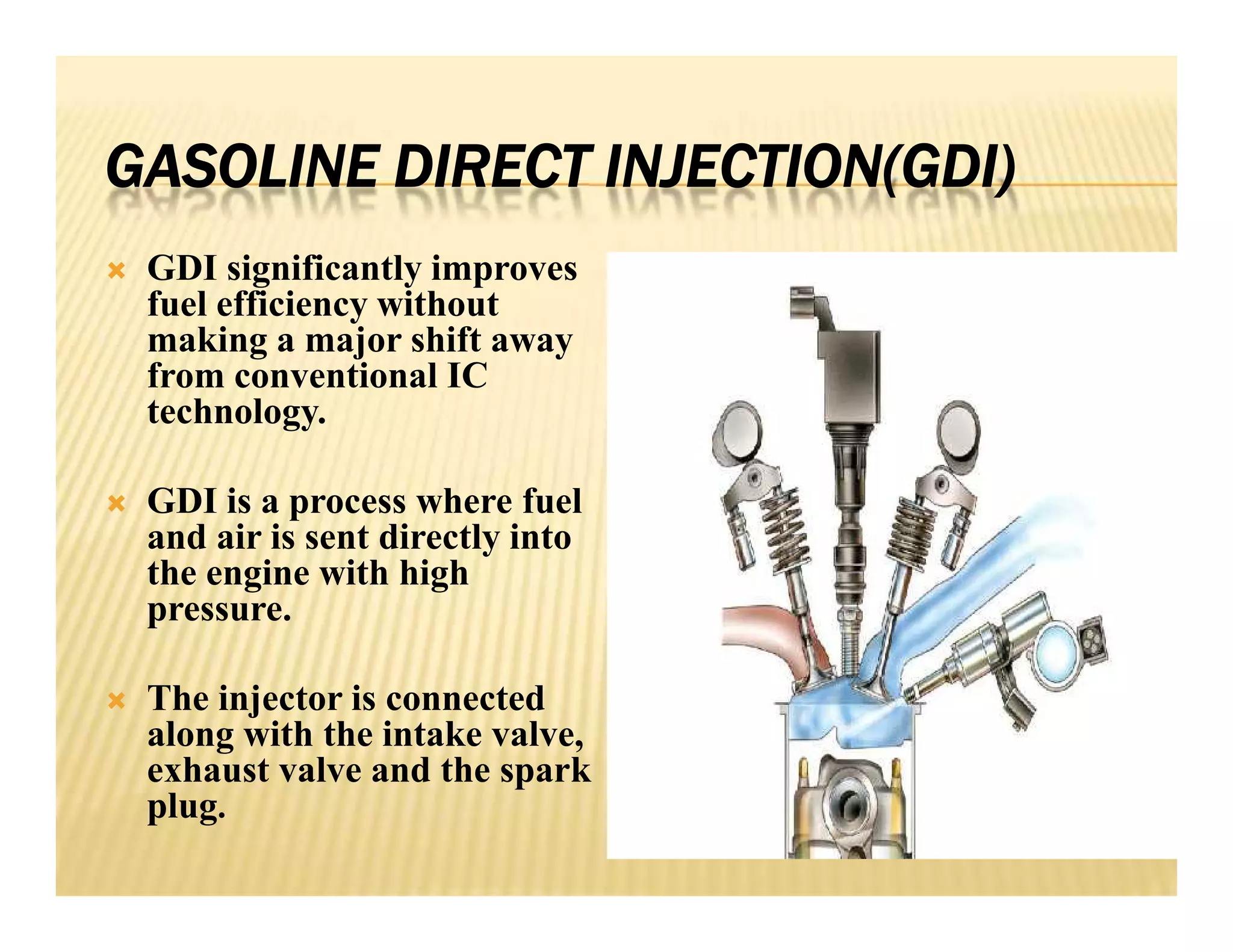

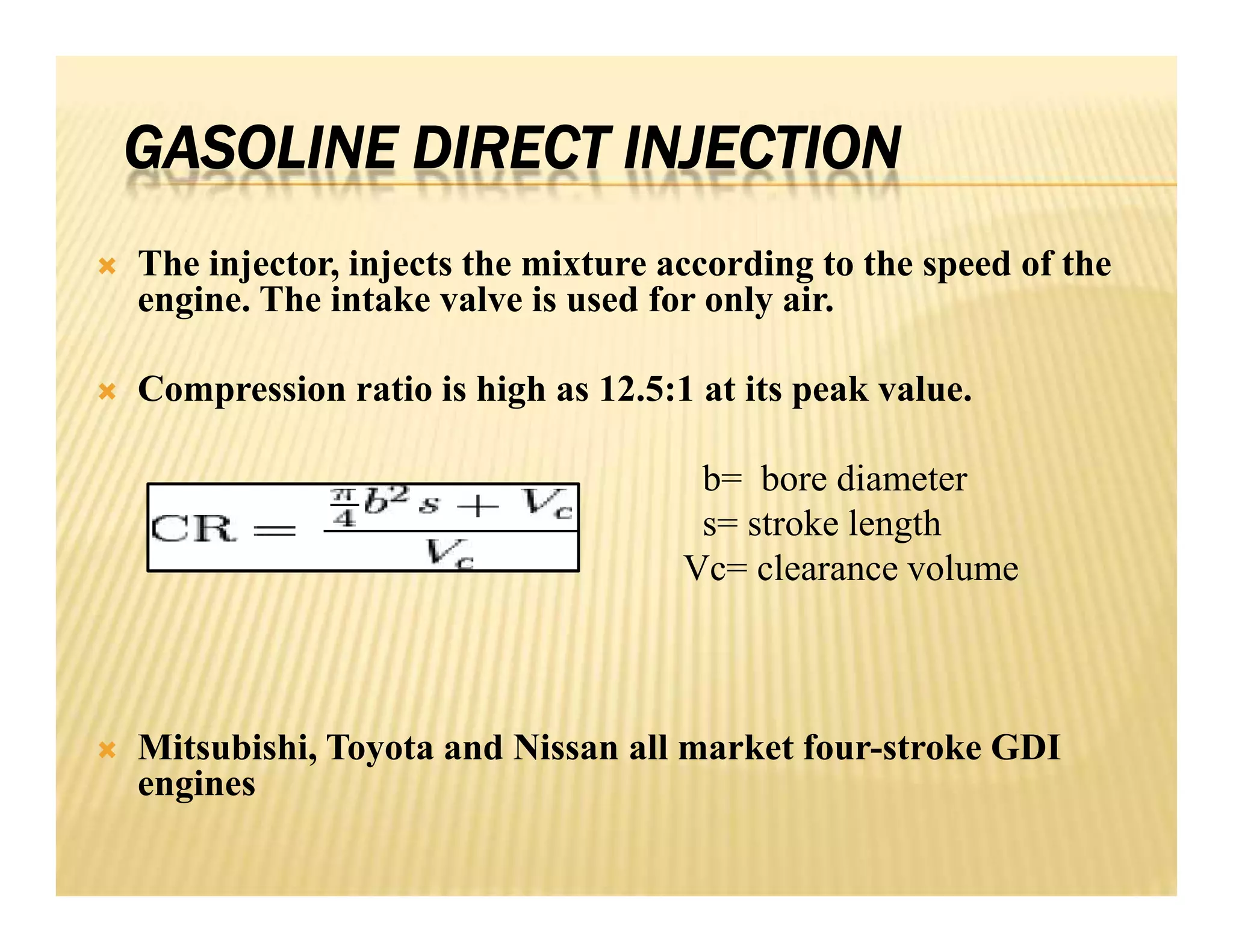

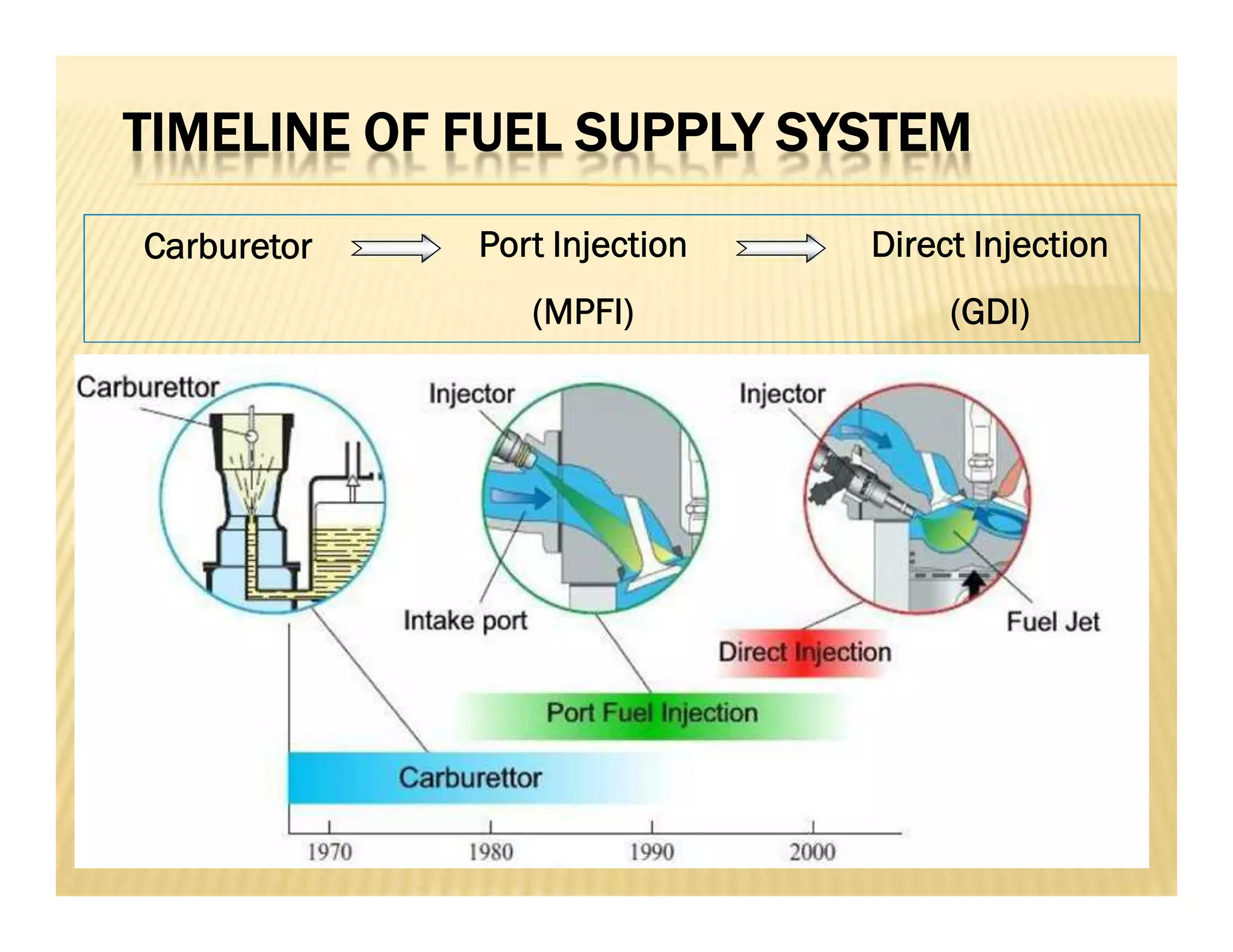

