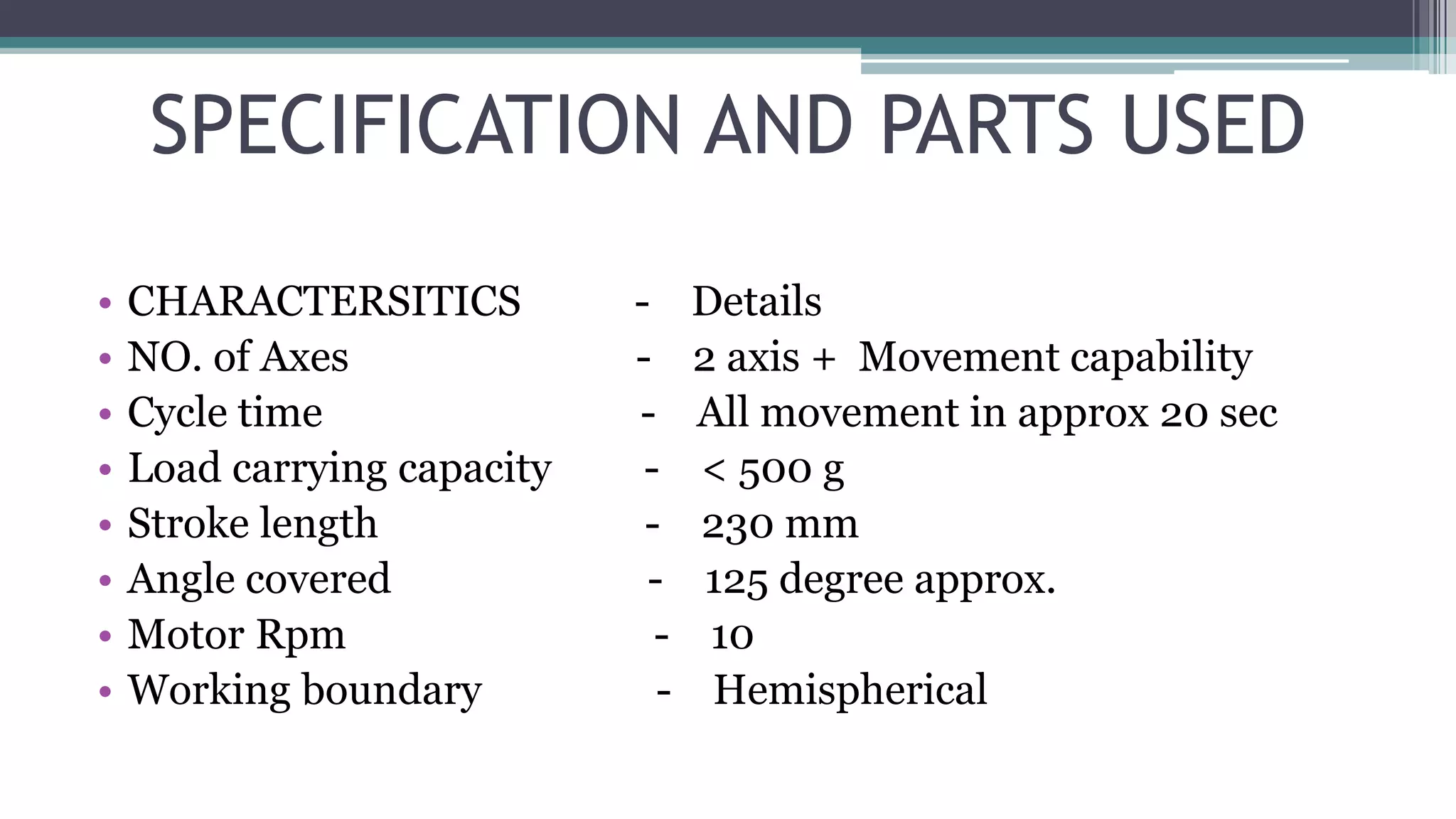

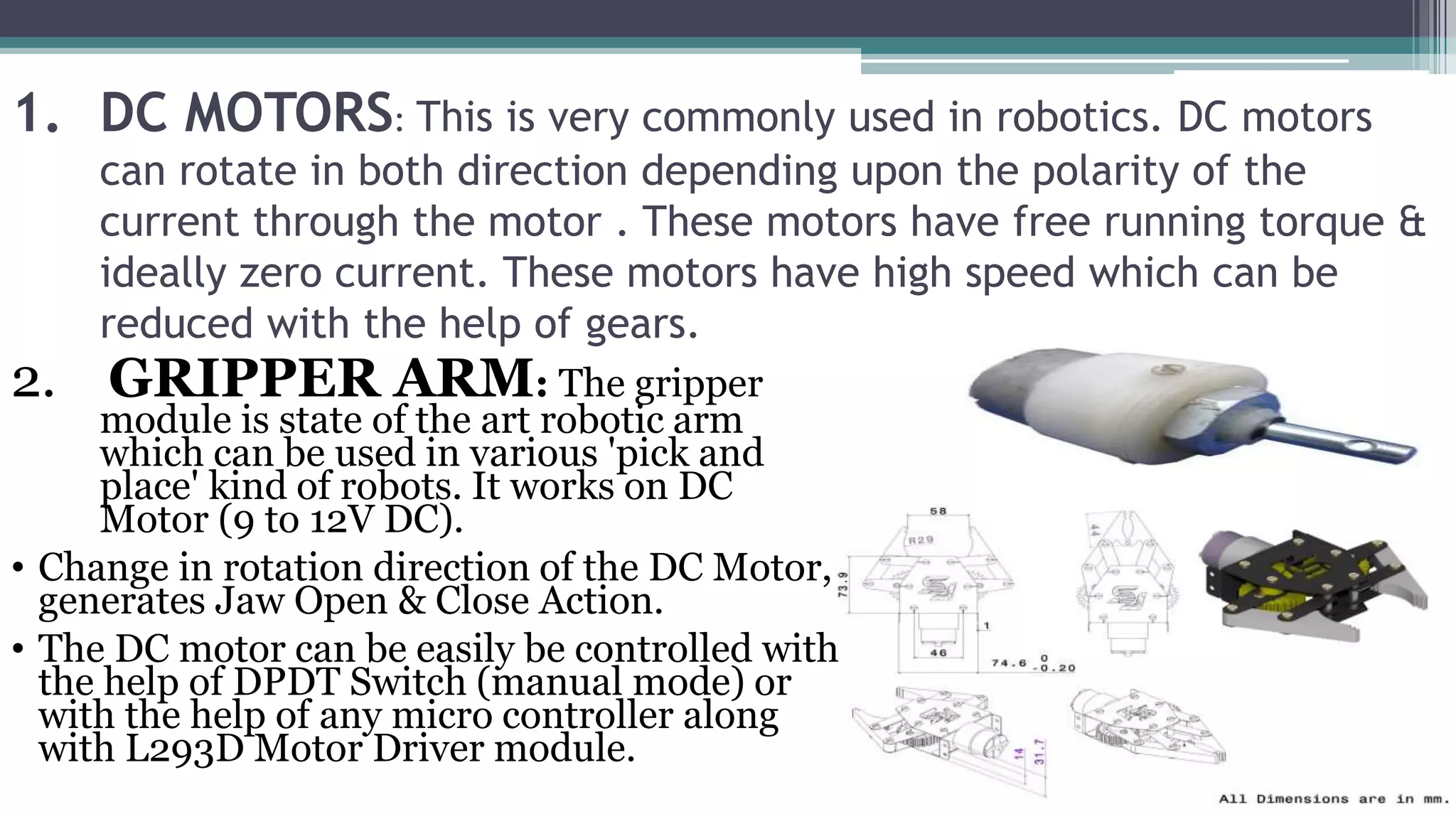

The document details the design and functionality of a mobile pick and place robot, emphasizing its components like DC motors, gripper arms, and drive mechanisms. This robot enhances automation in industrial settings by increasing speed, accuracy, and reliability while reducing manual labor costs. It discusses current applications, advantages, and potential future uses in various fields such as coal mining and waste disposal.