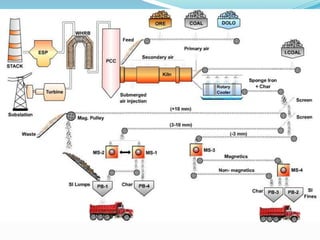

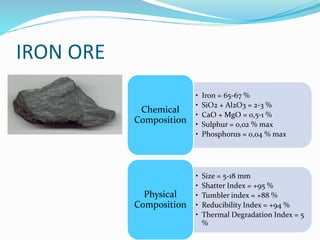

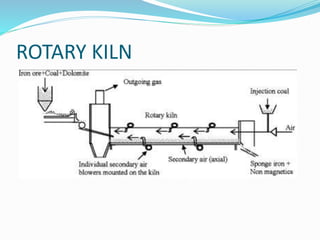

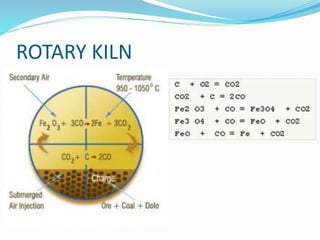

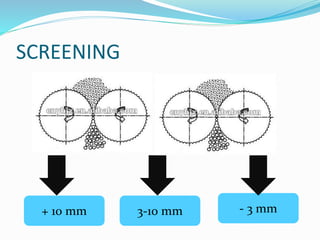

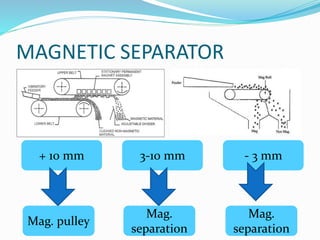

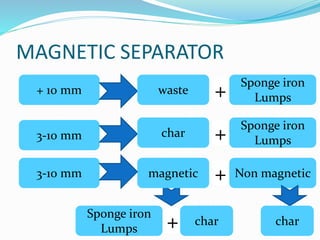

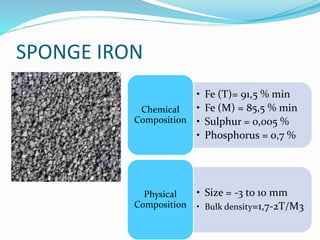

The document discusses the inputs and process for manufacturing sponge iron in a rotary kiln. It describes the chemical and physical composition of iron ore, coal, and dolomite that are fed into the kiln. It then outlines the rotary kiln process which involves preheating and combustion zones, use of primary and secondary air, coal injection, and rotary cooling before magnetic separation and screening to produce sponge iron and char as outputs. Waste heat is recovered to generate steam for power generation and gas is cleaned by an electrostatic precipitator before emission.