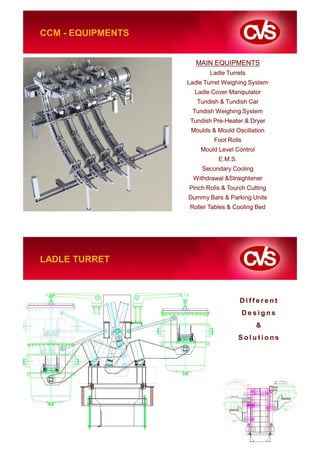

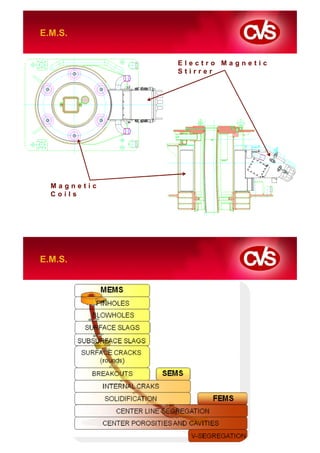

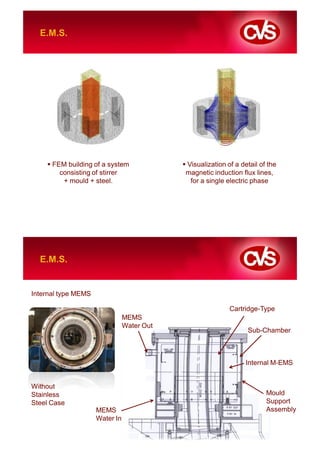

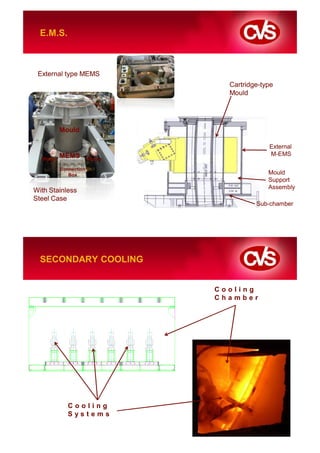

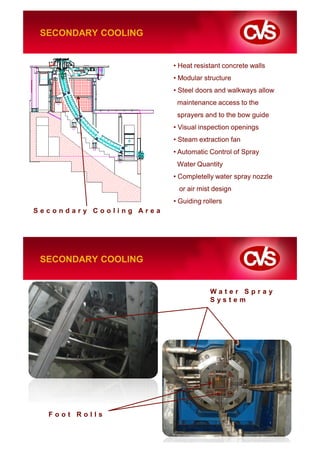

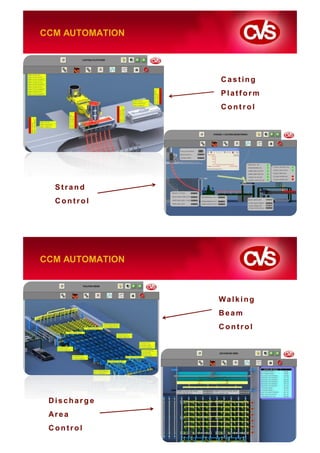

CVS is a company that provides design, manufacturing, installation, and consulting services for continuous casting machines (CCMs) and other steel production equipment. It has offices in Turkey and several other countries. CVS can customize CCMs to produce specific sections of billets or blooms and incorporates modern equipment like electromagnetic stirrers for quality control. The CCMs integrate various components and automation systems to continuously cast steel from ladle to cooling bed. CVS has extensive experience having completed many CCM projects worldwide.