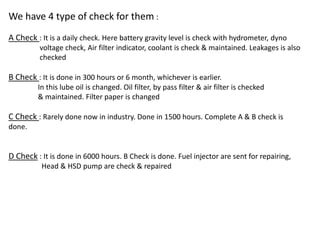

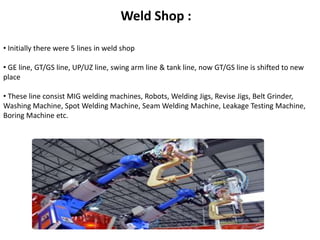

Suzuki's core philosophy is to provide value-packed products by developing them from the customer's point of view. This allows Suzuki to meet customer needs and have well-received products worldwide. The document then discusses the roles of the utility, maintenance, and various production departments like paint shop, welding, and press shop. It describes the key equipment used like generators, boilers, conveyors, injection molding machines, robots, and presses.