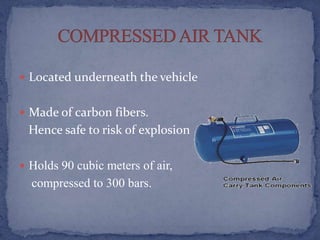

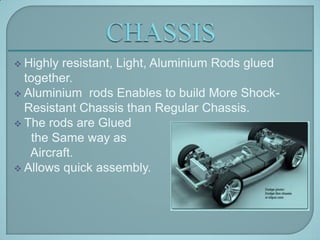

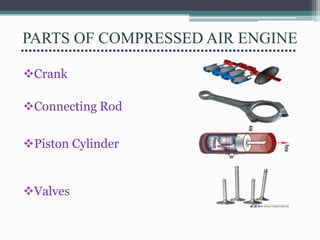

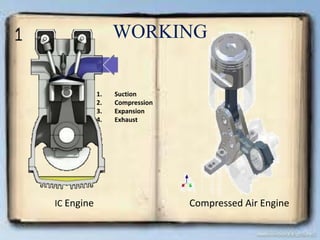

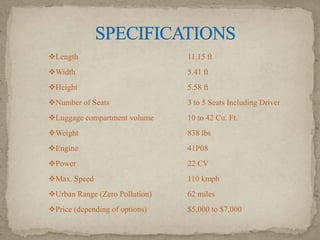

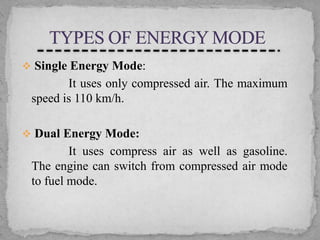

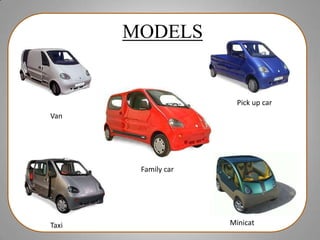

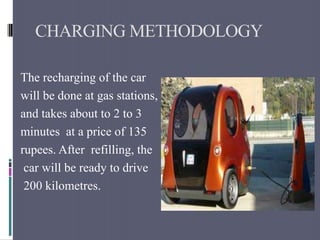

The document presents information on compressed air cars. It discusses how compressed air cars provide an alternative to gasoline-powered cars by using compressed air as fuel. The cars have a compressed air tank, air filter, chassis, and compressed air engine. The engine works similarly to a gasoline engine but uses compressed air instead of gasoline. Compressed air cars produce zero emissions and can be refueled quickly at gas stations using compressed air. While they have less speed than gasoline cars, compressed air cars provide a more sustainable transportation option.