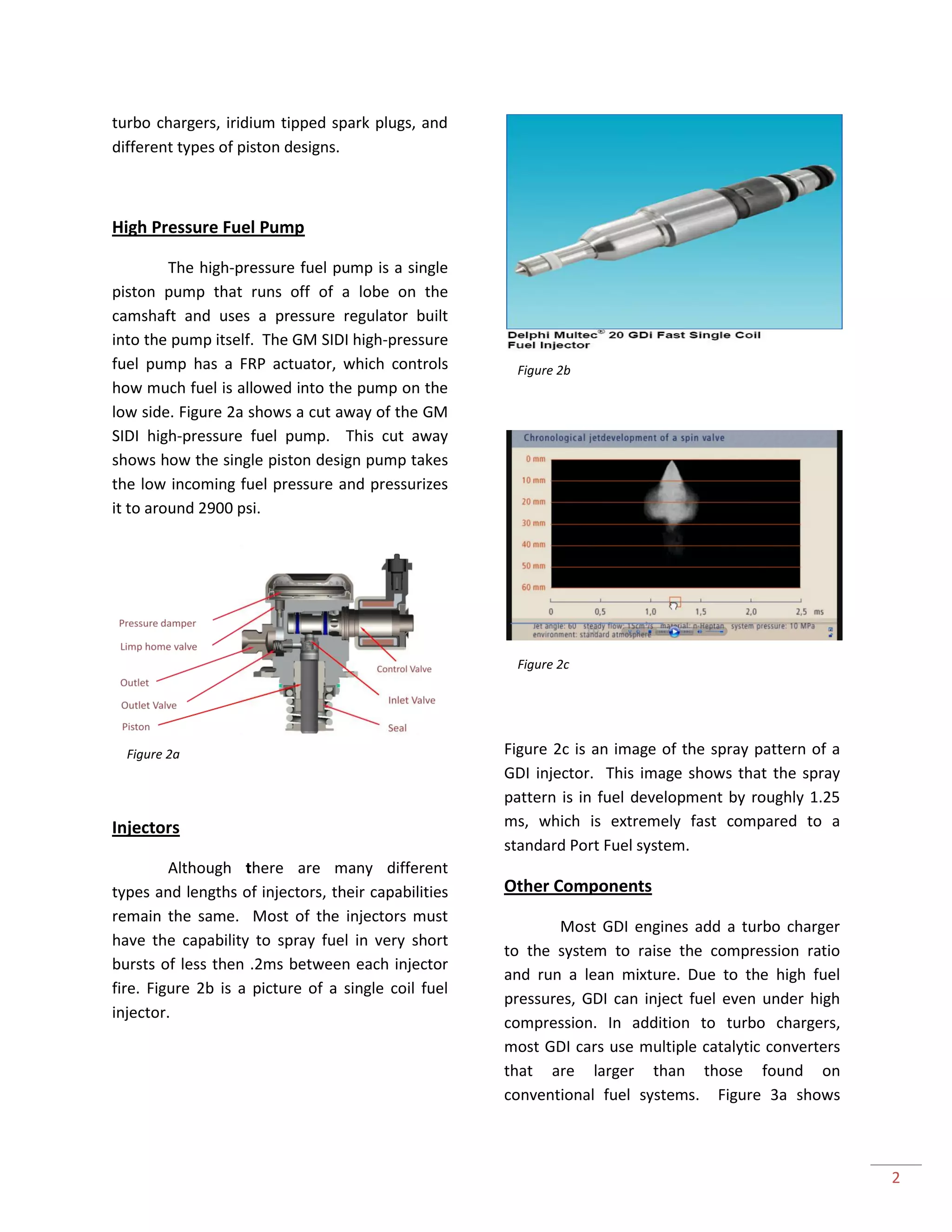

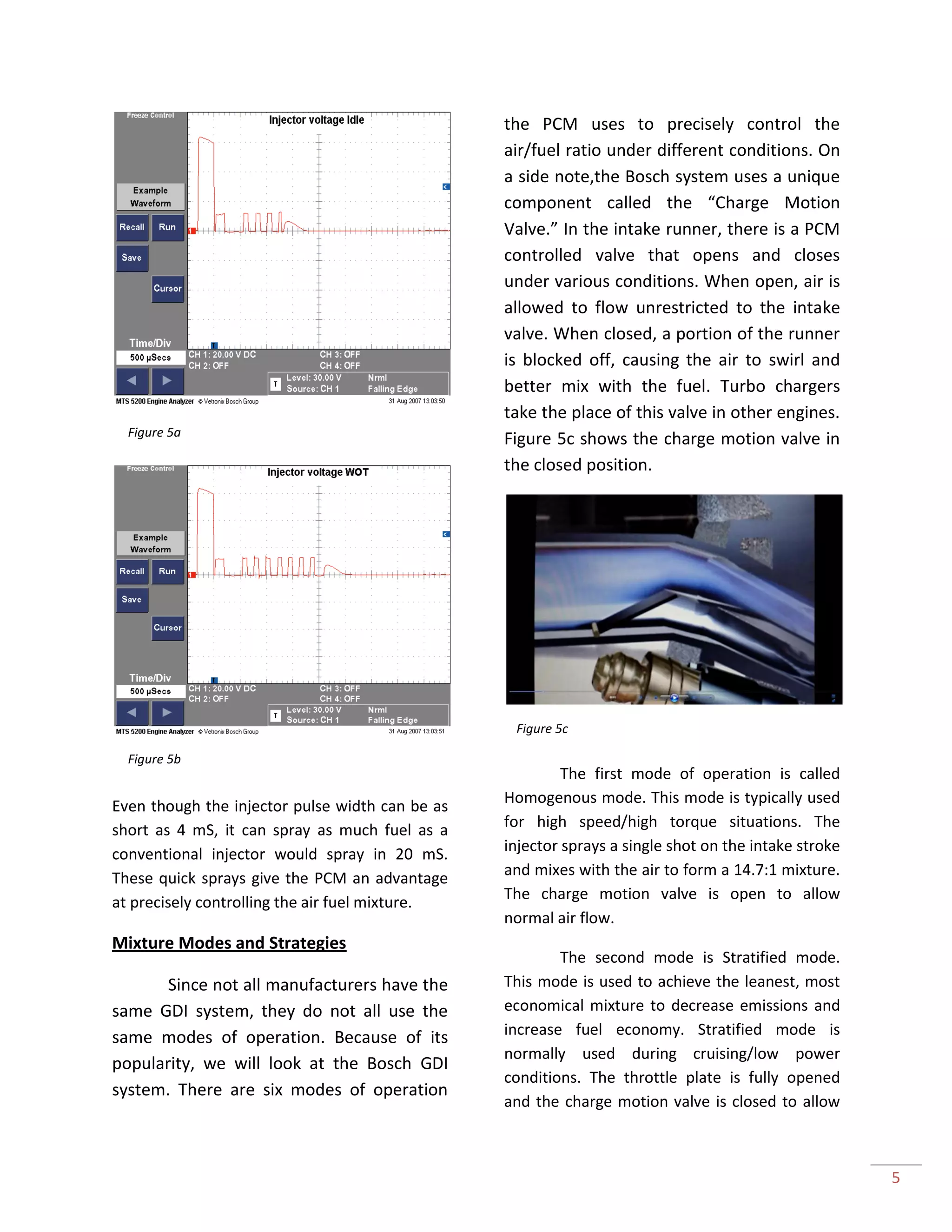

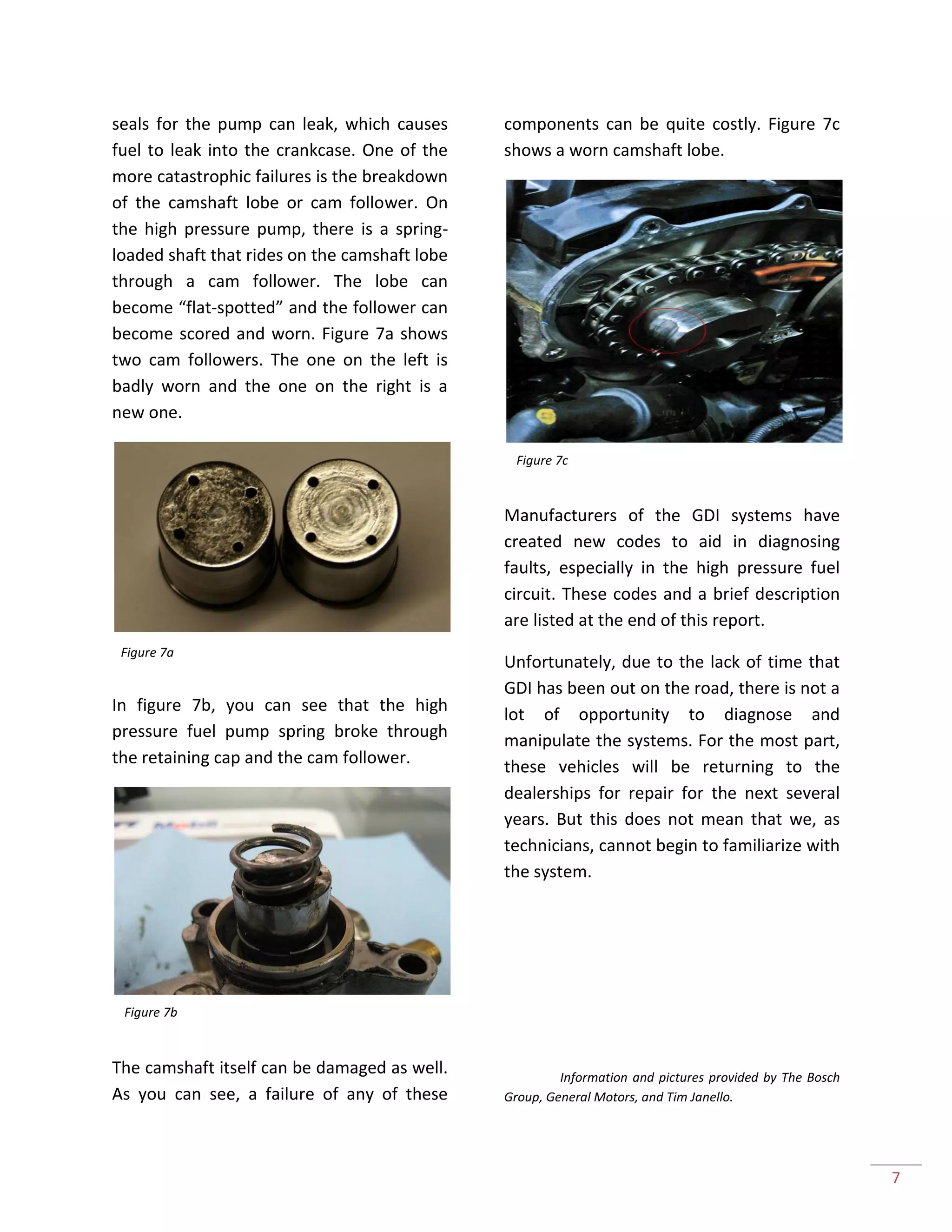

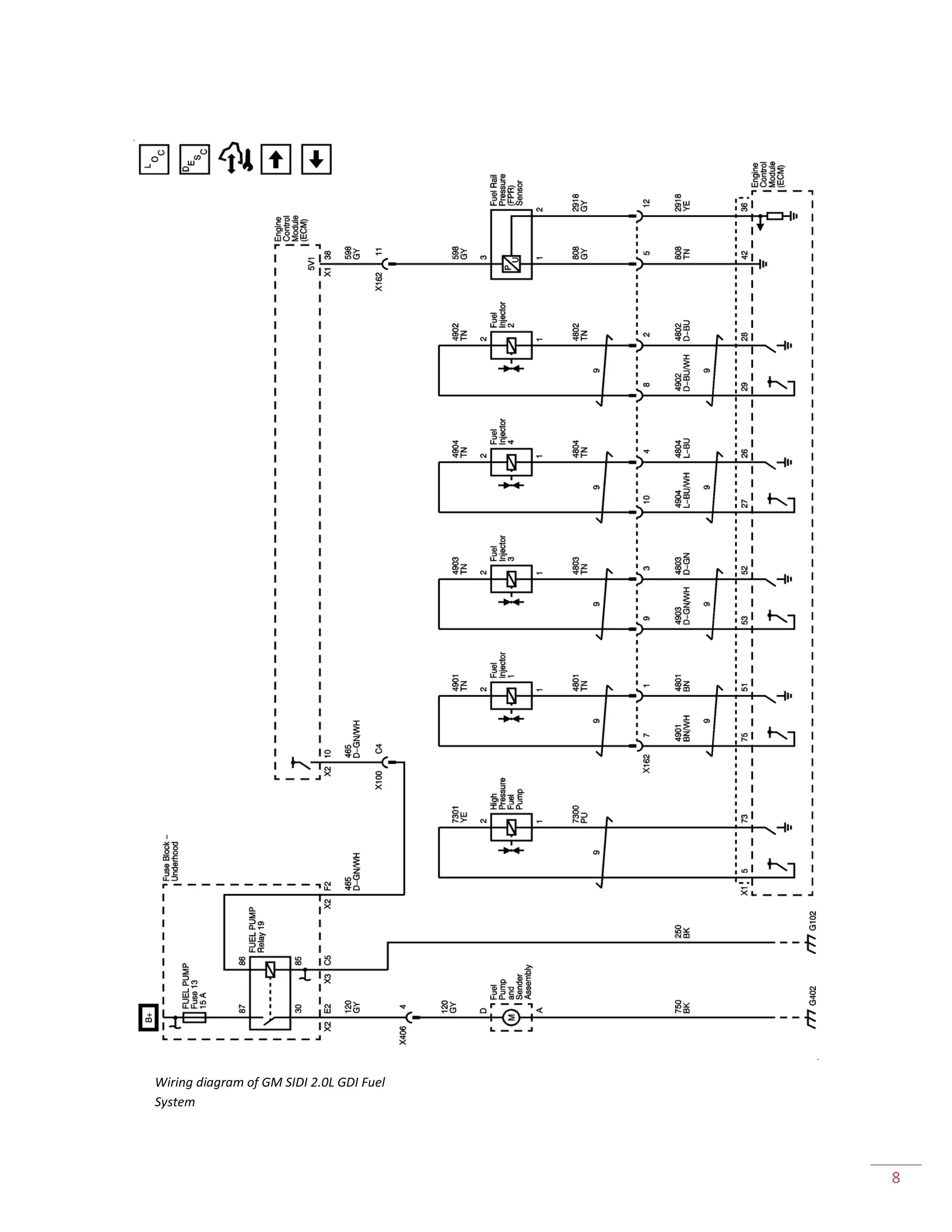

This document summarizes the technology and components of Gasoline Direct Injection (GDI) engines. It discusses how GDI systems work by directly injecting fuel into engine cylinders under high pressure, allowing for more precise fuel delivery than Port Fuel Injection. The key components of a GDI system include high-pressure fuel injectors, a high-pressure fuel pump, and an advanced PCM. The document also outlines several mixture modes that GDI engines use to optimize fuel economy and emissions, such as stratified mode which creates a rich fuel pattern near the spark plug.