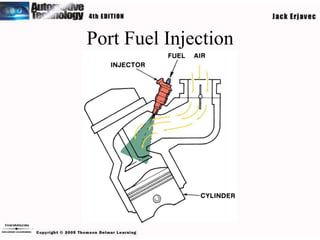

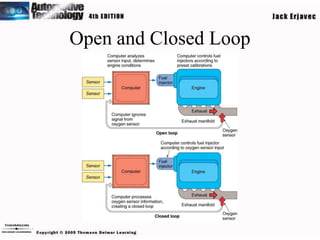

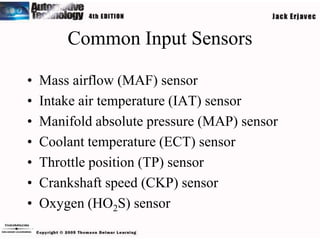

The document discusses electronic fuel injection systems and their components. It explains the differences between throttle body, port, and central port injection systems. The objectives are to describe the operation of major EFI components like fuel injectors, control modules, sensors that provide input on engine operation, and operating modes like open loop, closed loop, and clear flood. It also summarizes different types of port fuel injection firing systems and gasoline direct injection features and components.