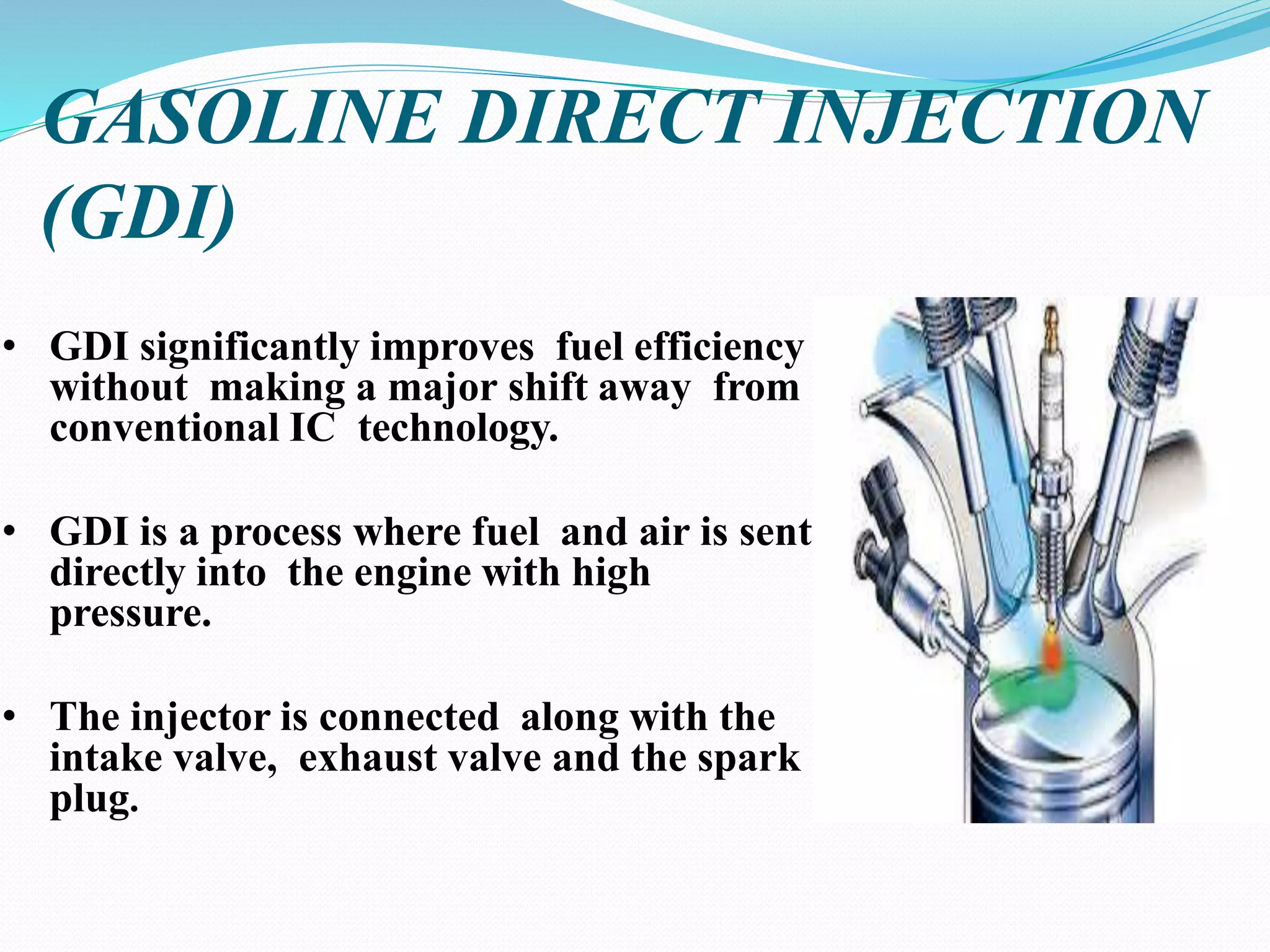

This document discusses different fuel injection systems used in internal combustion engines, including the advantages of gasoline direct injection (GDI) over traditional carburetors and port fuel injection. It describes how GDI works by injecting fuel directly into the combustion chamber under high pressure, allowing for improved fuel efficiency and reduced emissions compared to earlier fuel delivery methods. The key components of a GDI system are an engine control unit, sensors, high-pressure fuel pump, and fuel injectors. GDI provides benefits like lower fuel consumption, increased power and torque, and helps engines meet tighter emission standards.