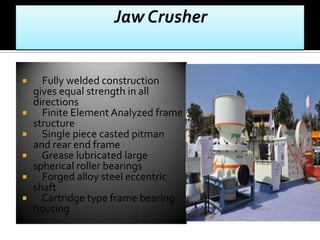

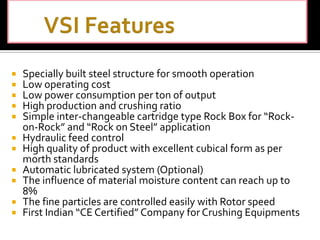

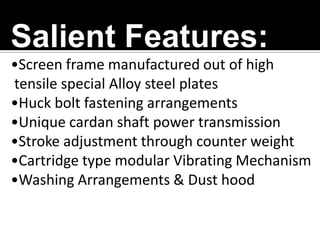

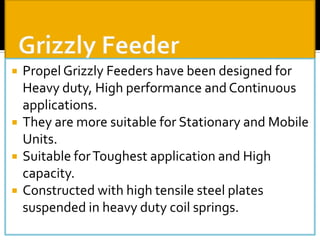

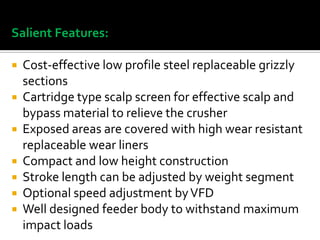

This document describes various types of equipment used in aggregate processing and mining industries, including jaw crushers, cone crushers, vertical shaft impactors, vibrating screens, grizzly feeders, and sand washers. It provides details on the construction, features, benefits, and specifications of each type of equipment. The equipment is designed for high productivity, low operating costs, durability, and optimal processing of aggregates and minerals.