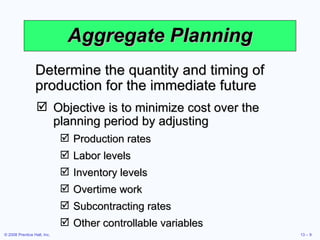

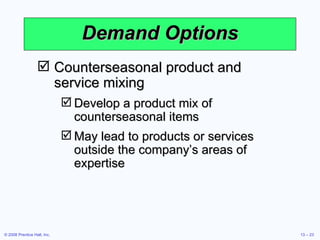

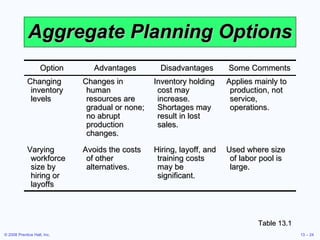

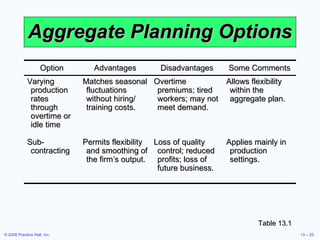

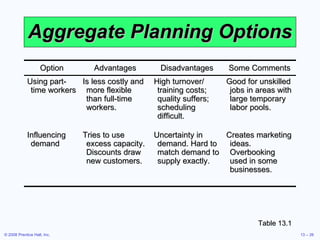

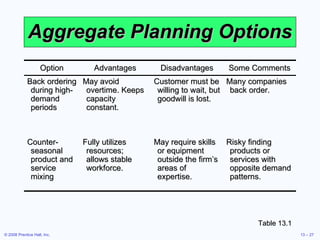

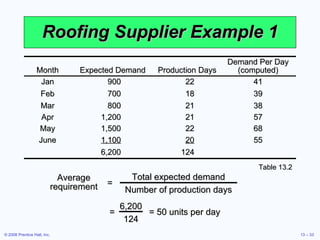

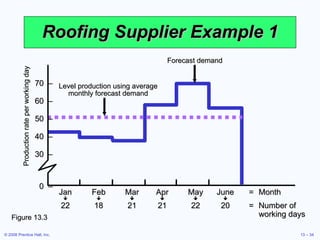

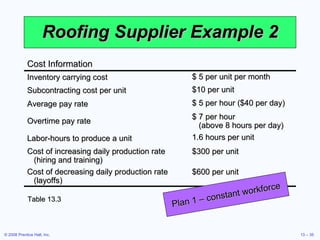

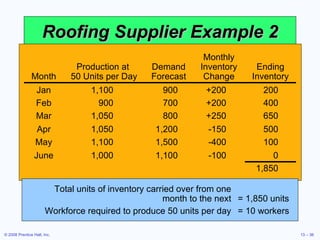

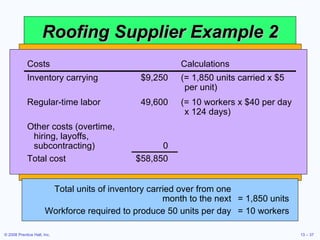

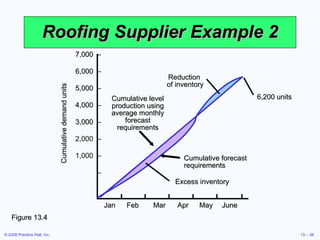

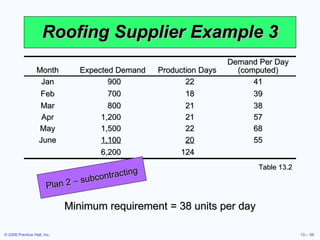

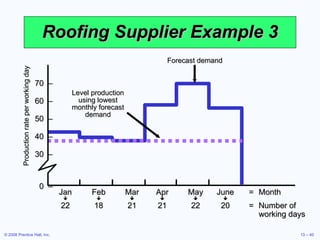

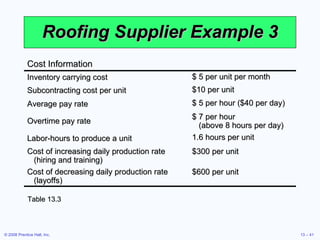

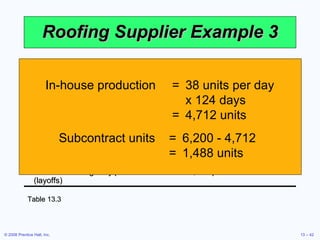

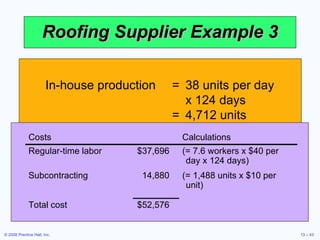

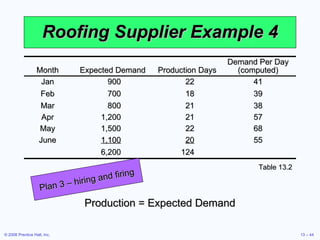

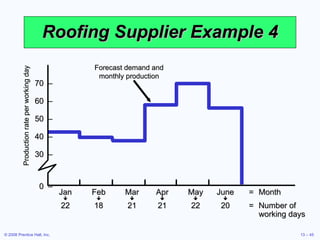

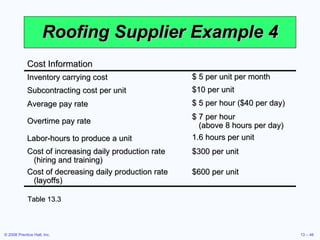

