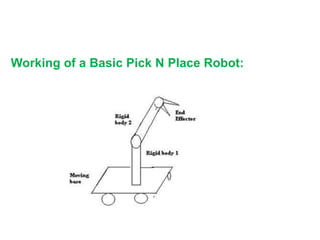

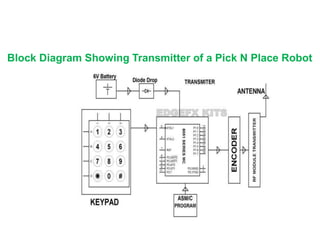

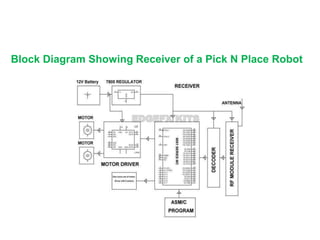

Pick N Place robots are used to pick up objects and place them in desired locations. They consist of a rover body with joints, an end effector for gripping objects, actuators like motors to move the robot, and sensors and a controller. The basic operation involves the wheels moving the base to the object's location, the rigid body bending to reach it, and the end effector picking up and placing the object. The robot can be controlled wirelessly via a keypad that sends commands to move motors in different directions. Pick N Place robots are used in manufacturing, defense applications like bomb diffusion, and medical operations for their accuracy and flexibility.