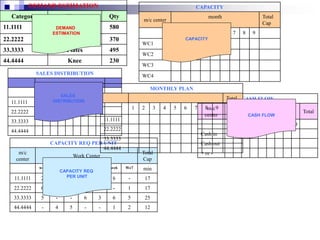

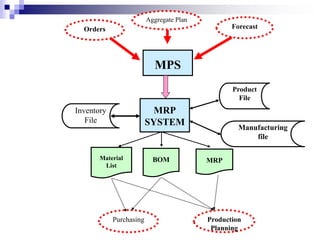

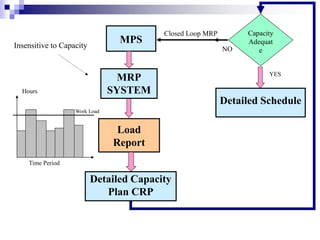

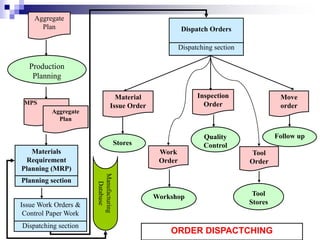

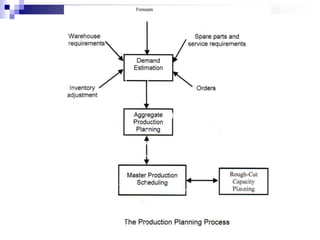

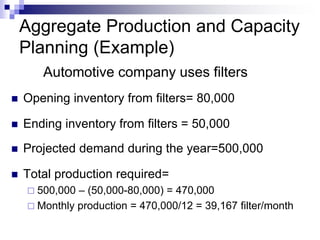

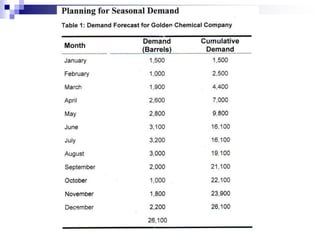

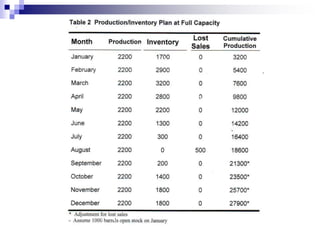

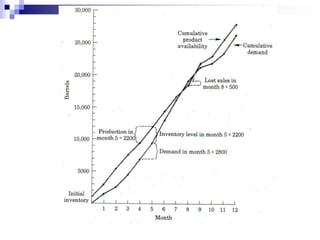

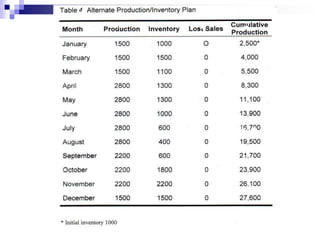

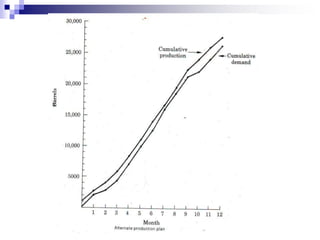

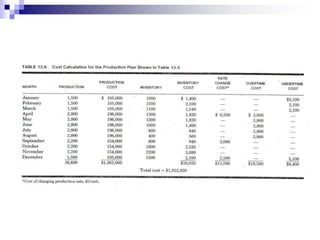

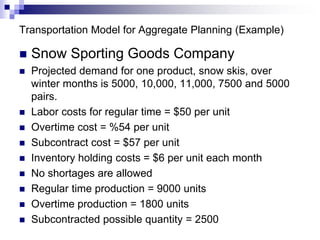

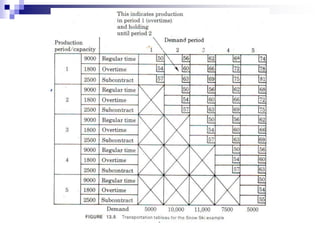

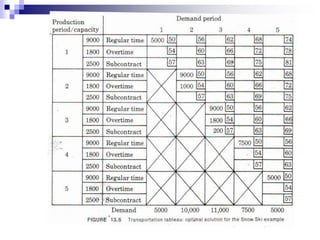

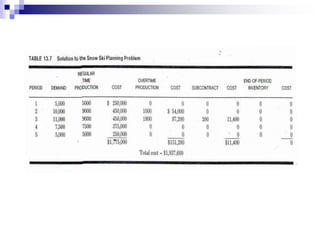

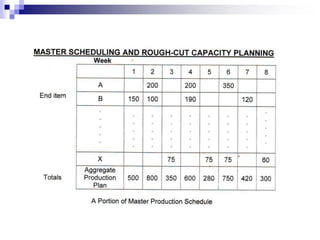

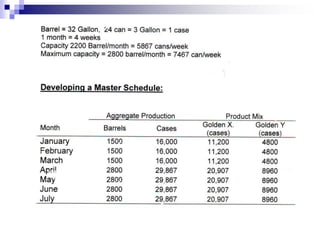

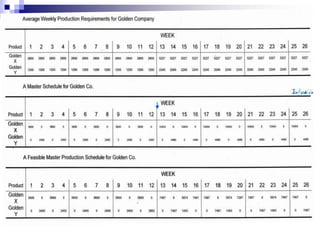

The document discusses aggregate production planning and capacity planning. It describes aggregate production planning as developing monthly or quarterly production requirements to meet demand estimates while considering gross capacity limitations. If capacity is insufficient, intermediate adjustments may be needed. The master production schedule (MPS) disaggregates the production plan into weekly product requirements over 6-12 months and is used by operations to plan procurement, production, and assembly. The rough cut capacity plan analyzes the MPS to identify potential bottlenecks.