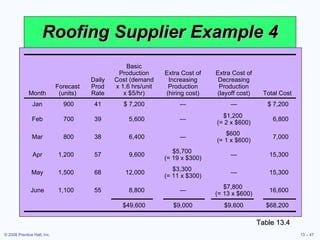

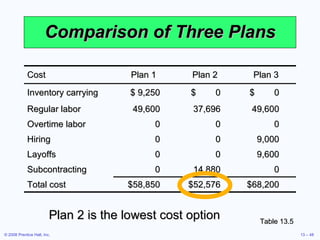

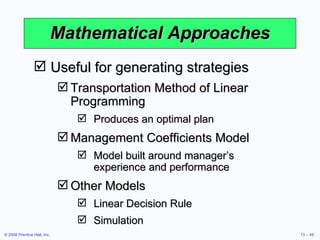

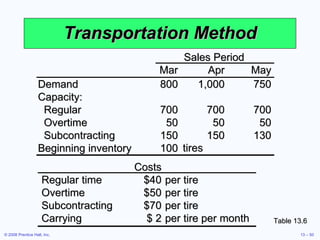

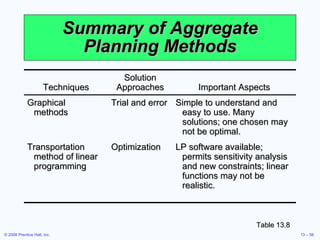

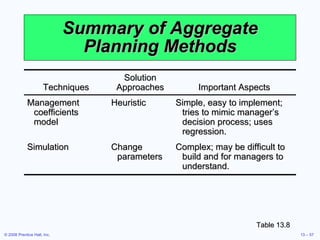

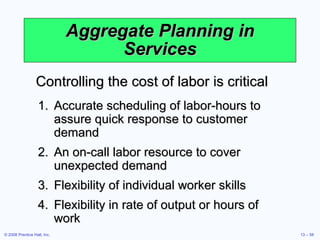

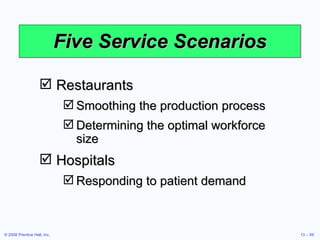

The document provides an overview of operations management concepts related to aggregate planning. It discusses aggregate planning strategies like adjusting production rates, workforce levels, and inventory levels. It provides examples of using graphical and mathematical methods to develop aggregate plans for a roofing supplier. Different planning options are evaluated like maintaining a constant workforce, subcontracting, and hiring/firing to match production to fluctuating demand forecasts.