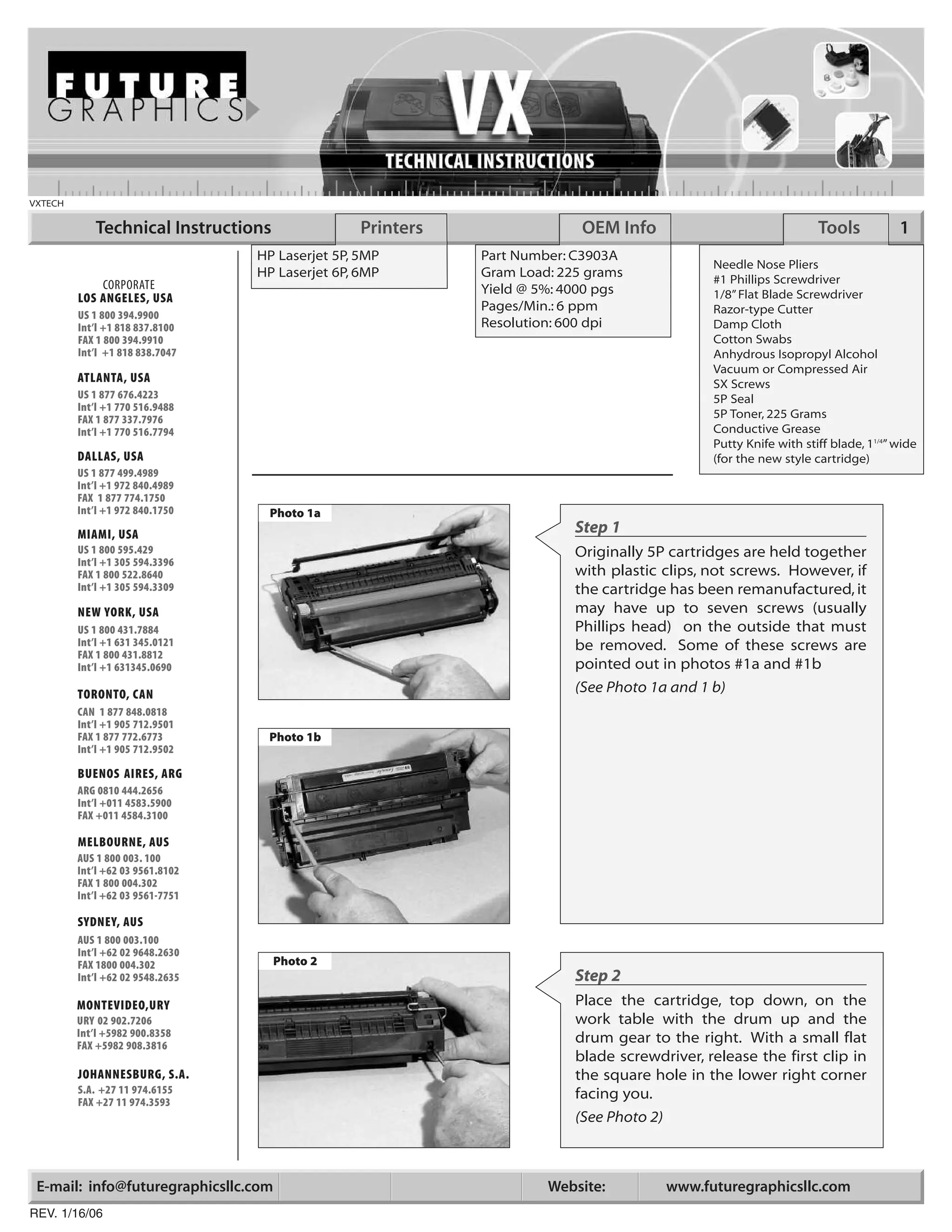

This document provides technical instructions for remanufacturing an HP Laserjet 5P or 6P toner cartridge. The instructions are presented in 27 steps with accompanying photos. The steps include separating the two halves of the cartridge, removing and cleaning internal components like the drum, doctor blade, and mag roller, replacing the toner seal, and refilling with new toner. Special instructions are provided for cartridges that were previously sealed with glue or foam.