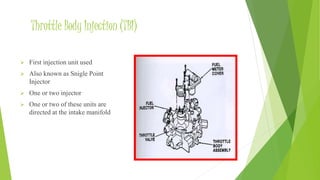

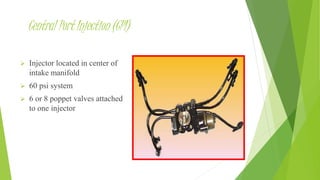

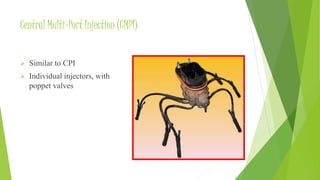

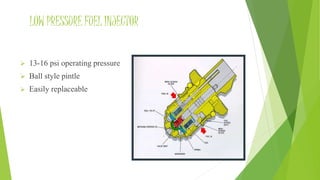

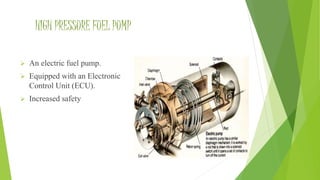

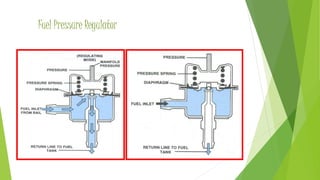

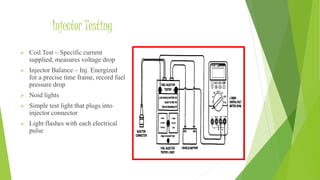

The document discusses electronic fuel injection systems. It provides an introduction and overview of the history and components of fuel injection systems. These include the electronic control unit, sensors, actuators, fuel injectors, fuel rail, and fuel pressure regulator. The document then describes how the fuel injection system and injectors work, the injector firing process, and testing and cleaning of injectors. It also discusses different fuel injection types and the advantages and disadvantages of electronic fuel injection systems.