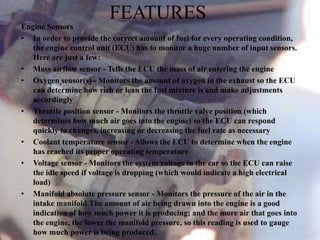

Fuel injection systems have replaced carburetors to meet stricter emissions standards. There are several types of fuel injection systems. Throttle body injection uses one or two fuel injectors in the throttle body. Multi-point fuel injection uses one injector per cylinder located at each intake port for more accurate fuel delivery. Sequential fuel injection improves upon multi-point by firing each injector just before the corresponding intake valve opens for better fuel efficiency and emissions control. Modern fuel injection systems precisely control fuel delivery through electronic management of injectors and sensors to maintain optimal air-fuel ratios.