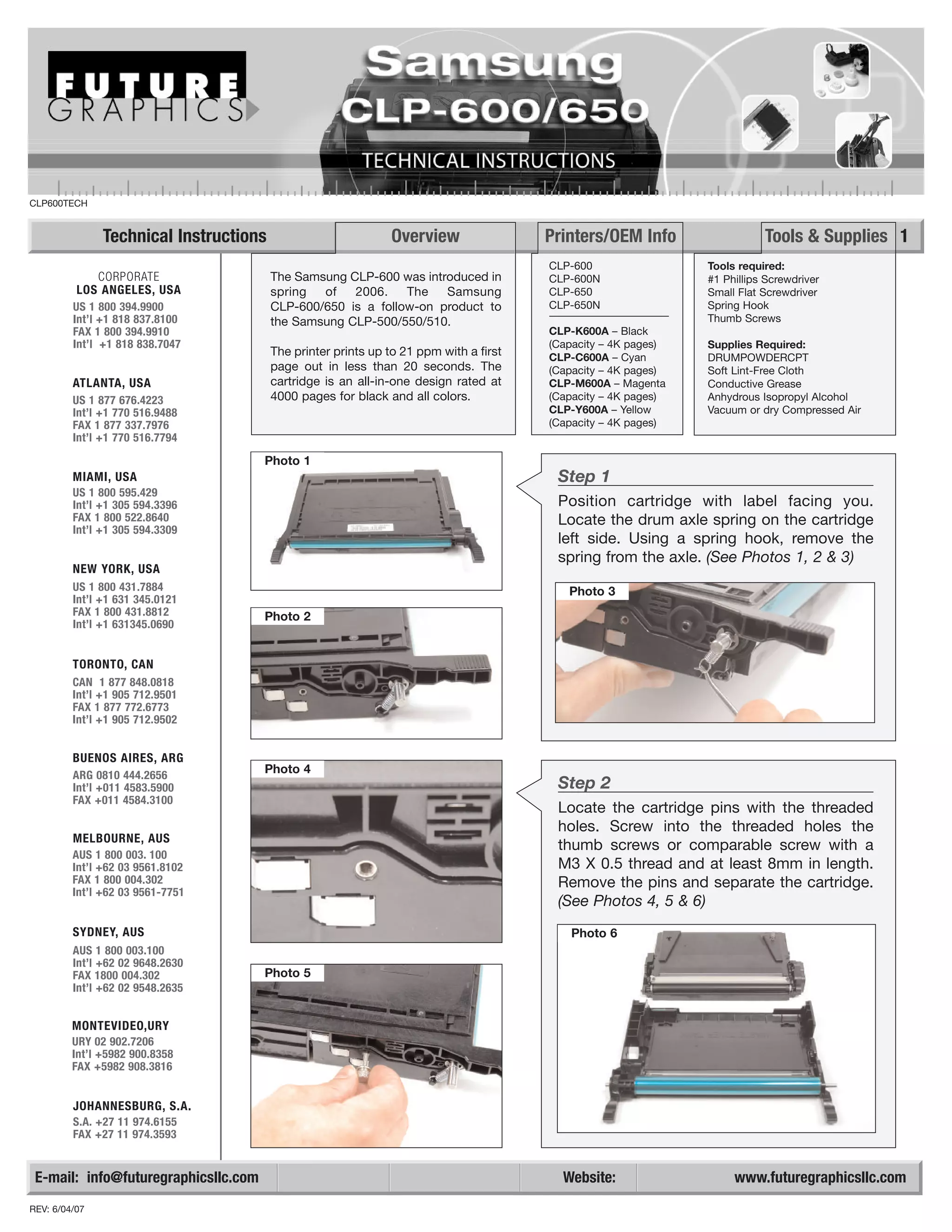

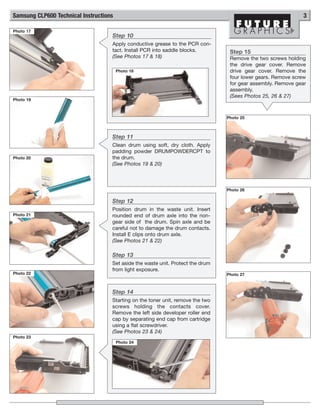

The document provides technical instructions for replacing components in the Samsung CLP-600 printer. It describes 20 steps for taking the printer cartridge apart and cleaning or replacing parts like the drum, developer roller, gears, and chip. Photos accompany each step to illustrate the process. The instructions are intended to guide replacement of parts with non-OEM alternatives supplied by Future Graphics.