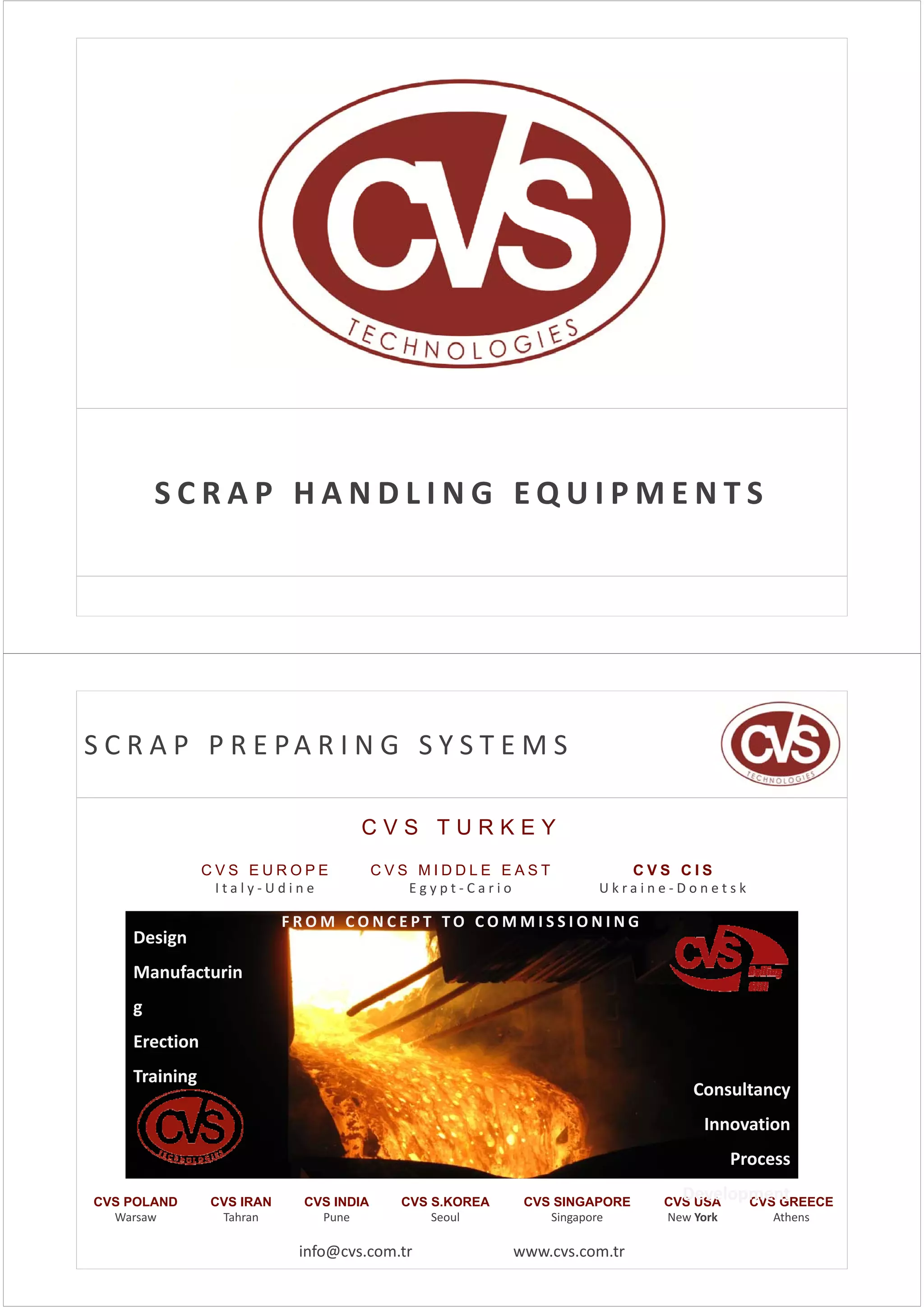

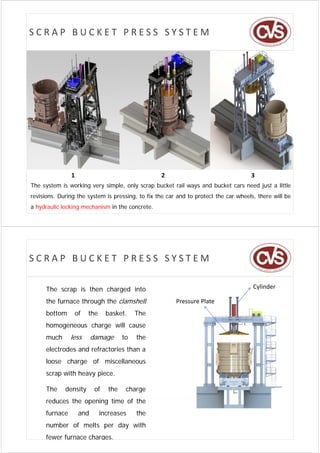

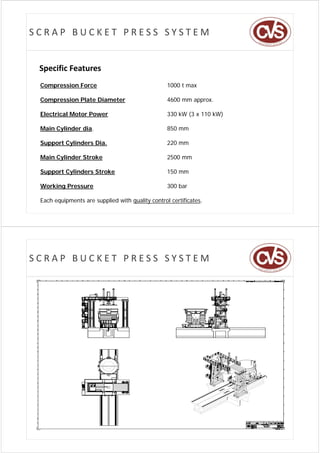

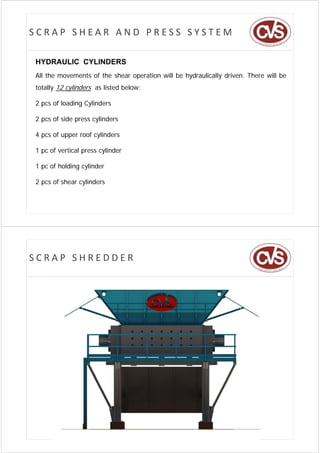

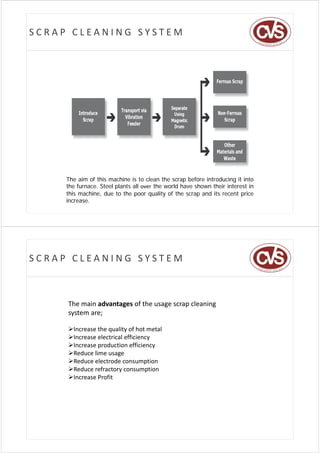

The document provides information on scrap handling equipment from CVS Makina, including scrap preparing systems, shear and press systems, shredders, pre-heating systems, and cleaning systems. CVS Makina designs and manufactures equipment for processing scrap metal to produce high density bales and ensure homogeneous furnace charges. The systems are designed for ease of maintenance and maximum productivity.