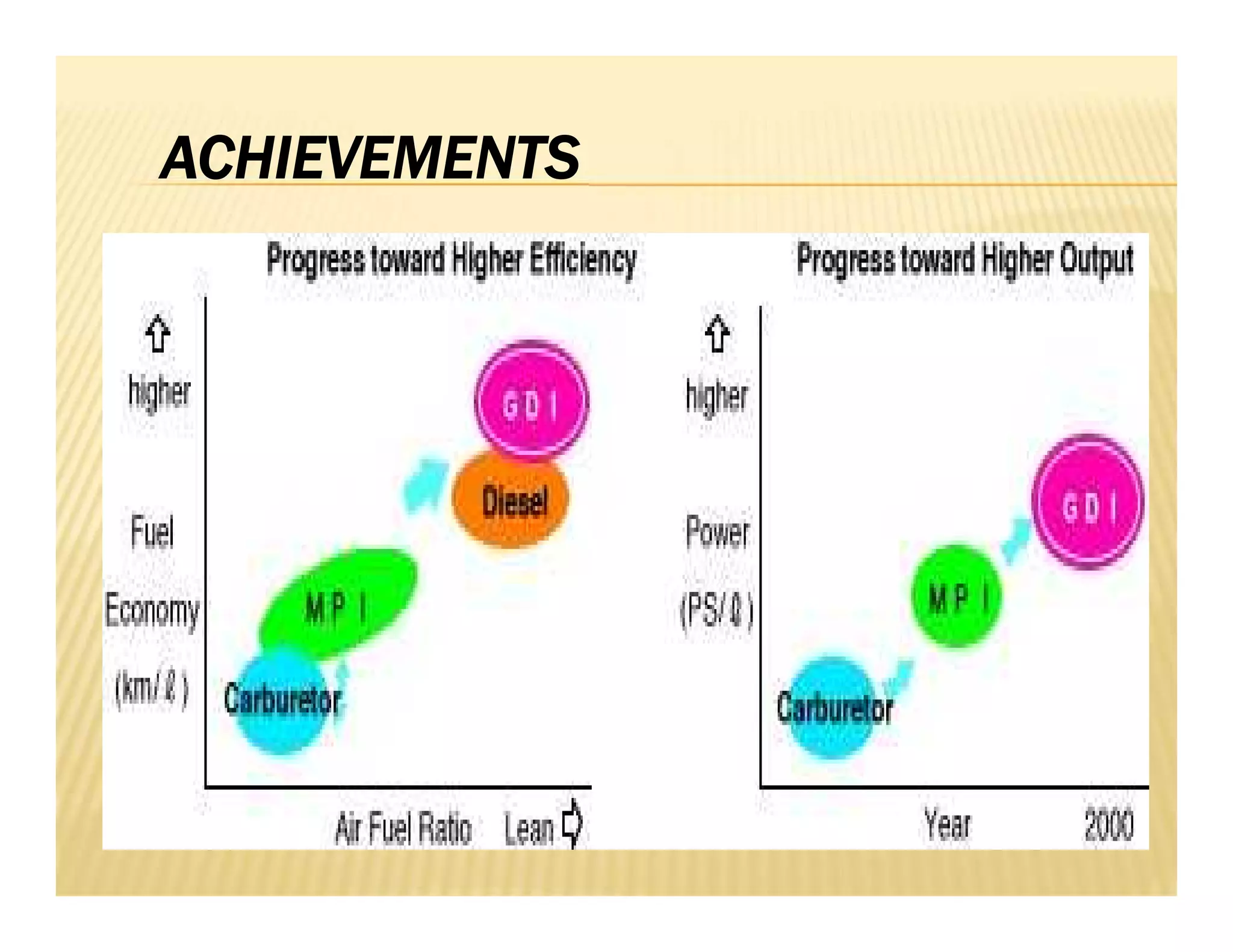

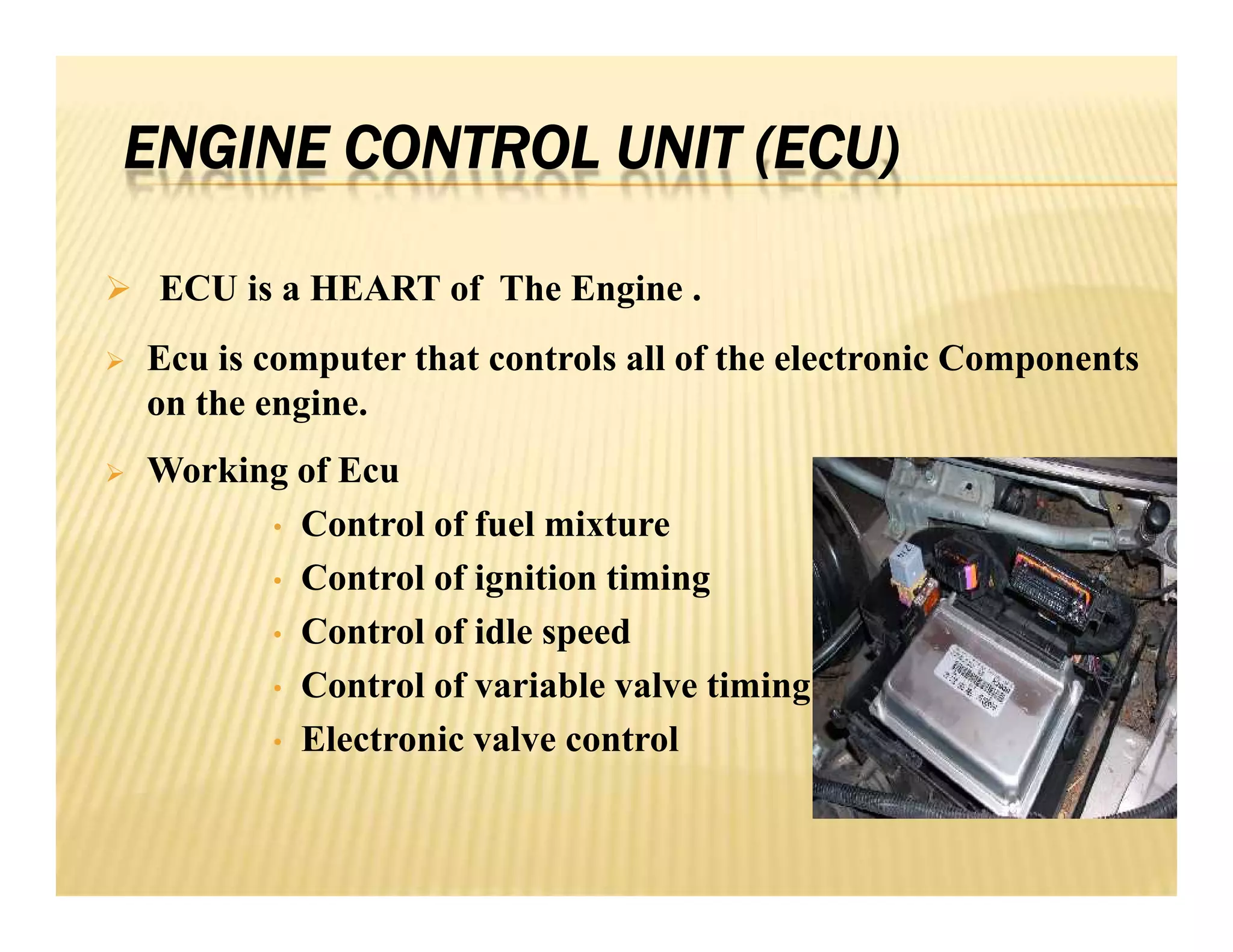

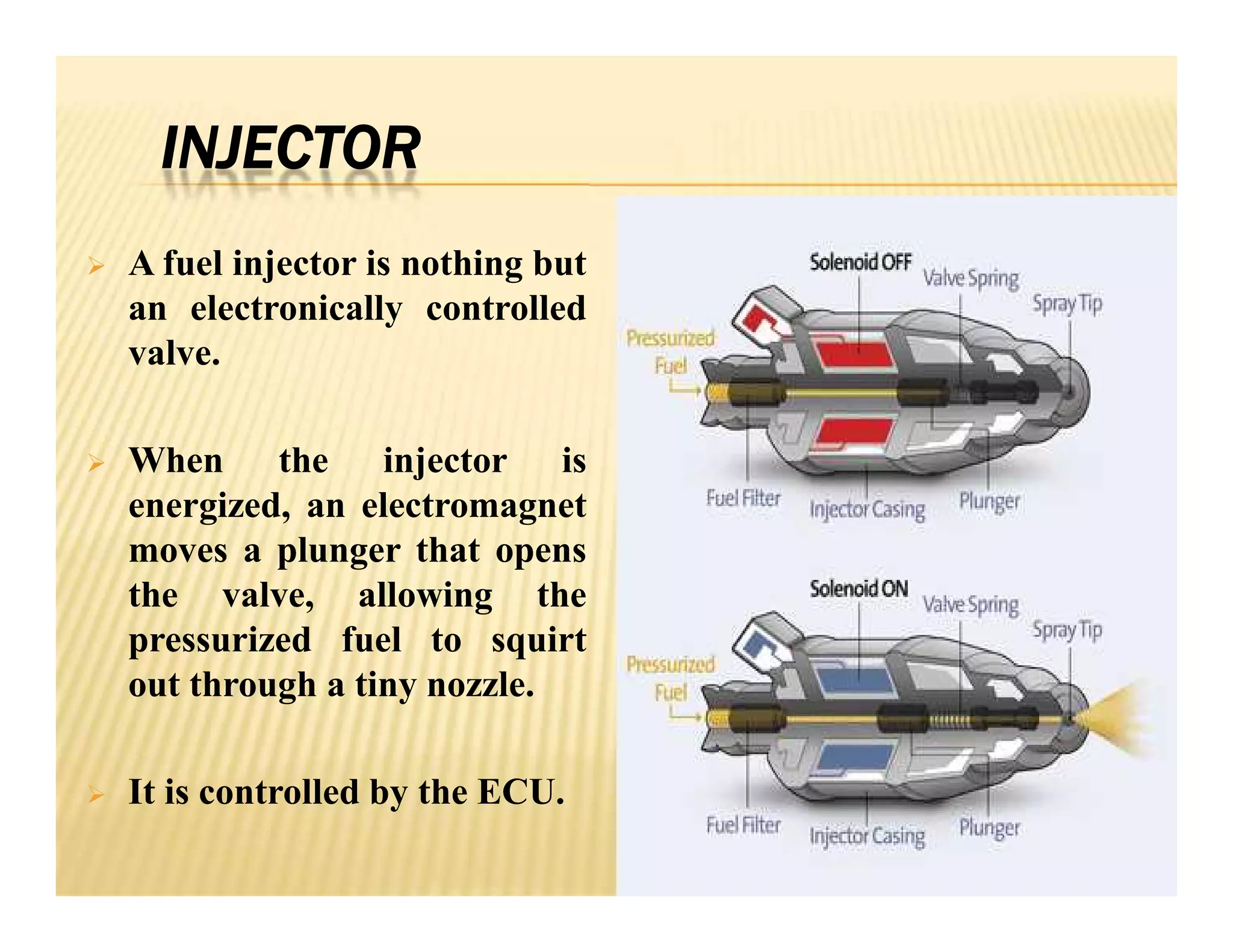

