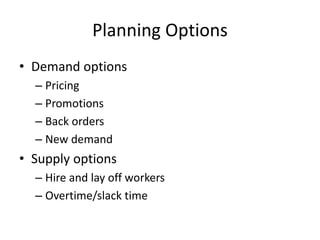

This document discusses aggregate planning, which involves determining production levels for the intermediate future of 6-18 months. Aggregate planning begins with forecasting demand and adjusting production rates, staffing levels, and inventory levels. It requires input from various functional areas regarding capacity, customer needs, demand forecasts, suppliers, and resources. The objectives of aggregate planning are to meet demand, provide stable work and customer service levels, and develop an economic strategy. It aims to minimize costs and inventory while maximizing profit, customer service, and plant utilization.