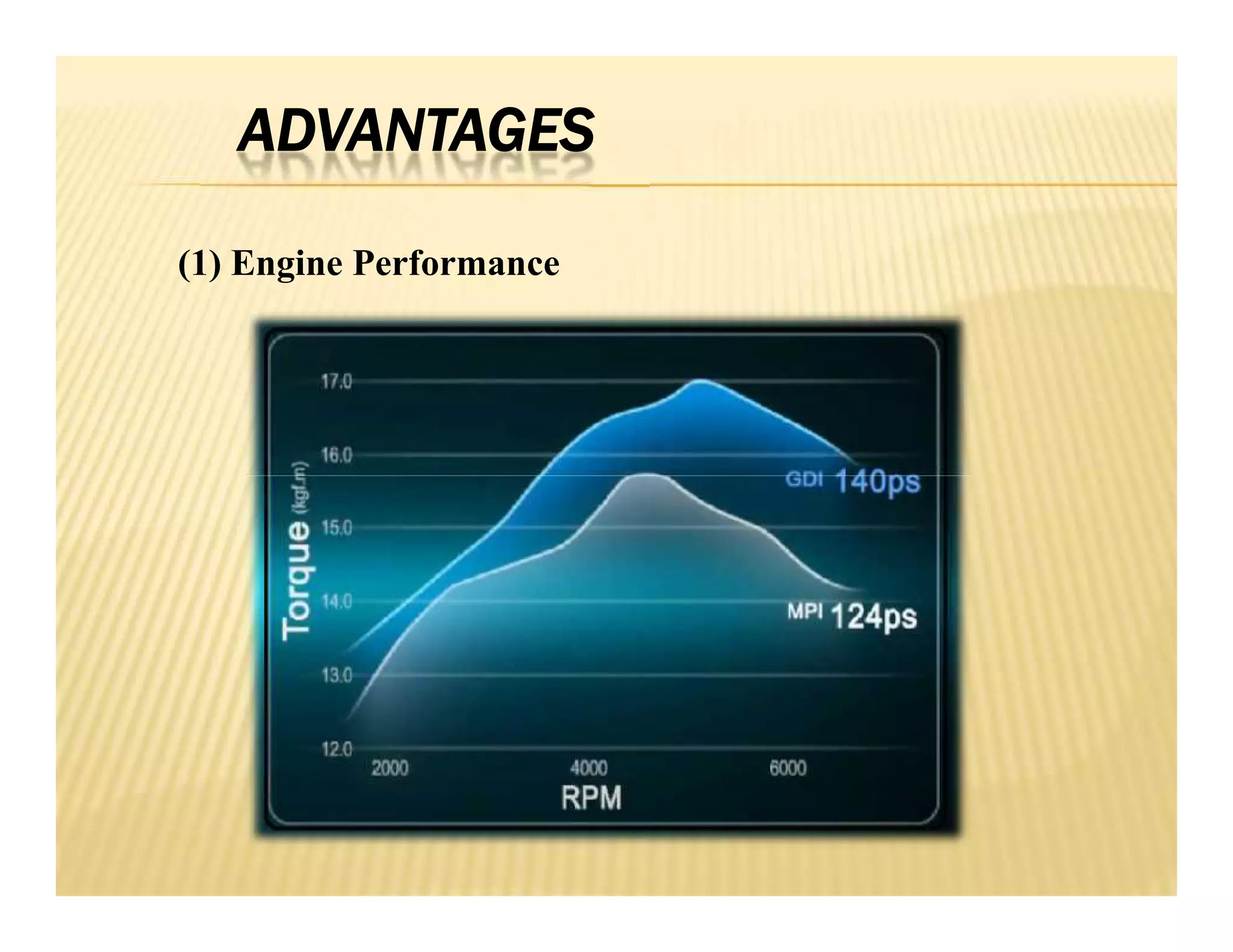

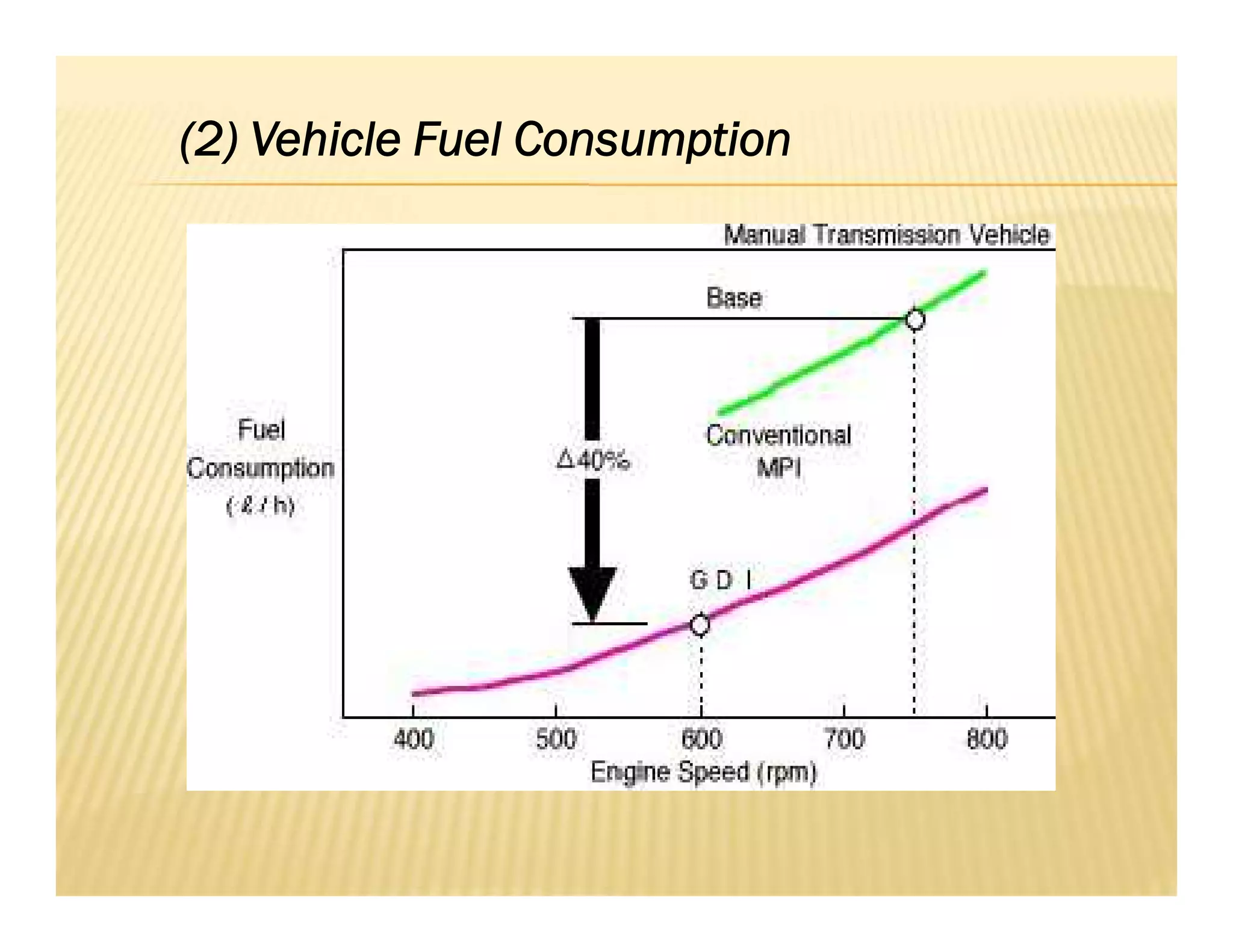

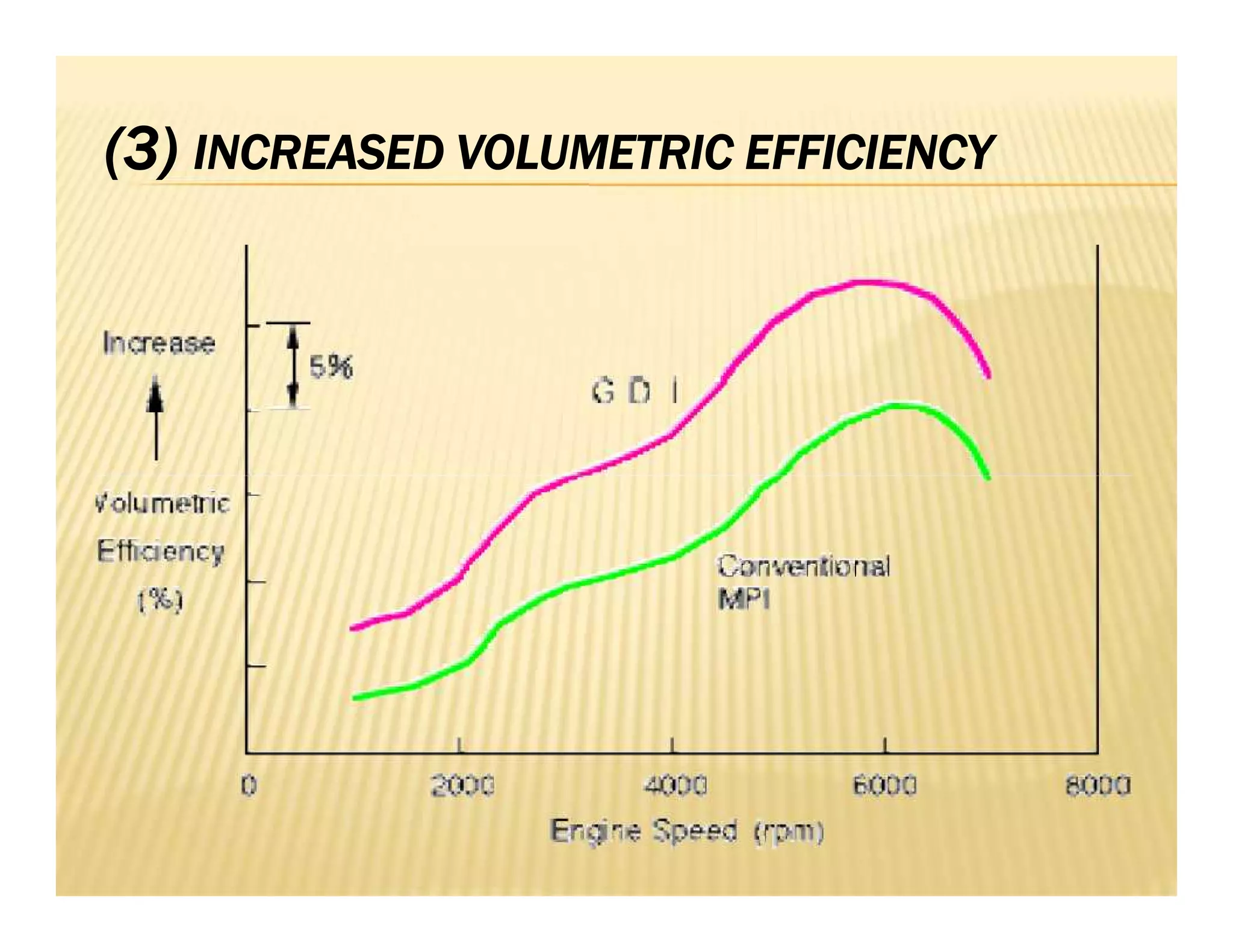

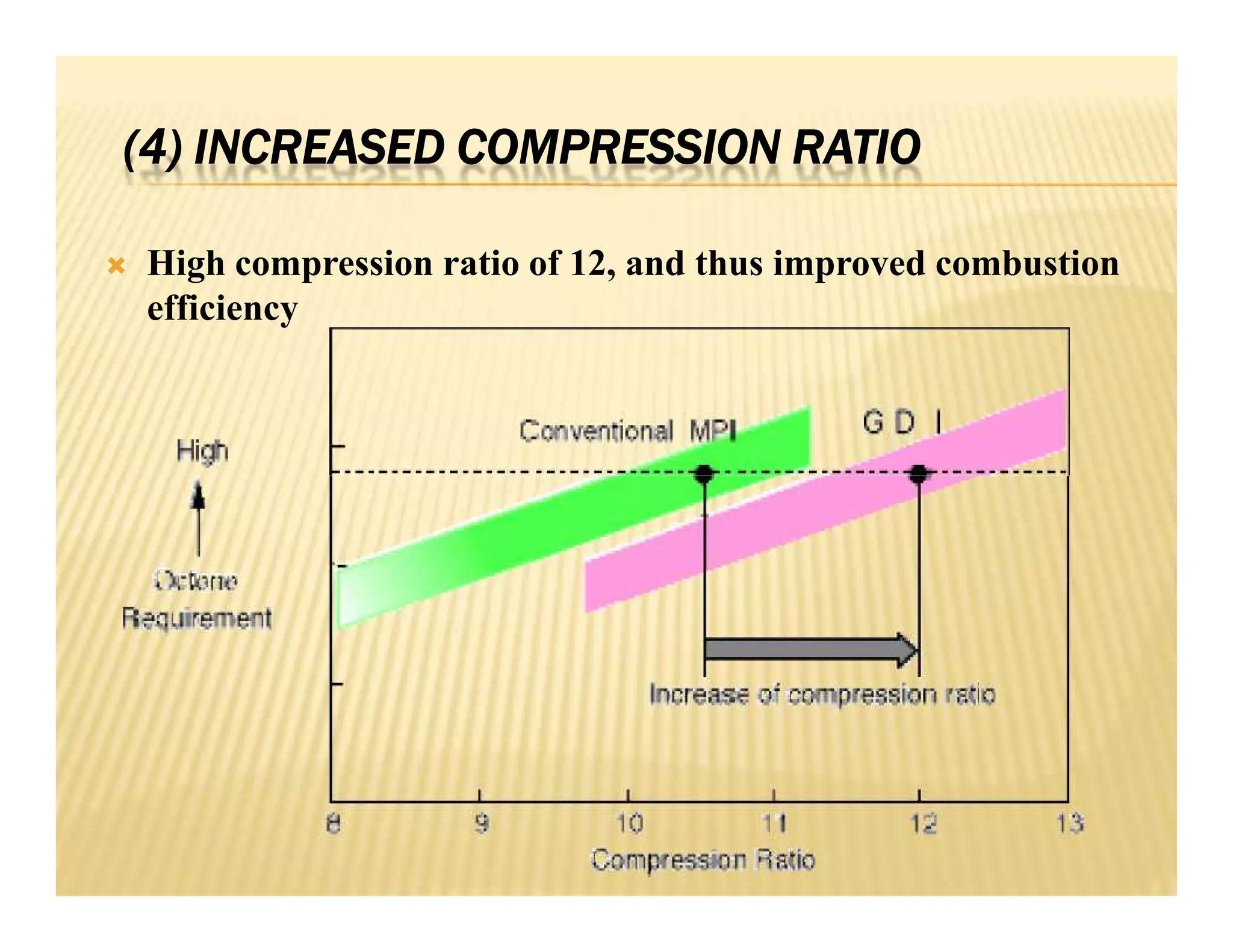

The document discusses gasoline direct injection (GDI), which improves fuel efficiency without significantly changing conventional internal combustion engine technology. GDI involves sending pressurized fuel directly into the combustion chamber rather than mixing it with air in the intake manifold. This allows for a higher compression ratio and more precise fuel delivery. GDI provides benefits like reduced fuel consumption and emissions compared to port fuel injection systems, but also presents challenges such as increased complexity, cost, and risk of deposits. Major automakers now offer vehicles with GDI engines.